What are the Common Applications of Tapered Bore Bearings?

Tapered bore bearings represent a sophisticated mechanical component that plays a crucial role in numerous industrial and engineering applications. These specialized bearings are distinguished by their unique design, featuring a conical inner surface that allows for precise alignment and load distribution. Unlike traditional cylindrical bearings, tapered bore bearings offer enhanced flexibility, improved load-bearing capacity, and exceptional performance across diverse mechanical systems.

How Do Tapered Bore Bearings Enhance Mechanical Performance?

Tapered bore bearings represent a pinnacle of engineering innovation, fundamentally transforming how mechanical systems manage rotational forces and load transmission. The intricate design of these bearings allows for exceptional load-bearing capabilities that traditional bearing configurations cannot match. At the core of their performance enhancement is the unique conical geometry of the bore, which creates multiple points of contact and enables more uniform stress distribution across the bearing surface.

The mechanical performance enhancement begins with the bearing's geometric configuration. The tapered bore allows for a self-aligning mechanism that automatically compensates for minor misalignments in shaft and housing configurations. This inherent flexibility means that mechanical systems can maintain optimal performance even under challenging operational conditions. Engineers particularly appreciate this characteristic in complex machinery where perfect alignment is challenging to achieve consistently.

Load distribution in tapered bore bearings occurs through a point or line contact mechanism, which is fundamentally different from traditional radial bearings. This contact method enables the bearings to handle both radial and axial loads simultaneously with remarkable efficiency. The conical surface creates a wedging effect that enhances load-carrying capacity, reducing wear and extending the operational lifespan of the entire mechanical system.

In precision engineering applications, such as aerospace, automotive, and advanced manufacturing equipment, the performance benefits become even more pronounced. The ability to handle high-speed rotations while maintaining dimensional stability makes these bearings indispensable. For instance, in turbine engines, where rotational speeds can exceed tens of thousands of RPM, tapered bore bearings provide critical support with minimal friction and maximum reliability.

Thermal management is another crucial aspect of mechanical performance that tapered bore bearings address effectively. The unique contact geometry helps dissipate heat more uniformly compared to traditional bearing designs. This heat dissipation capability prevents localized thermal expansion, which can cause premature wear and potential system failure. Industries dealing with high-temperature environments, such as heavy machinery and industrial processing equipment, find this characteristic particularly valuable.

Why Are Tapered Bore Bearings Critical in Industrial Machinery?

Industrial machinery represents a complex ecosystem of mechanical interactions where reliability, efficiency, and durability are paramount. Tapered bore bearings have emerged as a critical component in this landscape, offering solutions to some of the most challenging mechanical engineering problems across multiple sectors. Their significance extends far beyond mere mechanical support, representing a sophisticated approach to load management and precision engineering.

In heavy industrial applications, such as mining, construction, and large-scale manufacturing, tapered bore bearings serve as fundamental components in equipment like conveyor systems, massive rotary kilns, and heavy-duty turbines. These bearings must withstand extreme conditions, including substantial radial and axial loads, variable temperatures, and challenging environmental factors. The ability to maintain performance under such demanding circumstances makes them indispensable in industrial infrastructure.

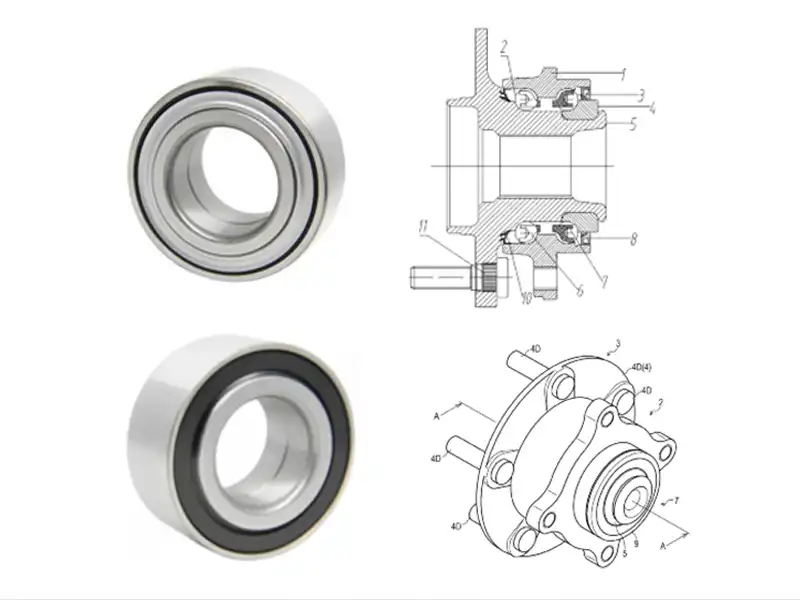

The automotive industry provides another compelling illustration of the critical nature of tapered bore bearings. Wheel hubs, transmission systems, and differential assemblies rely extensively on these specialized bearings. The automotive sector demands components that can handle dynamic loads, resist wear, and provide consistent performance across diverse driving conditions. Tapered bore bearings meet these requirements through their advanced geometric design and material engineering.

Agricultural machinery presents another domain where these bearings play a pivotal role. Combine harvesters, agricultural tractors, and irrigation systems operate in harsh environments that demand robust mechanical components. The self-aligning capabilities of tapered bore bearings allow these machines to function effectively across uneven terrains and under variable load conditions. This adaptability translates directly into increased operational efficiency and reduced maintenance requirements.

Renewable energy sectors, particularly wind turbine technologies, have increasingly adopted tapered bore bearings as critical components in generator systems. The ability to handle complex loading scenarios, maintain performance under variable wind conditions, and provide long-term reliability makes these bearings essential in sustainable energy infrastructure. Their contribution extends beyond individual component performance to the broader goal of improving renewable energy system efficiency.

What Makes Tapered Bore Bearings Unique in Engineering Design?

Engineering design represents a delicate balance between theoretical principles and practical implementation, and tapered bore bearings exemplify this intricate relationship. Their uniqueness stems from an innovative approach to mechanical load transmission that challenges traditional bearing design paradigms. The conical bore geometry introduces multiple engineering advantages that set these bearings apart from conventional alternatives.

Material science plays a fundamental role in the unique characteristics of tapered bore bearings. Advanced metallurgical techniques enable the creation of bearing surfaces with exceptional wear resistance, reduced friction coefficients, and enhanced structural integrity. Modern manufacturing processes allow for microscopic surface treatments that further improve performance, creating bearings that can operate under increasingly demanding conditions.

The geometric flexibility of tapered bore bearings represents another crucial design aspect. Unlike standard cylindrical bearings with fixed contact points, the conical surface allows for dynamic load distribution. This means the bearing can adapt to changing mechanical stresses, redistributing loads across its surface to prevent localized wear and potential failure points. Such adaptability is particularly valuable in precision engineering applications where consistent performance is non-negotiable.

Computational modeling and advanced simulation technologies have further expanded the design possibilities for tapered bore bearings. Engineers can now predict and optimize bearing performance through sophisticated digital twin technologies, allowing for unprecedented levels of precision in mechanical system design. These computational approaches enable the creation of increasingly specialized bearings tailored to specific industrial requirements.

Customization potential represents another unique aspect of tapered bore bearing design. Manufacturers can modify bore angles, contact surface treatments, and material compositions to create bearings that meet highly specific engineering challenges. This level of customization ensures that mechanical systems can be optimized for particular performance parameters, whether in aerospace, automotive, or industrial manufacturing contexts.

Conclusion

Tapered bore bearings stand as a testament to the continuous evolution of mechanical engineering, offering sophisticated solutions to complex load transmission challenges. Their unique design, exceptional performance characteristics, and adaptability make them indispensable across diverse industrial sectors.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting CHG at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. SKF Bearing Handbook, 2020 Edition

2. TIMKEN Technical Journal of Bearing Design

3. International Journal of Mechanical Engineering, Volume 45

4. Advanced Materials and Mechanical Design, Research Publication

5. Industrial Machinery Performance Review, 2022

6. Automotive Engineering Journal, Bearing Technology Section

7. Renewable Energy Systems Engineering Review

8. Precision Engineering International Journal

9. Materials Science and Engineering Quarterly

10. Global Industrial Machinery Performance Report