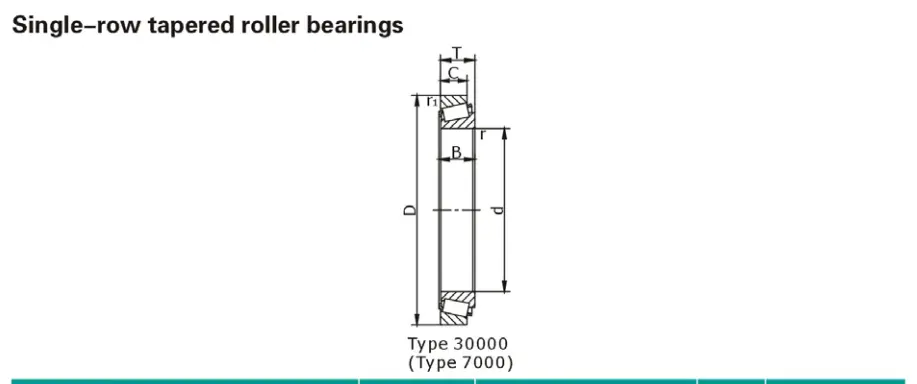

Single Row Tapered Roller Bearing

2. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

3.Features: TSingle row tapered roller bearings primarily carry combined loads which is main in radial, and tapered roller bearings with large tapered angle (27°-30°) primarily carry combined loads which is main in axial but nor pure axial loads.

4. Application:rear axle hubs of automotives, large machine tool spindles, large power reducer, roller wheels of feedways.

5. Advantage: These bearings can limit axial displacement of shafts or housings in one direction. The inner and outer rings can be mounted respectively as separable structure, the other rings are interchangeable, and they are easy to mounted and dismounted. The radial and axial clearance can be adjusted during mounting or working, and also can be interference mounted to crease stiffness.

What is a Single Row Tapered Roller Bearing?

A Single Row Tapered Roller Bearing is a high-precision component designed to handle radial and axial loads simultaneously. These orientations highlight decreased rollers organized in a single push, making them perfect for applications requiring bolster for overwhelming loads and tall speeds. Their interesting plan guarantees that the rollers come into contact with the raceway at a single point, permitting them to effectively disperse loads and decrease contact.

Why Choose CHG Bearing for Your Single Row Tapered Roller Bearings?

At CHG Bearing, we take pride in being a leading manufacturer and supplier of the products. Here’s why you should consider us:

Customization and Solutions: We offer tailored solutions to meet your specific working conditions. Whether you need a bearing for high-speed operations or extreme load-bearing requirements, our team can design and produce bearings that fit your needs.

30 Years of Industry Experience: With three decades of expertise in the bearing industry, we have established strong partnerships with major companies worldwide.

Innovative and Certified: CHG Bearing holds over 50 invention patents and complies with international standards.

For inquiries and orders, please contact us at sale@chg-bearing.com.

Technical Specifications

| Specification | Details |

|---|---|

| Bearing Type | Single Row Tapered Roller Bearing |

| Bore Diameter | Customizable |

| Outer Diameter | Customizable |

| Width | Customizable |

| Load Capacity | High Load Capacity |

| Material | High-Quality Steel |

| Temperature Range | High-Temperature Capable |

| Sealing | Optional Seals Available |

Benefits of Single Row Tapered Roller Bearings

- High Load Capacity: Designed to handle both radial and axial loads, making them ideal for heavy-duty applications.

- Precision Engineering: Ensures smooth and reliable operation, reducing maintenance needs and extending service life.

- Versatility: Suitable for a wide range of applications, from mining machinery to metallurgical equipment.

- Reduced Friction: The tapered design minimizes friction and heat generation, improving efficiency and performance.

Applications

Single Row Tapered Roller Bearing is widely used in various industries due to its robustness and reliability.

- Metallurgical Industry: Used in blast furnaces, rolling mills, and steelmaking equipment.

- Mining Machinery: Ideal for jaw crushers, impact crushers, vibrating screens, and feeders.

- Automotive Industry: Employed in vehicle wheel hubs and differential assemblies.

- Construction Machinery: Supports components in heavy-duty construction equipment.

Production Process

Installation Guide

Proper installation is crucial for the optimal performance of the products. Follow these steps:

- Clean the Bearings and Housing: Ensure all surfaces are free from contaminants.

- Apply Lubrication: Use appropriate lubricants as per the manufacturer’s specifications.

- Position the Bearing: Align the bearing accurately in the housing to avoid misalignment.

- Press Fit: Carefully press the bearing into place using a proper tool to avoid damage.

- Check Alignment: Verify that the bearing is correctly aligned to prevent premature wear.

Maintenance and Care

To ensure the longevity and performance of your products, follow these maintenance tips:

- Regular Inspections: Check for signs of wear, damage, or contamination.

- Proper Lubrication: Maintain appropriate lubrication levels to reduce friction and wear.

- Monitor Operating Conditions: Keep an eye on temperature and load conditions to prevent overloads.

- Clean Environment: Ensure the working environment is clean to minimize contamination.

FAQ

Q1: What are the advantages of Single Row Tapered Roller Bearings over other types? A1: They offer high load capacity, precision, and versatility, making them suitable for demanding applications.

Q2: How do I choose the right product for my application? A2: Consider factors such as load capacity, operating conditions, and size requirements. Consult with our experts for customized solutions.

Q3: What maintenance is required for these bearings? A3: Regular inspections, proper lubrication, and monitoring of operating conditions are essential for maintaining performance.

Customer Reviews

John D., Mining Equipment Manager: “CHG Bearing’s products have been a game-changer for our machinery. Reliable and high-performance!”

Lisa R., Production Engineer: “The customization options and quick delivery from CHG Bearing helped us meet tight deadlines. Highly recommend!”

Contact Us

For more information or to place an order, feel free to reach out to us:

Email: sale@chg-bearing.com

Website: www.chg-bearing.com

Experience unparalleled performance and precision with CHG Bearing’s Single Row Tapered Roller Bearing. Contact us today to find out how we can support your needs!

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | |||||||||

| mm | kN | Current | Original | kg | r/min | ||||||||

| d | D | T | B | C | rmin | r1min | Cr | Cor | Grease | Oil | |||

| 150 | 270 | 77 | 73 | 60 | 4 | 3 | 718 | 1200 | 32230 | 7530E | 18.2 | 1200 | 1700 |

| 320 | 114 | 108 | 90 | 5 | 4 | 1110 | 1580 | 32330 | 7630 | 37.1 | 950 | 1400 | |

| 160 | 240 | 51 | 51 | 38 | 3 | 2.5 | 420 | 735 | 32032 | 2007132E | 7.7 | 1200 | 1700 |

| 340 | 75 | 68 | 58 | 5 | 4 | 765 | 960 | 30332 | 7332E | 28.4 | 1000 | 1500 | |

| 340 | 121 | 114 | 95 | 5 | 4 | 1210 | 1770 | 32332 | 7632 | 48.3 | 950 | 1400 | |

| 170 | 230 | 32 | 30 | 23 | 3 | 3 | 200 | 400 | 70DB170 | - | 3 | 1200 | 1700 |

| 310 | 91 | 86 | 71 | 5 | 4 | 835 | 1320 | 32234 | 7534E | 27.6 | 1000 | 1500 | |

| 360 | 80 | 72 | 62 | 5 | 4 | 950 | 1400 | 30334 | 7334E | 35 | 950 | 1400 | |

| 360 | 127 | 120 | 100 | 5 | 4 | 975 | 1764 | 32334 | 7634 | 58.3 | 1000 | 1300 | |

| 180 | 280 | 64 | 60 | 52 | 3 | 2.5 | 540 | 890 | 32036X2 | 2007136 | 13 | 1100 | 1600 |

| 280 | 64 | 64 | 48 | 3 | 2.5 | 569 | 950 | 32036 | 2007136E | 14 | 1100 | 1600 | |

| 320 | 57 | 52 | 43 | 5 | 4 | 610 | 912 | 30236 | 7236E | 17.8 | 1000 | 1500 | |

| 320 | 91 | 86 | 71 | 5 | 4 | 998 | 1727 | 32236 | 7536E | 29.8 | 950 | 1400 | |

| 190 | 260 | 45 | 42 | 36 | 2.5 | 2 | 292 | 580 | 32938X2 | 2007938 | 6.52 | 1000 | 1400 |

| 290 | 51 | 46 | 40 | 3 | 2.5 | 435 | 365 | - | 7138 | 10.5 | 1000 | 1500 | |

| 290 | 64 | 60 | 52 | 3 | 2.5 | 502 | 932 | 32038X2 | 2007138 | 14.2 | 950 | 1300 | |

| 290 | 64 | 64 | 48 | 3 | 2.5 | 520 | 950 | 32038 | 2007138E | 15.6 | 950 | 1300 | |

| 340 | 97 | 92 | 75 | 5 | 4 | 1117 | 1919 | 32238 | 7538E | 36.1 | 900 | 1300 | |

| 200 | 280 | 51 | 48 | 41 | 3 | 2.5 | 345 | 710 | 32940X2 | 2007940 | 8.86 | 950 | 1300 |

| 280 | 51 | 51 | 39 | 3 | 2.5 | 460 | 950 | 32940 | 2007940E | 9.5 | 950 | 1300 | |

| 310 | 70 | 66 | 56 | 3 | 2.5 | 575 | 1120 | 32040X2 | 2007140 | 17.9 | 900 | 1200 | |

| 310 | 70 | 70 | 53 | 3 | 2.5 | 650 | 1300 | 32040 | 2007140E | 18.9 | 900 | 1200 | |

| 360 | 64 | 58 | 48 | 5 | 4 | 765 | 1140 | 30240 | 7240E | 25.4 | 900 | 1300 | |

| 360 | 104 | 98 | 82 | 5 | 4 | 1090 | 1750 | 32240 | 7540E | 43.2 | 900 | 1300 | |

| 205 | 485 | 117.5 | 100 | 75 | 4 | 4 | 1400 | 2020 | 30641 | 7841E | 95 | 850 | 1200 |

| 210 | 420 | 90 | 81 | 67 | 6 | 5 | 1280 | 1910 | - | 7342X2 | 56 | 850 | 1200 |

| 220 | 300 | 51 | 48 | 41 | 3 | 2.5 | 425 | 855 | 32944X2 | 2007944 | 10.2 | 900 | 1200 |

| 340 | 76 | 72 | 62 | 4 | 3 | 702 | 1330 | 32044X2 | 2007144 | 22.2 | 800 | 1000 | |

| 340 | 76 | 76 | 57 | 4 | 3 | 750 | 1350 | 32044 | 2007144E | 24.4 | 800 | 1000 | |

| 400 | 72 | 65 | 54 | 4 | 3 | 810 | 1150 | 30244 | 7244E | 35.4 | 850 | 1200 | |

| 400 | 114 | 108 | 90 | 4 | 3 | 1320 | 2210 | 32244 | 7544E | 48.1 | 800 | 1100 | |

| 240 | 320 | 51 | 48 | 41 | 3 | 2.5 | 390 | 860 | 32948X2 | 2007948 | 10.8 | 800 | 1000 |

| 360 | 76 | 72 | 62 | 4 | 3 | 710 | 1420 | 32048X2 | 2007148 | 23.8 | 700 | 900 | |

| 360 | 76 | 76 | 57 | 4 | 3 | 850 | 1560 | 32048 | 2007148E | 20.4 | 700 | 900 | |

| 440 | 127 | 120 | 100 | 4 | 4 | 1630 | 2730 | 32248 | 7548 | 81.3 | 750 | 1000 | |

| 260 | 360 | 63.5 | 60 | 52 | 3 | 2.5 | 525 | 1150 | 32952X2 | 2007952 | 19.2 | 700 | 900 |

| 360 | 63.5 | 63.5 | 48 | 3 | 2.5 | 550 | 1300 | 32952 | 2007952E | 20 | 700 | 900 | |

| 400 | 87 | 82 | 71 | 5 | 4 | 902 | 1810 | 32052X2 | 2007152 | 36.9 | 670 | 850 | |

| 400 | 87 | 87 | 65 | 5 | 4 | 1010 | 1850 | 32052 | 2007152E | 37 | 670 | 850 | |

| 540 | 114 | 102 | 85 | 6 | 6 | 2014 | 2898 | 30352X2 | 7352 | 111 | 670 | 900 | |

| 270 | 420 | 87 | 87 | 65 | 5 | 4 | 1150 | 2060 | 32054 | 2007154 | 45 | 600 | 750 |

| 280 | 350 | 36 | 33 | 26 | 2 | 2 | 279 | 469 | 30656 | 1007856 | 6.33 | 870 | 1100 |

| 380 | 63.5 | 63.5 | 48 | 3 | 2.5 | 635 | 1300 | 32956 | 2007956E | 19.8 | 800 | 1100 | |

| 420 | 87 | 82 | 71 | 5 | 4 | 622 | 1940 | 32056X2 | 2007156 | 39.6 | 600 | 750 | |

| 420 | 87 | 87 | 65 | 5 | 4 | 1170 | 2230 | 32056 | 2007156E | 40.4 | 600 | 750 | |

| 300 | 420 | 76 | 76 | 57 | 4 | 3 | 998 | 2128 | 32960 | 2007960E | 28.7 | 700 | 950 |

| 440 | 73 | 70 | 55 | 4 | 3 | 959 | 2062 | 30660 | 7860 | 30.7 | 570 | 600 | |

| 460 | 100 | 95 | 82 | 5 | 4 | 1050 | 2190 | 32060X2 | 2007160 | 55.9 | 560 | 700 | |

| 500 | 95 | 90 | 70 | 4 | 4 | 1225 | 2207 | 31160X2 | 1007760 | 67.7 | 530 | 670 | |

| 320 | 440 | 76 | 72 | 62 | 4 | 3 | 1040 | 2320 | 32964X2 | 2007964 | 44.7 | 560 | 700 |

| 440 | 76 | 76 | 57 | 4 | 3 | 962 | 2040 | 32964 | 2007964E | 33 | 560 | 700 | |

| 480 | 100 | 95 | 82 | 5 | 4 | 1050 | 2190 | 32064X2 | 2007164 | 59 | 530 | 670 | |

| 480 | 100 | 100 | 74 | 5 | 4 | 1649 | 3192 | 32064 | 2007164E | 60 | 530 | 670 | |

| 580 | 110 | 105 | 80 | 6 | 6 | 2100 | 3100 | - | 7264 | 114 | 480 | 600 | |

| 340 | 460 | 76 | 72 | 62 | 4 | 3 | 611 | 1428 | 32968X2 | 2007968 | 34.3 | 530 | 670 |

| 520 | 86 | 82 | 64 | 4 | 4 | 807 | 1540 | 32068X2 | 7168 | 57 | 500 | 630 | |

| 520 | 112 | 106 | 92 | 6 | 6 | 1660 | 3370 | 32068 | - | 86.5 | 500 | 630 | |

| 580 | 106 | 102 | 87 | 6 | 5 | 1840 | 2970 | - | 7768 | 109 | 480 | 600 | |

| 360 | 480 | 76 | 72 | 62 | 4 | 3 | 634 | 1526 | 32972X2 | 2007972 | 35.9 | 500 | 630 |

| 540 | 86 | 82 | 64 | 4 | 4 | 919 | 1848 | 31072X2 | 7172 | 60.5 | 480 | 600 | |

| 650 | 170 | 155 | 140 | 5 | 6 | 3580 | 6000 | 32272X2 | - | 175 | 380 | 480 | |

| 380 | 520 | 66.5 | 65 | 46.5 | 3 | 3 | 529 | 1138 | 31976X2 | 1007976 | 37.5 | 480 | 600 |

| 520 | 87 | 82 | 71 | 5 | 4 | 800 | 1600 | 32976X2 | 2007976 | 42.7 | 480 | 600 | |

| 620 | 112 | 106 | 76 | 4 | 4 | 909 | 1708 | 31176X2 | 1007776 | 114 | 400 | 500 | |

| 400 | 500 | 60 | 57 | 47 | 4 | 3 | 665 | 775 | - | 7880 | 45.7 | 450 | 530 |

| 540 | 70 | 65 | 51 | 3 | 3 | 1000 | 2070 | 31980X2 | 1007980 | 43.2 | 450 | 530 | |

| 540 | 87 | 82 | 71 | 5 | 4 | 1130 | 2760 | 32980X2 | 2007980 | 57 | 450 | 530 | |

| 600 | 95 | 90 | 67 | 4 | 4 | 1040 | 2128 | 31080X2 | 7180 | 84 | 400 | 500 | |

| 420 | 560 | 70 | 65 | 51 | 3 | 3 | 630 | 1383 | 31984X2 | 1007984 | 42.4 | 400 | 500 |

| 560 | 87 | 82 | 72 | 5 | 4 | 1250 | 2870 | 32984X2 | 2007984 | 46 | 400 | 500 | |

| 560 | 87 | 87 | 67 | 5 | 4 | 1250 | 2870 | R420-5 | - | 47 | 400 | 500 | |

| 620 | 95 | 90 | 70 | 4 | 4 | 1132 | 2422 | 31084X2 | 7184 | 88 | 380 | 480 | |

| 700 | 130 | 122 | 92 | 6 | 6 | 1620 | 2800 | 31184X2 | 1007784 | 183 | 310 | 420 | |

| 440 | 650 | 96.4 | 94 | 67 | 6 | 4 | 1193 | 2422 | 31088X2 | 7188 | 99 | 360 | 450 |

| 460 | 620 | 80 | 74 | 58 | 3 | 3 | 836 | 1834 | 31992X2 | 1007992 | 59.8 | 380 | 480 |

| 680 | 105 | 100 | 78 | 6 | 6 | 1680 | 3550 | 31092X2 | 7192 | 118 | 330 | 450 | |

| 480 | 650 | 84.2 | 78 | 60 | 4 | 4 | 854 | 1918 | 31996X2 | 1007996 | 71 | 340 | 430 |

| 500 | 720 | 110 | 100 | 82 | 6 | 6 | 1459 | 3192 | 310/500X2 | 71/500 | 135 | 280 | 360 |

| 530 | 710 | 88 | 82 | 62 | 4 | 4 | 1001 | 2380 | 319/530X2 | 10079/530 | 94.8 | 280 | 360 |

| 560 | 750 | 92.5 | 85 | 64 | 4 | 4 | 1001 | 2576 | 319/560X2 | 10079/560 | 104 | 240 | 320 |

| 820 | 121 | 115 | 84 | 6 | 6 | 1887 | 4046 | 310/560X2 | 71/560 | 191 | 220 | 300 | |

| 600 | 870 | 124 | 118 | 89 | 6 | 6 | 2020 | 4438 | 310/600X2 | 71/600 | 235 | 180 | 240 |

| 630 | 920 | 135 | 128 | 94 | 7.5 | 7.5 | 2315 | 5222 | 310/630X2 | 71/630 | 278 | 170 | 220 |

| 710 | 950 | 114 | 106 | 80 | 6 | 6 | 1765 | 4494 | 319/710X2 | 10079/710 | 210 | 150 | 190 |

| 760 | 890 | 78 | 75 | 56 | 6 | 6 | 1510 | 1960 | - | 78/760 | 78.3 | 280 | 380 |

| 800 | 1060 | 122 | 115 | 89 | 6 | 6 | 2132 | 5530 | 319/800X2 | 10079/800 | 275 | 130 | 170 |

| 900 | 1180 | 124 | 122 | 87 | 6 | 6 | 2173 | 5782 | 319/900X2 | 10079/900 | 330 | 95 | 130 |

| 1280 | 190 | 170 | 135 | 7.5 | 7.5 | 5615 | 13913 | 320/900X2 | 71/900 | 703 | 95 | 130 | |

| 950 | 1250 | 140 | 132 | 100 | 7.5 | 7.5 | 3930 | 10427 | 319/950X2 | 10079/950 | 428 | 80 | 100 |

YOU MAY LIKE

VIEW MORENu Cylindrical Roller Bearing

VIEW MORENu Cylindrical Roller Bearing VIEW MORESingle Row Spherical Roller Bearing

VIEW MORESingle Row Spherical Roller Bearing VIEW MOREDouble Row Spherical Roller Bearing

VIEW MOREDouble Row Spherical Roller Bearing VIEW MORECylindrical Bearing

VIEW MORECylindrical Bearing VIEW MOREConical Roller Bearing

VIEW MOREConical Roller Bearing VIEW MORESingle Row Cylindrical Roller Bearing

VIEW MORESingle Row Cylindrical Roller Bearing VIEW MOREFour Row Tapered Roller Bearing

VIEW MOREFour Row Tapered Roller Bearing VIEW MORECylindrical Roller Bearings

VIEW MORECylindrical Roller Bearings