Are Cylindrical Thrust Roller Bearings Customizable?

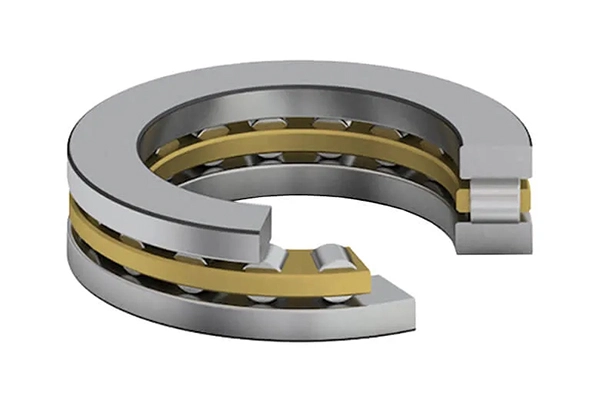

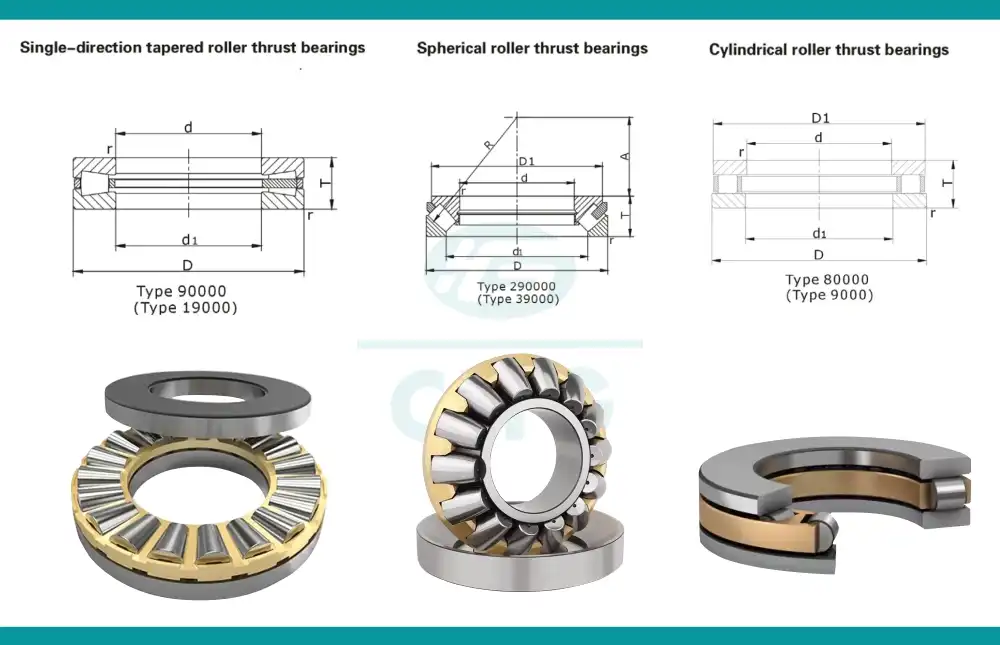

In the realm of industrial engineering, the ability to tailor components to specific operational needs is a game-changer, and this is particularly true for bearings. The question of whether Cylindrical Thrust Roller Bearings are customizable is highly relevant for industries seeking optimized performance in demanding applications. Cylindrical Thrust Roller Bearings are specialized components designed to handle significant axial loads, featuring cylindrical rollers arranged perpendicular to the shaft for efficient load distribution. Their robust design makes them indispensable in sectors like automotive, aerospace, and heavy machinery. Customization of these bearings can enhance their suitability for unique operational conditions, ensuring precision, durability, and efficiency. This blog delves into the customization potential of Cylindrical Thrust Roller Bearings, exploring how they can be adapted to meet diverse industrial requirements and the benefits this offers.

How Can Cylindrical Thrust Roller Bearings Be Tailored to Specific Applications?

Material Customization for Cylindrical Thrust Roller Bearings

Material selection is a critical aspect of customizing Cylindrical Thrust Roller Bearings to meet specific application needs. These bearings are typically made from high-quality steel, but customization allows for the use of alternative materials to enhance performance under unique conditions. For instance, in applications involving high temperatures, such as in steel mills, Cylindrical Thrust Roller Bearings can be manufactured using heat-resistant alloys to prevent thermal degradation. Similarly, in corrosive environments, such as marine or chemical processing industries, stainless steel or ceramic materials can be used to improve corrosion resistance. The ability to customize the material composition of Cylindrical Thrust Roller Bearings ensures that they can withstand extreme conditions, thereby extending their service life and improving the reliability of the machinery they support. This adaptability makes them a preferred choice for industries with specialized requirements.

Dimensional Adjustments in Cylindrical Thrust Roller Bearings

Dimensional customization is another key area where Cylindrical Thrust Roller Bearings can be tailored to specific applications. The size and configuration of these bearings, including the diameter, width, and roller dimensions, can be adjusted to fit the spatial constraints and load requirements of different machinery. For example, in compact automotive systems, such as clutch assemblies, Cylindrical Thrust Roller Bearings can be designed with reduced dimensions to fit within tight spaces while still handling significant axial loads. In contrast, for heavy industrial machinery like cranes or excavators, larger bearings with increased roller counts can be produced to support higher loads. This flexibility in dimensional design ensures that Cylindrical Thrust Roller Bearings can be seamlessly integrated into a wide range of equipment, enhancing their functionality and operational efficiency across diverse industries.

Load Capacity Enhancements in Cylindrical Thrust Roller Bearings

Customizing the load capacity of Cylindrical Thrust Roller Bearings is essential for applications with unique force dynamics. The load capacity of these bearings can be enhanced by modifying the number, size, and arrangement of the cylindrical rollers, as well as the design of the raceways. For instance, in high-load applications such as wind turbine gearboxes, Cylindrical Thrust Roller Bearings can be customized with additional rollers or larger roller diameters to increase their axial load-carrying capacity. Similarly, in precision machinery where stability is paramount, the roller arrangement can be optimized to ensure even load distribution and minimize vibration. This ability to tailor the load capacity of Cylindrical Thrust Roller Bearings ensures that they can meet the specific performance demands of various applications, making them a versatile solution for industries requiring robust and reliable bearing systems.

What Design Features Can Be Modified in Cylindrical Thrust Roller Bearings?

Cage Design Optimization for Cylindrical Thrust Roller Bearings

The cage design of Cylindrical Thrust Roller Bearings is a critical feature that can be customized to enhance performance in specific applications. The cage, which holds the cylindrical rollers in place, can be modified in terms of material, structure, and geometry to improve durability, reduce friction, and accommodate higher speeds. For example, in high-speed applications, such as automotive transmissions, the cage of Cylindrical Thrust Roller Bearings can be made from lightweight, high-strength materials like brass or polymer to minimize centrifugal forces and reduce heat generation. In heavy-duty industrial applications, such as mining equipment, a reinforced steel cage can be used to withstand extreme loads and harsh conditions. By optimizing the cage design, Cylindrical Thrust Roller Bearings can be tailored to meet the specific operational requirements of different industries, ensuring optimal performance and longevity.

Roller Configuration Adjustments in Cylindrical Thrust Roller Bearings

The configuration of the rollers in Cylindrical Thrust Roller Bearings is another design feature that can be customized to suit specific needs. The number, size, and arrangement of the rollers can be adjusted to optimize load distribution, stability, and efficiency. For instance, in applications requiring high axial load capacity, such as industrial presses, Cylindrical Thrust Roller Bearings can be designed with a higher number of rollers or larger roller diameters to increase the contact area and enhance load-carrying capacity. In contrast, for applications where space is limited, such as in aerospace components, a more compact roller configuration can be implemented to maintain performance within a smaller footprint. This flexibility in roller configuration allows Cylindrical Thrust Roller Bearings to be adapted to a wide range of operational conditions, making them a highly customizable solution for diverse industries.

Surface Treatment Enhancements for Cylindrical Thrust Roller Bearings

Surface treatments play a vital role in the customization of Cylindrical Thrust Roller Bearings, as they can significantly improve the bearings’ performance under specific conditions. Various surface treatments, such as coatings, heat treatments, and surface hardening, can be applied to the rollers and raceways to enhance wear resistance, reduce friction, and improve corrosion resistance. For example, in applications exposed to abrasive environments, such as construction machinery, Cylindrical Thrust Roller Bearings can be treated with a hard chrome coating to increase their durability. In high-speed applications, such as turbine engines, a low-friction coating can be applied to minimize heat generation and improve efficiency. These surface treatment enhancements ensure that Cylindrical Thrust Roller Bearings can be tailored to meet the unique challenges of different applications, providing reliable performance and extended service life.

How Do Custom Cylindrical Thrust Roller Bearings Benefit Industrial Applications?

Improved Efficiency with Custom Cylindrical Thrust Roller Bearings

Custom Cylindrical Thrust Roller Bearings offer significant efficiency improvements in industrial applications by being tailored to specific operational requirements. By optimizing features such as roller configuration, cage design, and surface treatments, these bearings can minimize friction, reduce energy consumption, and enhance overall machinery performance. For instance, in automotive applications like differential systems, custom Cylindrical Thrust Roller Bearings can be designed to reduce frictional losses, thereby improving fuel efficiency. In industrial machinery, such as conveyor systems, customized bearings can enhance throughput by ensuring smooth and efficient operation under heavy loads. The ability to tailor Cylindrical Thrust Roller Bearings to specific efficiency needs ensures that they contribute to the overall productivity and cost-effectiveness of industrial systems, making them a valuable asset in performance-driven environments.

Enhanced Durability Through Custom Cylindrical Thrust Roller Bearings

Durability is a key benefit of custom Cylindrical Thrust Roller Bearings, as their tailored design ensures they can withstand the specific stresses and conditions of their intended applications. By customizing materials, surface treatments, and load capacities, these bearings can be made more resistant to wear, fatigue, and environmental factors, thereby extending their service life. For example, in heavy-duty applications like steel rolling mills, custom Cylindrical Thrust Roller Bearings can be designed with reinforced materials and coatings to endure extreme pressures and temperatures. In marine applications, corrosion-resistant materials can be used to protect against saltwater exposure. This enhanced durability reduces the frequency of maintenance and replacements, providing a cost-effective solution for industries that rely on reliable, long-lasting bearing systems, and ensuring uninterrupted operation in critical applications.

Versatility Across Industries with Custom Cylindrical Thrust Roller Bearings

The versatility of custom Cylindrical Thrust Roller Bearings is a major advantage, as their adaptability allows them to be used across a wide range of industries with diverse operational needs. By tailoring features such as dimensions, materials, and load capacities, these bearings can be designed to meet the specific requirements of applications in automotive, aerospace, energy, and heavy machinery sectors. For instance, in the aerospace industry, custom Cylindrical Thrust Roller Bearings can be designed for compact, high-precision components in landing gear systems, while in the energy sector, they can be tailored for large-scale wind turbine gearboxes. This versatility ensures that Cylindrical Thrust Roller Bearings can address the unique challenges of different industries, providing tailored solutions that enhance performance, reliability, and efficiency across a broad spectrum of applications.

Conclusion

In conclusion, Cylindrical Thrust Roller Bearings are highly customizable, offering tailored solutions that enhance performance, durability, and efficiency across various industrial applications. By modifying materials, dimensions, load capacities, cage designs, roller configurations, and surface treatments, these bearings can be adapted to meet the specific needs of diverse industries, ensuring optimal functionality and longevity. The ability to customize Cylindrical Thrust Roller Bearings underscores their versatility and value in modern engineering, making them an essential component in achieving operational excellence.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T. A., & Kotzalas, M. N. (2006). Rolling Bearing Analysis: Essential Concepts of Bearing Technology. CRC Press.

2. Brändlein, J., Eschmann, P., Hasbargen, L., & Weigand, K. (1999). Ball and Roller Bearings: Theory, Design, and Application. Wiley.

3. Shigley, J. E., & Mischke, C. R. (2001). Mechanical Engineering Design. McGraw-Hill.

4. Palmgren, A. (1959). Ball and Roller Bearing Engineering. SKF Industries.

5. Hamrock, B. J., Schmid, S. R., & Jacobson, B. O. (2004). Fundamentals of Machine Elements. McGraw-Hill.

6. Stachowiak, G. W., & Batchelor, A. W. (2013). Engineering Tribology. Butterworth-Heinemann.