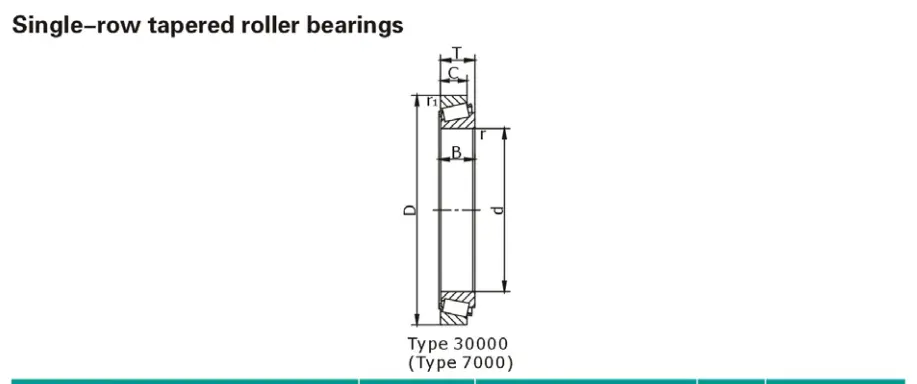

Conical Roller Bearing

2. Application: Tapered roller bearings are widely used in rear axle hubs of automotives, large machine tool spindles, large power reducer, roller wheels of feedways.

3. Matched Type: face to face, back to back, in tandet

4. Size range: Inter diameter:150-950mm

5. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

What is a Conical Roller Bearing?

A Conical Roller Bearing, also known as a tapered roller bearing, is a specialized type of bearing designed to handle both radial and axial loads efficiently. The bearing features tapered inner and outer ring raceways with conical rollers positioned between them. This unique design allows the bearing to support large load capacities and provides excellent durability, making it ideal for heavy-duty applications. Products are commonly used in industries such as metallurgy, mining, and heavy machinery, where equipment must operate under high-stress conditions.

Why Choose CHG Bearing?

CHG Bearing is a leading manufacturer and supplier of products, with over 30 years of industry experience. Our commitment to quality, innovation, and customer satisfaction has made us a trusted partner for many large companies worldwide. Here's why CHG Bearing stands out:

Customization and Solutions: We understand that different working conditions require tailored solutions. CHG Bearing offers customization services to meet your specific needs, ensuring that our bearings perform optimally in your applications.

Industry Experience: With over three decades of experience, CHG Bearing has deep industry knowledge and expertise. Our long-standing relationships with major companies testify to our reliability and quality.

Patents and Certifications: CHG Bearing holds over 50 invention patents and has passed rigorous quality and environmental certifications, including ISO9001 and ISO14001. We are committed to maintaining the highest standards in every aspect of our business.

For more information or to discuss your specific requirements, please contact us at sale@chg-bearing.com.

Technical Specifications

Below are the key technical specifications for our conical roller bearings:

| Parameter | Specification |

|---|---|

| Inner Diameter (mm) | 20 - 150 |

| Outer Diameter (mm) | 40 - 250 |

| Width (mm) | 15 - 100 |

| Material | High-Grade Steel |

| Load Capacity | Up to 500,000 N |

| Operating Temperature | -40°C to 120°C |

| Lubrication | Grease or Oil |

| Certification | ISO9001, ISO14001, GJB9001C-2017 |

Conical Roller Bearing Benefits

Choosing conical roller bearings from CHG Bearing offers several advantages:

High Precision and Quality: Our bearings are engineered to deliver precise operation, which is critical for maintaining the stability and performance of your equipment.

Long Life and Wear Resistance: Designed for harsh environments, our bearings offer exceptional durability and wear resistance, reducing the need for frequent replacements and lowering maintenance costs.

Customizability: We provide customized solutions to meet the unique demands of your equipment and operating conditions, ensuring optimal performance.

Cost-Effective Solutions: CHG Bearing offers high-quality products at competitive prices, providing excellent value for your investment.

Applications

Our products are versatile and used in various industries:Metallurgical Industry: Essential for large rotating equipment like blast furnaces, rolling mills, and steelmaking machinery.

Mining Machinery: Widely used in jaw crushers, impact crushers, vibrating screens, and feeders, where high load capacity and durability are critical.

Heavy Machinery: Ideal for applications requiring support for high radial and axial loads, ensuring smooth operation and longevity of the equipment.

Installation Guide

Installing a product requires careful attention to detail to ensure optimal performance:

Preparation: Clean the bearing housing and shaft thoroughly to remove any debris or contaminants.

Alignment: Ensure the bearing is aligned correctly with the shaft and housing to prevent uneven wear and premature failure.

Lubrication: Apply the recommended lubricant to the bearing before installation. CHG Bearing offers bearings pre-lubricated with grease or oil.

Mounting: Use appropriate tools to mount the bearing securely, avoiding excessive force that could damage the bearing components.

Testing: After installation, rotate the bearing assembly by hand to check for smooth operation and proper alignment.

Maintenance and Care

Proper maintenance can significantly extend the life of your conical roller bearings:

Regular Inspection: Check bearings regularly for signs of wear, corrosion, or damage.

Re-lubrication: Periodically re-lubricate the bearings according to the manufacturer’s recommendations to ensure smooth operation.

Temperature Monitoring: Keep an eye on operating temperatures. Excessive heat could indicate issues with lubrication or alignment.

Vibration Analysis: Use vibration analysis to detect early signs of bearing failure, allowing for proactive maintenance.

FAQ

Q1: How long do conical roller bearings last?

A: The lifespan of a product depends on several factors, including operating conditions, load, and maintenance. Under optimal conditions, they can last for several years.

Q2: Can I customize the size of a bearing?

A: Yes, CHG Bearing offers customization services to meet specific requirements. Please contact us to discuss your needs.

Q3: What is the delivery time for custom orders?

A: Delivery times vary based on the complexity of the customization and current production schedules. We strive to provide fast and reliable delivery to meet urgent needs.

Customer Reviews

"CHG Bearing's conical roller bearings have significantly improved the reliability of our equipment. Their quality and durability are unmatched!" – John D., Production Manager

"We have been using CHG Bearing for years, and their customization service is top-notch. Highly recommended!" – Sarah L., Technical Engineer

Contact Us

For more information or to place an order, please contact our sales team:

- Email: sale@chg-bearing.com

- Website: www.chg-bearing.com