Spherical Roller Bearing

These bearings are able to carry high radial loads, as well as axial loads at the same time, but not pure axial loads, the axial carrying bearing will be needed if axial loads were higher. The contact between rollers and raceways are so close, so the friction is higher than cylindrical roller bearings, and their limiting speed is lower.

2. Application:

Spherical roller bearings are primarily used in such application as rolling mills, paper making machines,power-driven gears, shipping and so on.

3. Sizes:Inner Diameter: 150-1060mm

Outer Diameter: 225-1400mm Weight: 8.91-1020kg

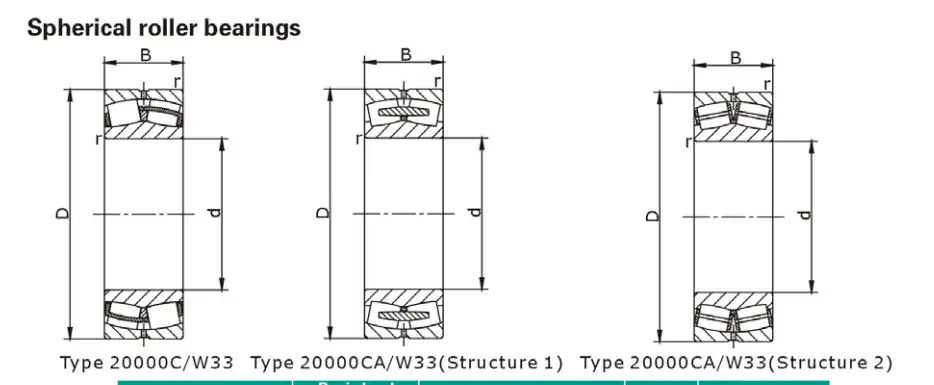

4: Type: 20000C, 20000C/W33, 20000CA/W33

5. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

What is a Spherical Roller Bearing?

A spherical roller bearing is a robust type of rolling bearing designed to handle heavy loads and severe operating conditions. Unlike other bearings, it feature two rows of barrel-shaped rollers that accommodate both radial and axial loads, making them ideal for applications involving substantial stresses and misalignments.

These bearings are engineered to support rotating equipment in various industries, including metallurgy, mining, and manufacturing. Their unique design allows them to self-align and absorb misalignment between the shaft and the housing, ensuring smooth and efficient operation even under challenging conditions.

CHG Bearing: Your Trusted Partner for Spherical Roller Bearings

CHG Bearing stands out as a leading manufacturer and supplier of it. With over 30 years of industry experience, we provide tailored solutions to meet the specific demands of various working conditions. Our bearings are engineered to deliver exceptional performance, durability, and reliability.

Why Choose CHG Bearing?

Customization and Solutions: We offer bespoke solutions to match the unique requirements of your equipment and operational environment. Whether you need customized sizes, materials, or lubrication methods, we have the expertise to meet your needs.

Industry Expertise: With three decades of experience, CHG Bearing has partnered with numerous large-scale companies across various sectors. Our deep understanding of industrial applications ensures that we deliver high-quality bearings suited for even the most demanding environments.

Innovative Excellence: Our company holds more than 50 invention patents and adheres to rigorous quality standards. We are certified under ISO9001 for quality management and ISO14001 for environmental management, reflecting our commitment to excellence and sustainability.

For personalized support and to discuss your specific requirements, please contact us at sale@chg-bearing.com.

Technical Specifications

| Specification | Details |

|---|---|

| Bearing Type | Spherical Roller Bearing |

| Inner Diameter | Customizable |

| Outer Diameter | Customizable |

| Width | Customizable |

| Load Capacity | High Load Capacity |

| Material | High-Quality Steel |

| Seals | Optional |

| Lubrication | Grease or Oil |

Benefits of Spherical Roller Bearings

- Self-Aligning Capability: Automatically adjusts to misalignments, reducing stress on the equipment and extending its service life.

- High Load Bearing: Capable of supporting heavy radial and axial loads, making them suitable for heavy-duty applications.

- Durability and Reliability: Built to withstand harsh environments and high-impact loads, minimizing maintenance needs and downtime.

- Versatility: Ideal for a wide range of applications, including rolling mills, crushers, and large-scale industrial machinery.

Applications

Spherical roller bearings are extensively used in various sectors, including:

- Metallurgical Industry: Essential in blast furnaces, rolling mills, and steelmaking equipment.

- Mining Machinery: Utilized in jaw crushers, impact crushers, vibrating screens, and feeders.

- Manufacturing: Employed in large rotating equipment and heavy-duty machinery.

Installation Guide

- Preparation: Ensure the bearing and housing are clean and free from contaminants.

- Alignment: Properly align the bearing with the shaft and housing to avoid misalignment.

- Press Fitting: Use a press to install the bearing onto the shaft, ensuring even pressure distribution.

- Lubrication: Apply the recommended lubricant to the bearing to ensure smooth operation.

- Final Check: Verify alignment and fit, and ensure there are no signs of interference.

Maintenance and Care

- Regular Inspection: Check for signs of wear, vibration, or abnormal noise.

- Lubrication: Reapply lubricant as per the manufacturer’s recommendations to maintain performance.

- Cleanliness: Keep the bearing and surrounding area clean to prevent contamination.

FAQ

Q: What industries use this roller bearings?

A: They are widely used in metallurgy, mining, and manufacturing industries, particularly in applications requiring high load capacities and reliability.

Q: How can I customize a spherical roller bearing for my equipment?

A: Contact CHG Bearing with your specific requirements, including dimensions, materials, and lubrication methods. We offer bespoke solutions tailored to your needs.

Q: What maintenance is required for this roller bearings?

A: Regular inspection, proper lubrication, and maintaining cleanliness are crucial for optimal performance and longevity.

Customer Reviews

John D., Production Manager:

"CHG Bearing's bearings have significantly improved the reliability of our machinery. Their quick response and customized solutions are invaluable."

Maria L., Technical Engineer:

"The quality and durability of CHG's bearings are outstanding. They meet the demanding requirements of our equipment perfectly."

Contact Us

For more information about our spherical roller bearings or to request a quote, please reach out to us at:

Email: sale@chg-bearing.com

| Boundary dimensions | Basic load ratings | Part number | Installation | Constant | Axial | Mass | Limiting speeds | ||||||||||

| (mm) | |||||||||||||||||

| mm | kN | Current | Original | dbmin | Damin | ramax | e | Y2 | Y3 | Y0 | kg | r/min | |||||

| d | D | B | rmin | Cr | Cor | Grease | Oil | ||||||||||

| 150 | 225 | 56 | 2.1 | 338 | 768 | 23030 | 3003130 | 162 | 213 | 2 | 0.22 | 3.04 | 4.53 | 2.97 | 8.91 | 1700 | 2200 |

| 225 | 56 | 2.1 | 338 | 768 | 23030/W33 | 3003130Y | 162 | 213 | 2 | 0.22 | 3.04 | 4.53 | 2.97 | 8.85 | 1700 | 2200 | |

| 225 | 75 | 2.1 | 564 | 1040 | 24030CC/W33 | - | 162 | 213 | 2 | 0.3 | 2.23 | 3.32 | 2.18 | 10.5 | 1300 | 1700 | |

| 250 | 80 | 2.1 | 725 | 1200 | 23130CA | - | 162 | 238 | 2 | 0.3 | 2.24 | 3.34 | 2.19 | 16 | 1400 | 1800 | |

| 250 | 100 | 2.1 | 890 | 1600 | 24130C | 4053730 | 162 | 238 | 2 | 0.38 | 1.77 | 2.64 | 1.73 | 20.4 | 1000 | 1400 | |

| 250 | 100 | 2.1 | 890 | 1600 | 24130C/W33 | 4053730Y | 162 | 238 | 2 | 0.38 | 1.77 | 2.64 | 1.73 | 20 | 1000 | 1400 | |

| 270 | 73 | 3 | 738 | 1100 | 22230C | 53530 | 164 | 256 | 2.5 | 0.25 | 2.69 | 4 | 2.63 | 18.9 | 1600 | 2000 | |

| 270 | 96 | 3 | 935 | 1520 | 23230C/W33 | 3053230Y | 164 | 256 | 2.5 | 0.34 | 1.96 | 2.93 | 1.92 | 24.3 | 1100 | 1500 | |

| 320 | 108 | 4 | 1270 | 1850 | 22330CA/W33 | 53630HY | 168 | 302 | 3 | 0.38 | 1.78 | 2.64 | 1.74 | 41.7 | 1000 | 1400 | |

| 160 | 240 | 60 | 2.1 | 376 | 825 | 23032 | 3003132 | 172 | 228 | 2 | 0.22 | 3.01 | 4.48 | 2.94 | 13.5 | 1700 | 2200 |

| 240 | 60 | 2.1 | 376 | 825 | 23032/W33 | 3003132Y | 172 | 228 | 2 | 0.22 | 3.01 | 4.48 | 2.94 | 13.4 | 1700 | 2200 | |

| 160 | 240 | 80 | 2.1 | 652 | 1230 | 24032C | 4053132 | 172 | 228 | 2 | 0.3 | 2.24 | 3.34 | 2.19 | 12.9 | 1100 | 1500 |

| 240 | 80 | 2.1 | 652 | 1230 | 24032C/W33 | 4053132Y | 172 | 228 | 2 | 0.3 | 2.24 | 3.34 | 2.19 | 12.8 | 1100 | 1500 | |

| 270 | 86 | 2.1 | 845 | 1370 | 23132CA | - | 172 | 258 | 2 | 0.3 | 2.22 | 3.3 | 2.17 | 20.5 | 950 | 1300 | |

| 270 | 109 | 2.1 | 1040 | 1880 | 24132C | 4053732 | 172 | 258 | 2 | 0.39 | 1.74 | 2.59 | 1.7 | 25.4 | 950 | 1300 | |

| 270 | 109 | 2.1 | 1040 | 1880 | 24132C/W33 | 4053732Y | 172 | 258 | 2 | 0.39 | 1.74 | 2.59 | 1.7 | 25 | 950 | 1300 | |

| 290 | 80 | 3 | 658 | 1140 | 22232 | 3532 | 174 | 276 | 2.5 | 0.28 | 2.4 | 3.57 | 2.35 | 22.2 | 1500 | 1900 | |

| 290 | 80 | 3 | 658 | 1140 | 22232/W33 | 3532Y | 174 | 276 | 2.5 | 0.28 | 2.4 | 3.57 | 2.35 | 22.1 | 1500 | 1900 | |

| 290 | 104 | 3 | 1030 | 1650 | 23232 | - | 174 | 276 | 2.5 | 0.38 | 1.79 | 2.66 | 1.75 | 31 | 1100 | 1500 | |

| 340 | 114 | 4 | 1170 | 1730 | 22332/W33 | 3632Y | 178 | 322 | 3 | 0.38 | 1.76 | 2.62 | 1.72 | 49.9 | 950 | 1300 | |

| 170 | 230 | 45 | 2 | 353 | 691 | 23934 | - | 180 | 220 | 2 | 0.18 | 3.78 | 5.63 | 3.7 | 5.53 | 1700 | 2200 |

| 260 | 67 | 2.1 | 450 | 1010 | 23034 | 3003134 | 180 | 248 | 2 | 0.23 | 2.9 | 4.31 | 2.83 | 14.7 | 1600 | 2000 | |

| 170 | 260 | 67 | 2.1 | 450 | 1010 | 23034/W33 | 3003134Y | 180 | 248 | 2 | 0.23 | 2.9 | 4.31 | 2.83 | 14.6 | 1600 | 2000 |

| 260 | 90 | 2.1 | 799 | 1460 | 24034CA | - | 182 | 248 | 2 | 0.32 | 2.11 | 3.15 | 2.07 | 17.5 | 1000 | 1400 | |

| 280 | 88 | 2.1 | 897 | 1500 | 23134CA | - | 182 | 268 | 2 | 0.31 | 2.16 | 3.22 | 2.11 | 21.5 | 1200 | 1600 | |

| 280 | 109 | 2.1 | 1070 | 1860 | 24134/W33 | - | 182 | 268 | 2 | 0.37 | 1.82 | 2.7 | 1.78 | 27 | 900 | 1200 | |

| 310 | 86 | 4 | 730 | 1300 | 22234 | 3534 | 188 | 292 | 3 | 0.29 | 2.29 | 3.41 | 2.24 | 27.6 | 1300 | 1700 | |

| 310 | 86 | 4 | 730 | 1300 | 22234/W33 | 3534Y | 188 | 292 | 3 | 0.29 | 2.29 | 3.41 | 2.24 | 27.2 | 1300 | 1700 | |

| 310 | 110 | 4 | 1160 | 1835 | 23234CA | 3053234H | 188 | 292 | 3 | 0.37 | 1.81 | 2.7 | 1.77 | 37.1 | 950 | 1300 | |

| 360 | 120 | 4 | 1200 | 2060 | 22334 | 3634 | 188 | 342 | 3 | 0.38 | 1.77 | 2.64 | 1.73 | 59.8 | 950 | 1300 | |

| 360 | 120 | 4 | 1200 | 2060 | 22334/W33 | 3634Y | 188 | 342 | 3 | 0.38 | 1.77 | 2.64 | 1.73 | 59.3 | 950 | 1300 | |

| 180 | 250 | 52 | 2 | 431 | 830 | 23936CA | - | 190 | 240 | 2 | 0.19 | 3.55 | 5.29 | 3.48 | 8.2 | 1700 | 2200 |

| Boundary dimensions | Basic load ratings | Part number | Installation | Constant | Axial | Mass | Limiting speeds | ||||||||||

| (mm) | |||||||||||||||||

| mm | kN | Current | Original | dbmin | Damin | ramax | e | Y2 | Y3 | Y0 | kg | r/min | |||||

| d | D | B | rmin | Cr | Cor | Grease | Oil | ||||||||||

| 180 | 280 | 74 | 2.1 | 550 | 1100 | 23036 | 3003136 | 192 | 268 | 2 | 0.26 | 2.61 | 3.88 | 2.55 | 19.5 | 1300 | 1600 |

| 280 | 100 | 2.1 | 930 | 1820 | 24036 | 4003136 | 192 | 268 | 2 | 0.32 | 2.12 | 3.15 | 2.07 | 22.5 | 950 | 1300 | |

| 280 | 100 | 2.1 | 930 | 1820 | 24036/W33 | 4003136Y | 192 | 268 | 2 | 0.32 | 2.12 | 3.15 | 2.07 | 22.3 | 950 | 1300 | |

| 300 | 96 | 3 | 695 | 1480 | 23136 | 3003736 | 194 | 286 | 2.5 | 0.33 | 2.04 | 3.04 | 2 | 27.1 | 1100 | 1500 | |

| 300 | 96 | 3 | 695 | 1480 | 23136/W33 | 3003736Y | 194 | 286 | 2.5 | 0.33 | 2.04 | 3.04 | 2 | 26.8 | 1100 | 1500 | |

| 300 | 96 | 3 | 695 | 1480 | 23136/C9 | 3003736U | 194 | 286 | 2.5 | 0.33 | 2.04 | 3.04 | 2 | 27.1 | 1100 | 1500 | |

| 300 | 96 | 3 | 695 | 1480 | 23136/W33YA2 | 3003736KY | 194 | 286 | 2.5 | 0.33 | 2.04 | 3.04 | 2 | 26.8 | 1100 | 1500 | |

| 300 | 96 | 3 | 695 | 1480 | 23136N | 3203736 | 194 | 286 | 2.5 | 0.33 | 2.04 | 3.04 | 2 | 26.4 | 1100 | 1500 | |

| 300 | 118 | 3 | 1220 | 2176 | 24136CA | - | 194 | 286 | 2.5 | 0.39 | 1.73 | 2.57 | 1.69 | 33.5 | 900 | 1200 | |

| 320 | 86 | 4 | 750 | 1370 | 22236 | 3536 | 198 | 302 | 3 | 0.28 | 2.37 | 3.53 | 2.32 | 28.6 | 1300 | 1700 | |

| 320 | 86 | 4 | 750 | 1370 | 22236/W33 | 3536Y | 198 | 302 | 3 | 0.28 | 2.37 | 3.53 | 2.32 | 28.3 | 1300 | 1700 | |

| 180 | 320 | 112 | 4 | 1280 | 2170 | 23236CA | 3053236H | 198 | 302 | 3 | 0.37 | 1.84 | 2.74 | 1.8 | 39.6 | 900 | 1200 |

| 320 | 112 | 4 | 1280 | 2170 | 23236CA/W33 | 3053236HY | 198 | 302 | 3 | 0.37 | 1.84 | 2.74 | 1.8 | 39.5 | 900 | 1200 | |

| 320 | 112 | 4 | 1280 | 2170 | 23236CA/W33YA2 | 3053236HKY | 198 | 302 | 3 | 0.37 | 1.84 | 2.74 | 1.8 | 39.4 | 900 | 1200 | |

| 380 | 126 | 4 | 1430 | 2210 | 22336 | 3636 | 198 | 362 | 3 | 0.36 | 1.89 | 2.81 | 1.84 | 80.7 | 900 | 1200 | |

| 380 | 126 | 4 | 1430 | 2210 | 22336/W33 | 3636Y | 198 | 362 | 3 | 0.36 | 1.89 | 2.81 | 1.84 | 79.9 | 900 | 1200 | |

| 190 | 260 | 52 | 2 | 414 | 800 | 23938CA | - | 200 | 250 | 2 | 0.18 | 3.69 | 5.5 | 3.61 | 8.4 | 1700 | 2200 |

| 280 | 67 | 2.5 | 542 | 978 | 2638 | 3738 | 13.7 | 1000 | 1400 | ||||||||

| 290 | 75 | 2.1 | 626 | 1230 | 23038 | 3003138 | 202 | 278 | 2 | 0.25 | 2.67 | 3.97 | 2.61 | 20.5 | 1300 | 1700 | |

| 290 | 75 | 2.1 | 626 | 1230 | 23038/W33 | 3003138Y | 202 | 278 | 2 | 0.25 | 2.67 | 3.97 | 2.61 | 20.3 | 1300 | 1700 | |

| 290 | 100 | 2.1 | 978 | 1800 | 24038CA | - | 202 | 278 | 2 | 0.31 | 2.2 | 3.27 | 2.15 | 24 | 950 | 1300 | |

| 320 | 104 | 3 | 1200 | 2080 | 23138CA | - | 204 | 306 | 2.5 | 0.34 | 1.96 | 2.92 | 1.92 | 34.5 | 1000 | 1400 | |

| Boundary dimensions | Basic load ratings | Part number | Installation | Constant | Axial | Mass | Limiting speeds | ||||||||||

| (mm) | |||||||||||||||||

| mm | kN | Current | Original | dbmin | Damin | ramax | e | Y2 | Y3 | Y0 | kg | r/min | |||||

| d | D | B | rmin | Cr | Cor | Grease | Oil | ||||||||||

| 190 | 320 | 128 | 3 | 1200 | 2100 | 24138CA/W33 | - | 204 | 306 | 2.5 | 0.39 | 1.74 | 2.58 | 1.7 | 42 | 850 | 1100 |

| 340 | 92 | 4 | 1070 | 1650 | 22238CA | 53538H | 208 | 322 | 3 | 0.29 | 2.29 | 3.41 | 2.24 | 36 | 1200 | 1600 | |

| 340 | 120 | 4 | 1410 | 2490 | 23238CA | 3053238H | 208 | 322 | 3 | 0.36 | 1.87 | 2.79 | 1.83 | 51 | 850 | 1100 | |

| 400 | 132 | 5 | 1400 | 2530 | 22338 | 3638 | 212 | 378 | 4 | 0.38 | 1.79 | 2.66 | 1.75 | 80.6 | 850 | 1100 | |

| 400 | 132 | 5 | 1400 | 2530 | 22338/W33 | 3638Y | 212 | 378 | 4 | 0.38 | 1.79 | 2.66 | 1.75 | 79.7 | 850 | 1100 | |

| 200 | 280 | 60 | 2.1 | 546 | 1040 | 23940CA | - | 212 | 268 | 2 | 0.2 | 3.44 | 5.13 | 3.37 | 11.5 | 1600 | 2000 |

| 310 | 82 | 2.1 | 655 | 1310 | 23040 | 3003140 | 212 | 298 | 2 | 0.26 | 2.62 | 3.9 | 2.56 | 26.2 | 1200 | 1600 | |

| 310 | 82 | 2.1 | 655 | 1310 | 23040/W33 | 3003140Y | 212 | 298 | 2 | 0.26 | 2.62 | 3.9 | 2.56 | 26 | 1200 | 1600 | |

| 310 | 109 | 2.1 | 1130 | 2120 | 24040CA/W33 | - | 212 | 298 | 2 | 0.33 | 2.03 | 3.02 | 1.98 | 30.5 | 900 | 1200 | |

| 340 | 112 | 3 | 930 | 2010 | 23140 | 3003740 | 214 | 326 | 2.5 | 0.34 | 1.97 | 2.94 | 1.93 | 50.9 | 950 | 1300 | |

| 200 | 340 | 112 | 3 | 930 | 2010 | 23140/W33 | 3003740Y | 214 | 326 | 2.5 | 0.34 | 1.97 | 2.94 | 1.93 | 50.5 | 950 | 1300 |

| 340 | 140 | 3 | 1530 | 2950 | 24140C | 4053740 | 214 | 326 | 2.5 | 0.38 | 1.75 | 2.61 | 1.72 | 52 | 800 | 1000 | |

| 340 | 140 | 3 | 1530 | 2950 | 24140C/W33 | 4053740Y | 214 | 326 | 2.5 | 0.38 | 1.75 | 2.61 | 1.72 | 51.9 | 800 | 1000 | |

| 360 | 98 | 4 | 940 | 1740 | 22240 | 3540 | 218 | 342 | 3 | 0.3 | 2.26 | 3.36 | 2.21 | 44.7 | 1100 | 1500 | |

| 360 | 98 | 4 | 940 | 1740 | 22240/W33 | 3540Y | 218 | 342 | 3 | 0.3 | 2.26 | 3.36 | 2.21 | 44.2 | 1100 | 1500 | |

| 360 | 128 | 4 | 1610 | 2700 | 23240/W33 | 3003240Y | 218 | 342 | 3 | 0.38 | 1.79 | 2.67 | 1.75 | 56.5 | 850 | 1100 | |

| 420 | 138 | 5 | 1530 | 2720 | 22340 | 3640 | 222 | 398 | 4 | 0.38 | 1.8 | 2.68 | 1.76 | 95.3 | 850 | 1100 | |

| 420 | 138 | 5 | 1530 | 2720 | 22340/W33 | 3640Y | 222 | 398 | 4 | 0.38 | 1.8 | 2.68 | 1.76 | 95 | 850 | 1100 | |

| 220 | 300 | 60 | 2.1 | 546 | 1080 | 23944CA | - | 232 | 288 | 2 | 0.18 | 3.7 | 5.5 | 3.61 | 13 | 1500 | 1900 |

| 320 | 76 | 3 | 758 | 1280 | 2644 | 3844 | 21.6 | 1000 | 1400 | ||||||||

| Boundary dimensions | Basic load ratings | Part number | Installation | Constant | Axial | Mass | Limiting speeds | ||||||||||

| (mm) | |||||||||||||||||

| mm | kN | Current | Original | dbmin | Damin | ramax | e | Y2 | Y3 | Y0 | kg | r/min | |||||

| d | D | B | rmin | Cr | Cor | Grease | Oil | ||||||||||

| 220 | 340 | 90 | 3 | 1050 | 1860 | 23044CA | - | 234 | 326 | 2.5 | 0.26 | 2.55 | 3.8 | 2.5 | 30.5 | 1100 | 1500 |

| 340 | 118 | 3 | 1360 | 2600 | 24044 | - | 234 | 326 | 2.6 | 0.33 | 2.07 | 3.08 | 2.02 | 39.5 | 850 | 1100 | |

| 370 | 120 | 4 | 1050 | 2350 | 23144 | 3003744 | 238 | 352 | 3 | 0.34 | 2 | 2.98 | 1.96 | 54 | 900 | 1200 | |

| 370 | 120 | 4 | 1050 | 2350 | 23144/W33 | 3003744Y | 238 | 352 | 3 | 0.34 | 2 | 2.98 | 1.96 | 53.5 | 900 | 1200 | |

| 370 | 150 | 4 | 1840 | 3350 | 24144CA | - | 238 | 352 | 3 | 0.38 | 1.77 | 2.63 | 1.73 | 65 | 750 | 950 | |

| 400 | 108 | 4 | 1200 | 2220 | 22244 | 3544 | 238 | 382 | 3 | 0.28 | 2.4 | 3.57 | 2.34 | 57.6 | 950 | 1300 | |

| 400 | 108 | 4 | 1200 | 2220 | 22244/W33 | 3544Y | 238 | 382 | 3 | 0.28 | 2.4 | 3.57 | 2.34 | 57.1 | 950 | 1300 | |

| 400 | 144 | 4 | 2070 | 3620 | 23244 | 3003244 | 238 | 382 | 3 | 0.39 | 1.71 | 2.55 | 1.68 | 94.6 | 750 | 950 | |

| 400 | 144 | 4 | 2070 | 3620 | 23244/W33 | 3003244Y | 238 | 382 | 3 | 0.39 | 1.71 | 2.55 | 1.68 | 94.2 | 750 | 950 | |

| 460 | 145 | 5 | 1700 | 3200 | 22344 | 3644 | 242 | 438 | 4 | 0.34 | 2 | 2.99 | 1.96 | 130 | 750 | 950 | |

| 220 | 460 | 145 | 5 | 1700 | 3200 | 22344/W33 | 3644Y | 242 | 438 | 4 | 0.34 | 2 | 2.99 | 1.96 | 129 | 750 | 950 |

| 230 | 420 | 114 | 4 | 1600 | 2600 | 22246 | 3546 | 69.5 | 750 | 950 | |||||||

| 240 | 320 | 60 | 2.1 | 564 | 1160 | 23948CA | - | 252 | 308 | 2 | 0.17 | 3.95 | 5.88 | 3.86 | 14 | 1300 | 1700 |

| 360 | 92 | 3 | 820 | 2060 | 23048 | 3003148 | 254 | 346 | 2.5 | 0.22 | 2.71 | 4.04 | 2.65 | 37.6 | 1000 | 1400 | |

| 360 | 92 | 3 | 820 | 2060 | 23048/W33 | 3003148Y | 254 | 346 | 2.5 | 0.22 | 2.71 | 4.04 | 2.65 | 37.4 | 1000 | 1400 | |

| 360 | 118 | 3 | 1380 | 2700 | 24048CA/W33 | - | 254 | 346 | 2.5 | 0.31 | 2.2 | 3.28 | 2.15 | 41.7 | 800 | 1000 | |

| 400 | 128 | 4 | 1200 | 2850 | 23148 | 3003748 | 258 | 382 | 3 | 0.33 | 2.05 | 3.05 | 2 | 77.2 | 850 | 1100 | |

| 400 | 128 | 4 | 1200 | 2850 | 23148/W33 | 3003748Y | 258 | 382 | 3 | 0.33 | 2.05 | 3.05 | 2 | 75.2 | 850 | 1100 | |

| 400 | 160 | 4 | 2100 | 3980 | 24148/W33 | 4003748Y | 258 | 382 | 3 | 0.39 | 1.71 | 2.55 | 1.67 | 81.6 | 670 | 850 | |

| 440 | 120 | 4 | 1870 | 2890 | 22248 | 3548 | 258 | 422 | 3 | 0.29 | 2.35 | 3.5 | 2.3 | 85 | 900 | 1200 | |

| Boundary dimensions | Basic load ratings | Part number | Installation | Constant | Axial | Mass | Limiting speeds | ||||||||||

| (mm) | |||||||||||||||||

| mm | kN | Current | Original | dbmin | Damin | ramax | e | Y2 | Y3 | Y0 | kg | r/min | |||||

| d | D | B | rmin | Cr | Cor | Grease | Oil | ||||||||||

| 240 | 440 | 160 | 4 | 2490 | 4490 | 23248 | 3003248 | 258 | 422 | 3 | 0.39 | 1.73 | 2.57 | 1.69 | 128 | 670 | 850 |

| 440 | 160 | 4 | 2490 | 4490 | 23248/W33 | 3003248Y | 258 | 422 | 3 | 0.39 | 1.73 | 2.57 | 1.69 | 127 | 670 | 850 | |

| 500 | 155 | 5 | 1780 | 3250 | 22348 | 3648 | 262 | 478 | 4 | 0.35 | 1.94 | 2.89 | 1.9 | 154 | 670 | 850 | |

| 500 | 155 | 5 | 1780 | 3250 | 22348/W33 | 3648Y | 262 | 478 | 4 | 0.35 | 1.94 | 2.89 | 1.9 | 153 | 670 | 850 | |

| 250 | 365 | 87 | 3 | 950 | 1650 | 2650 | 3750 | 32.2 | 880 | 1100 | |||||||

| 260 | 360 | 75 | 2.1 | 886 | 1700 | 23952CA/W33 | - | 272 | 348 | 2 | 0.19 | 3.54 | 5.27 | 3.46 | 22.5 | 1100 | 1500 |

| 400 | 104 | 4 | 1000 | 2450 | 23052 | 3003152 | 278 | 382 | 3 | 0.25 | 2.65 | 3.95 | 2.59 | 51.5 | 900 | 1200 | |

| 400 | 104 | 4 | 1000 | 2450 | 23052/W33 | 3003152Y | 278 | 382 | 3 | 0.25 | 2.65 | 3.95 | 2.59 | 51.2 | 900 | 1200 | |

| 400 | 140 | 4 | 1690 | 3260 | 24052CA/W33 | - | 278 | 382 | 3 | 0.33 | 2.04 | 3.03 | 1.99 | 64.4 | 700 | 900 | |

| 440 | 144 | 4 | 1450 | 3320 | 23152 | 3003752 | 278 | 422 | 3 | 0.33 | 2.03 | 3.02 | 1.98 | 96 | 800 | 1000 | |

| 440 | 180 | 4 | 2660 | 5180 | 24152C/W33 | 4053752Y | 278 | 422 | 3 | 0.42 | 1.62 | 2.41 | 1.58 | 113 | 600 | 750 | |

| 480 | 130 | 5 | 2160 | 3400 | 22252CA | 53552H | 282 | 458 | 4 | 0.28 | 2.4 | 3.57 | 2.35 | 105 | 850 | 1100 | |

| 480 | 174 | 5 | 2800 | 4550 | 23252C/W33 | 3053252Y | 282 | 458 | 4 | 0.4 | 1.69 | 2.51 | 1.65 | 140 | 630 | 800 | |

| 480 | 174 | 5 | 2800 | 4550 | 23252CA | 3053252H | 282 | 458 | 4 | 0.4 | 1.69 | 2.51 | 1.65 | 151 | 630 | 800 | |

| 480 | 174 | 5 | 2800 | 4550 | 23252CA/W33 | 3053252HY | 282 | 458 | 4 | 0.4 | 1.69 | 2.51 | 1.65 | 151 | 630 | 800 | |

| 490 | 153 | 4 | 2070 | 3650 | 2652 | 3752 | 140 | 760 | 1050 | ||||||||

| 540 | 165 | 6 | 2250 | 4190 | 22352 | 3652 | 288 | 512 | 5 | 0.35 | 1.94 | 2.89 | 1.9 | 193 | 630 | 800 | |

| 260 | 540 | 165 | 6 | 2250 | 4190 | 22352/W33 | 3652Y | 288 | 512 | 5 | 0.35 | 1.94 | 2.89 | 1.9 | 192 | 630 | 800 |

| 280 | 380 | 75 | 2.1 | 800 | 1500 | 23956CA/W33 | 3113956Y | 292 | 368 | 2 | 0.18 | 3.74 | 5.57 | 3.66 | 24.5 | 900 | 1200 |

| 420 | 106 | 4 | 1100 | 2680 | 23056 | 3003156 | 298 | 402 | 3 | 0.25 | 2.74 | 4.08 | 2.68 | 62 | 850 | 1100 | |

| 420 | 106 | 4 | 1100 | 2680 | 23056/W33 | 3003156Y | 298 | 402 | 3 | 0.25 | 2.74 | 4.08 | 2.68 | 61.5 | 850 | 1100 | |

| 420 | 140 | 4 | 1200 | 2800 | 24056CA/W33 | - | 298 | 402 | 3 | 0.31 | 2.21 | 3.29 | 2.16 | 67.2 | 800 | 1000 | |

| Boundary dimensions | Basic load ratings | Part number | Installation | Constant | Axial | Mass | Limiting speeds | ||||||||||

| (mm) | |||||||||||||||||

| mm | kN | Current | Original | dbmin | Damin | ramax | e | Y2 | Y3 | Y0 | kg | r/min | |||||

| d | D | B | rmin | Cr | Cor | Grease | Oil | ||||||||||

| 280 | 460 | 146 | 5 | 1590 | 3630 | 23156 | 3003756 | 302 | 438 | 4 | 0.33 | 2.04 | 3.03 | 1.99 | 95.5 | 750 | 950 |

| 460 | 180 | 5 | 2000 | 4100 | 24156CA/W33 | - | 302 | 438 | 4 | 0.4 | 1.69 | 2.51 | 1.65 | 119 | 750 | 950 | |

| 500 | 130 | 5 | 1690 | 3380 | 22256 | 3556 | 302 | 478 | 4 | 0.28 | 2.42 | 3.6 | 2.37 | 126 | 800 | 1000 | |

| 500 | 130 | 5 | 1690 | 3380 | 22256/W33 | 3556Y | 302 | 478 | 4 | 0.28 | 2.42 | 3.6 | 2.37 | 124 | 800 | 1000 | |

| 500 | 176 | 5 | 2880 | 4900 | 23256 | 3003256 | 302 | 478 | 4 | 0.37 | 1.83 | 2.72 | 1.79 | 153 | 600 | 750 | |

| 500 | 176 | 5 | 2880 | 4900 | 23256/W33 | 3003256Y | 302 | 478 | 4 | 0.37 | 1.83 | 2.72 | 1.79 | 152 | 600 | 750 | |

| 580 | 175 | 6 | 3500 | 5150 | 22356 | 3656 | 308 | 552 | 5 | 0.34 | 1.98 | 2.95 | 1.93 | 238 | 600 | 750 | |

| 580 | 175 | 6 | 3500 | 5150 | 22356/W33 | 3656Y | 308 | 552 | 5 | 0.34 | 1.98 | 2.95 | 1.93 | 238 | 600 | 750 | |

| 300 | 420 | 90 | 3 | 1200 | 2500 | 23960CA | - | 314 | 406 | 2.5 | 0.2 | 3.42 | 5.09 | 3.34 | 40.5 | 950 | 1300 |

| 460 | 118 | 4 | 1260 | 3070 | 23060 | 3003160 | 318 | 442 | 3 | 0.25 | 2.69 | 4 | 2.63 | 75.2 | 800 | 1000 | |

| 460 | 118 | 4 | 1260 | 3070 | 23060/W33 | 3003160Y | 318 | 442 | 3 | 0.25 | 2.69 | 4 | 2.63 | 74.6 | 800 | 1000 | |

| 300 | 460 | 160 | 4 | 2360 | 5010 | 24060C/W33 | 4053160Y | 318 | 442 | 3 | 0.33 | 2.04 | 3.04 | 2 | 101 | 600 | 750 |

| 500 | 160 | 5 | 2670 | 4800 | 23160 | 3003760 | 322 | 478 | 4 | 0.33 | 2.02 | 3.01 | 1.98 | 134 | 670 | 850 | |

| 500 | 160 | 5 | 2670 | 4800 | 23160/W33 | 3003760Y | 322 | 478 | 4 | 0.33 | 2.02 | 3.01 | 1.98 | 133 | 670 | 850 | |

| 500 | 200 | 5 | 3100 | 5800 | 24160C | 4053760 | 322 | 478 | 4 | 0.39 | 1.72 | 2.56 | 1.68 | 160 | 530 | 670 | |

| 500 | 200 | 5 | 3100 | 580 | 24160C/W33 | 4053760Y | 322 | 478 | 4 | 0.39 | 1.72 | 2.56 | 1.68 | 159 | 530 | 670 | |

| 540 | 140 | 5 | 2610 | 4250 | 22260 | 3560 | 322 | 518 | 4 | 0.27 | 2.48 | 3.69 | 2.43 | 143 | 750 | 950 | |

| 540 | 192 | 5 | 3430 | 5910 | 23260 | - | 322 | 518 | 4 | 0.37 | 1.83 | 2.72 | 1.79 | 197 | 630 | 800 | |

| 620 | 185 | 7.5 | 3910 | 5430 | 22360 | - | 336 | 584 | 6 | 0.32 | 2.09 | 3.1 | 2.04 | 289 | 480 | 600 | |

| 320 | 440 | 90 | 3 | 1060 | 2390 | 23964K | 3113964 | 334 | 426 | 2.5 | 0.19 | 3.61 | 5.38 | 3.53 | 45.1 | 900 | 1200 |

| 480 | 121 | 4 | 1380 | 3260 | 23064 | 3003164 | 338 | 462 | 3 | 0.24 | 2.76 | 4.11 | 2.7 | 81.5 | 800 | 1000 | |

| 480 | 121 | 4 | 1380 | 3260 | 23064/W33 | 3003164Y | 338 | 462 | 3 | 0.24 | 2.76 | 4.11 | 2.7 | 80.9 | 800 | 1000 | |

| Boundary dimensions | Basic load ratings | Part number | Installation | Constant | Axial | Mass | Limiting speeds | ||||||||||

| (mm) | |||||||||||||||||

| mm | kN | Current | Original | dbmin | Damin | ramax | e | Y2 | Y3 | Y0 | kg | r/min | |||||

| d | D | B | rmin | Cr | Cor | Grease | Oil | ||||||||||

| 320 | 480 | 160 | 4 | 2440 | 5050 | 24064 | 4003164 | 338 | 462 | 3 | 0.32 | 2.13 | 3.17 | 2.08 | 103 | 560 | 700 |

| 540 | 176 | 5 | 3280 | 6000 | 23164CA | - | 342 | 518 | 4 | 0.33 | 2.04 | 3.04 | 2 | 165 | 630 | 800 | |

| 540 | 218 | 5 | 3550 | 6650 | 24164 | 4003764 | 342 | 518 | 4 | 0.41 | 1.66 | 2.47 | 1.62 | 252 | 480 | 600 | |

| 540 | 218 | 5 | 3550 | 6650 | 24164/W33 | 4003764Y | 342 | 518 | 4 | 0.41 | 1.66 | 2.47 | 1.62 | 251 | 480 | 600 | |

| 580 | 150 | 5 | 2730 | 4540 | 22264 | - | 342 | 558 | 4 | 0.28 | 2.41 | 3.59 | 2.35 | 175 | 560 | 700 | |

| 580 | 208 | 5 | 3900 | 6900 | 23264 | 3003264 | 342 | 558 | 4 | 0.38 | 1.76 | 2.62 | 1.72 | 260 | 500 | 630 | |

| 580 | 208 | 5 | 3900 | 6900 | 23264/W33 | 3003264Y | 342 | 558 | 4 | 0.38 | 1.76 | 2.62 | 1.72 | 259 | 500 | 630 | |

| 340 | 460 | 90 | 3 | 1330 | 2840 | 23968 | 3003968 | 354 | 446 | 2.5 | 0.18 | 3.82 | 5.69 | 3.74 | 50.5 | 900 | 1200 |

| 520 | 133 | 5 | 1580 | 3810 | 23068 | 3003168 | 362 | 498 | 4 | 0.25 | 2.69 | 4 | 2.63 | 109 | 700 | 900 | |

| 520 | 133 | 5 | 1580 | 3810 | 23068/W33 | 3003168Y | 362 | 498 | 4 | 0.25 | 2.69 | 4 | 2.63 | 109 | 700 | 900 | |

| 520 | 180 | 5 | 2920 | 6050 | 24068/W33 | 4003168Y | 362 | 498 | 4 | 0.33 | 2.06 | 3.06 | 2.01 | 160 | 530 | 670 | |

| 340 | 580 | 190 | 5 | 3470 | 6240 | 23168/W33 | 3003768Y | 362 | 558 | 4 | 0.34 | 1.97 | 2.93 | 1.93 | 207 | 500 | 630 |

| 580 | 243 | 5 | 4660 | 8650 | 24168CA | - | 362 | 558 | 4 | 0.41 | 1.66 | 2.47 | 1.62 | 280 | 450 | 560 | |

| 620 | 165 | 6 | 3550 | 5430 | 22268 | - | 368 | 592 | 5 | 0.28 | 2.43 | 3.61 | 2.37 | 221 | 560 | 700 | |

| 620 | 224 | 6 | 4090 | 7560 | 23268 | - | 368 | 592 | 5 | 0.38 | 1.77 | 2.63 | 1.73 | 306 | 500 | 630 | |

| 360 | 480 | 90 | 3 | 1130 | 2710 | 23972 | 3003972 | 374 | 466 | 2.5 | 0.17 | 3.95 | 5.88 | 3.86 | 49.1 | 850 | 1100 |

| 540 | 134 | 5 | 1750 | 4180 | 23072 | 3003172 | 382 | 518 | 4 | 0.24 | 2.76 | 4.11 | 2.7 | 114 | 670 | 850 | |

| 540 | 134 | 5 | 1750 | 4180 | 23072/W33 | 3003172Y | 382 | 518 | 4 | 0.24 | 2.76 | 4.11 | 2.7 | 114 | 670 | 850 | |

| 540 | 180 | 5 | 2930 | 6100 | 24072C | 4053172 | 382 | 518 | 4 | 0.32 | 2.13 | 3.17 | 2.08 | 149 | 500 | 630 | |

| 540 | 180 | 5 | 2930 | 6100 | 24072C/W33 | 4053172Y | 382 | 518 | 4 | 0.32 | 2.13 | 3.17 | 2.08 | 148 | 500 | 630 | |

| 600 | 192 | 5 | 3800 | 7100 | 23172 | 3003772 | 382 | 578 | 4 | 0.33 | 2.07 | 3.09 | 2.03 | 222 | 560 | 700 | |

| 600 | 192 | 5 | 3800 | 7100 | 23172/W33 | 3003772Y | 382 | 578 | 4 | 0.33 | 2.07 | 3.09 | 2.03 | 221 | 560 | 700 | |

| Boundary dimensions | Basic load ratings | Part number | Installation | Constant | Axial | Mass | Limiting speeds | ||||||||||

| (mm) | |||||||||||||||||

| mm | kN | Current | Original | dbmin | Damin | ramax | e | Y2 | Y3 | Y0 | kg | r/min | |||||

| d | D | B | rmin | Cr | Cor | Grease | Oil | ||||||||||

| 360 | 600 | 243 | 5 | 4300 | 8000 | 24172 | 4003772 | 382 | 578 | 4 | 0.39 | 1.74 | 2.59 | 1.7 | 333 | 430 | 530 |

| 600 | 243 | 5 | 4300 | 8000 | 24172CA/W33 | 4003772HY | 382 | 578 | 4 | 0.39 | 1.74 | 2.59 | 1.7 | 338 | 430 | 530 | |

| 650 | 170 | 6 | 3770 | 5830 | 22272 | - | 388 | 622 | 5 | 0.27 | 2.47 | 3.68 | 2.42 | 248 | 340 | 430 | |

| 650 | 232 | 6 | 4850 | 8810 | 23272 | - | 388 | 622 | 5 | 0.37 | 1.83 | 2.72 | 1.79 | 346 | 340 | 430 | |

| 750 | 224 | 7.5 | 4180 | 7500 | 22372 | 3672 | 494 | 280 | 360 | ||||||||

| 380 | 520 | 106 | 4 | 1870 | 4100 | 23976 | 3003976 | 398 | 502 | 3 | 0.19 | 3.62 | 5.39 | 3.54 | 73.5 | 800 | 1000 |

| 560 | 135 | 5 | 2500 | 5100 | 23076 | 3003176 | 402 | 538 | 4 | 0.24 | 2.79 | 4.16 | 2.73 | 122 | 630 | 800 | |

| 560 | 180 | 5 | 3160 | 6800 | 24076CA | - | 402 | 538 | 4 | 0.3 | 2.22 | 3.3 | 2.17 | 150 | 480 | 600 | |

| 620 | 194 | 5 | 2680 | 6240 | 23176 | 3003776 | 402 | 598 | 4 | 0.31 | 2.18 | 3.24 | 2.13 | 244 | 400 | 500 | |

| 620 | 194 | 5 | 2680 | 6240 | 23176/W33 | 3003776Y | 402 | 598 | 4 | 0.31 | 2.18 | 3.24 | 2.13 | 243 | 400 | 500 | |

| 620 | 243 | 5 | 5060 | 9800 | 24176CA | - | 402 | 598 | 4 | 0.38 | 1.78 | 2.65 | 1.74 | 300 | 340 | 430 | |

| 380 | 680 | 240 | 6 | 5200 | 9500 | 23276 | - | 408 | 652 | 5 | 0.36 | 1.85 | 2.76 | 1.81 | 386 | 340 | 430 |

| 400 | 540 | 106 | 4 | 1730 | 3900 | 23980CA | - | 418 | 522 | 3 | 0.18 | 3.76 | 5.59 | 3.67 | 71 | 750 | 950 |

| 590 | 142 | 6 | 2290 | 4420 | 2680 | 3880 | - | - | - | - | - | - | - | 145 | 340 | 530 | |

| 600 | 148 | 5 | 2970 | 5900 | 23080 | 3003180 | 422 | 578 | 4 | 0.24 | 2.84 | 4.23 | 2.78 | 165 | 600 | 750 | |

| 600 | 148 | 5 | 2970 | 5900 | 23080/W33 | 3003180Y | 422 | 578 | 4 | 0.24 | 2.84 | 4.23 | 2.78 | 165 | 600 | 750 | |

| 600 | 200 | 5 | 3620 | 7800 | 24080CA | - | 422 | 578 | 4 | 0.32 | 2.09 | 3.12 | 2.05 | 205 | 450 | 560 | |

| 650 | 200 | 6 | 4150 | 7900 | 23180 | 3003780 | 428 | 622 | 5 | 0.31 | 2.19 | 3.25 | 2.14 | 239 | 380 | 480 | |

| 650 | 200 | 6 | 4150 | 7900 | 23180/W33 | 3003780Y | 428 | 622 | 5 | 0.31 | 2.19 | 3.25 | 2.14 | 238 | 380 | 480 | |

| 650 | 250 | 6 | 4700 | 9310 | 24180 | - | 428 | 622 | 5 | 0.37 | 1.82 | 2.7 | 1.78 | 326 | 320 | 400 | |

| 720 | 256 | 6 | 5800 | 10400 | 23280 | 3003280 | 428 | 692 | 5 | 0.37 | 1.8 | 2.69 | 1.76 | 530 | 340 | 430 | |

| 720 | 256 | 6 | 5800 | 10400 | 23280/W33 | 3003280Y | 428 | 692 | 5 | 0.37 | 1.8 | 2.69 | 1.76 | 530 | 340 | 430 | |

| Boundary dimensions | Basic load ratings | Part number | Installation | Constant | Axial | Mass | Limiting speeds | ||||||||||

| (mm) | |||||||||||||||||

| mm | kN | Current | Original | dbmin | Damin | ramax | e | Y2 | Y3 | Y0 | kg | r/min | |||||

| d | D | B | rmin | Cr | Cor | Grease | Oil | ||||||||||

| 400 | 820 | 243 | 7.5 | 4650 | 8960 | 22280 | 3680 | 432 | 788 | 6 | 0.37 | 1.8 | 2.7 | 1.8 | 650 | 240 | 320 |

| 420 | 520 | 75 | 2.1 | 1000 | 2500 | 23884/W33 | - | 34.5 | 630 | 800 | |||||||

| 560 | 106 | 4 | 1810 | 3750 | 23984/W33 | 3003984Y | 438 | 542 | 3 | 0.17 | 3.91 | 5.82 | 3.82 | 70.6 | 700 | 900 | |

| 620 | 150 | 5 | 2740 | 5580 | 23084 | 3003184 | 442 | 598 | 4 | 0.23 | 2.9 | 4.31 | 2.83 | 159 | 450 | 560 | |

| 620 | 150 | 5 | 2740 | 5580 | 23084/W33 | 3003184Y | 442 | 598 | 4 | 0.23 | 2.9 | 4.31 | 2.83 | 158 | 450 | 560 | |

| 620 | 200 | 5 | 3740 | 8150 | 24084CA | - | 442 | 598 | 4 | 0.3 | 2.23 | 3.32 | 2.18 | 210 | 380 | 480 | |

| 700 | 224 | 6 | 5000 | 9400 | 23184/W33 | 3003784Y | 448 | 672 | 5 | 0.33 | 2.03 | 3.02 | 1.98 | 402 | 360 | 450 | |

| 700 | 280 | 6 | 9330 | 12500 | 24184CA | - | 448 | 672 | 5 | 0.4 | 1.71 | 2.54 | 1.67 | 445 | 300 | 380 | |

| 760 | 272 | 7.5 | 6450 | 11700 | 23284CA | 3053284H | 456 | 724 | 6 | 0.37 | 1.84 | 2.74 | 1.8 | 659 | 320 | 400 | |

| 440 | 600 | 118 | 4 | 2150 | 4650 | 23988CA/W33 | - | 458 | 582 | 3 | 0.18 | 3.75 | 5.58 | 3.66 | 90.5 | 670 | 850 |

| 650 | 157 | 6 | 2710 | 5600 | 23088 | 3003188 | 468 | 622 | 5 | 0.24 | 2.76 | 4.11 | 2.7 | 192 | 430 | 530 | |

| 440 | 650 | 157 | 6 | 2710 | 5600 | 23088/W33 | 3003188Y | 468 | 622 | 5 | 0.24 | 2.76 | 4.11 | 2.7 | 191 | 430 | 530 |

| 650 | 212 | 6 | 4080 | 8800 | 24088CA | - | 468 | 622 | 5 | 0.29 | 2.35 | 3.5 | 2.3 | 245 | 360 | 450 | |

| 720 | 226 | 6 | 5300 | 10300 | 23188 | 3003788 | 468 | 692 | 5 | 0.33 | 2.08 | 3.09 | 2.03 | 420 | 340 | 430 | |

| 720 | 226 | 6 | 5300 | 10300 | 23188/W33 | 3003788Y | 468 | 692 | 5 | 0.33 | 2.08 | 3.09 | 2.03 | 419 | 340 | 430 | |

| 720 | 280 | 6 | 6560 | 13200 | 24188CA | - | 468 | 692 | 5 | 0.38 | 1.76 | 2.62 | 1.72 | 460 | 280 | 360 | |

| 790 | 280 | 7.5 | 6860 | 12300 | 23288 | - | 476 | 754 | 6 | 0.36 | 1.86 | 2.77 | 1.82 | 613 | 280 | 360 | |

| 460 | 620 | 118 | 4 | 2190 | 5000 | 23992CA | - | 478 | 602 | 3 | 0.17 | 3.89 | 5.79 | 3.8 | 105 | 430 | 530 |

| 680 | 163 | 6 | 2460 | 6670 | 23092 | 3003192 | 488 | 652 | 5 | 0.23 | 2.92 | 4.34 | 2.85 | 223 | 400 | 500 | |

| 680 | 163 | 6 | 2460 | 6670 | 23092/W33 | 3003192Y | 488 | 652 | 5 | 0.23 | 2.92 | 4.34 | 2.85 | 220 | 400 | 500 | |

| 680 | 218 | 6 | 4370 | 9500 | 24092CA | - | 488 | 652 | 5 | 0.3 | 2.23 | 3.32 | 2.18 | 275 | 340 | 430 | |

| 760 | 240 | 7.5 | 5640 | 10800 | 23192CA | - | 496 | 724 | 6 | 0.33 | 2.07 | 3.09 | 2.03 | 440 | 320 | 400 | |

| Boundary dimensions | Basic load ratings | Part number | Installation | Constant | Axial | Mass | Limiting speeds | ||||||||||

| (mm) | |||||||||||||||||

| mm | kN | Current | Original | dbmin | Damin | ramax | e | Y2 | Y3 | Y0 | kg | r/min | |||||

| d | D | B | rmin | Cr | Cor | Grease | Oil | ||||||||||

| 460 | 760 | 300 | 7.5 | 7250 | 14600 | 24192CA | - | 496 | 724 | 6 | 0.35 | 1.95 | 2.9 | 1.91 | 560 | 260 | 340 |

| 830 | 296 | 7.5 | 7610 | 13700 | 23292 | - | 496 | 794 | 6 | 0.36 | 1.85 | 2.76 | 1.81 | 720 | 240 | 320 | |

| 480 | 650 | 128 | 5 | 2060 | 5000 | 23996 | 3003996 | 502 | 628 | 4 | 0.18 | 3.75 | 5.59 | 3.67 | 162 | 400 | 500 |

| 650 | 128 | 5 | 2060 | 5000 | 23996/W33 | 3003996Y | 502 | 628 | 4 | 0.18 | 3.75 | 5.59 | 3.67 | 161 | 400 | 500 | |

| 700 | 165 | 6 | 2500 | 6440 | 23096 | 3003196 | 508 | 672 | 5 | 0.22 | 3.01 | 4.47 | 2.94 | 231 | 380 | 480 | |

| 700 | 218 | 6 | 4420 | 9650 | 24096 | - | 508 | 672 | 5 | 0.29 | 2.32 | 3.45 | 2.26 | 287 | 340 | 430 | |

| 790 | 248 | 7.5 | 5200 | 10700 | 23196/W33 | 3003796Y | 516 | 754 | 6 | 0.32 | 2.09 | 3.12 | 2.05 | 486 | 300 | 380 | |

| 790 | 308 | 7.5 | 7710 | 15600 | 24196CA | - | 516 | 754 | 6 | 0.39 | 1.74 | 2.59 | 1.7 | 605 | 240 | 320 | |

| 870 | 310 | 7.5 | 7850 | 14400 | 23296 | 3003296 | 516 | 834 | 6 | 0.36 | 1.85 | 2.75 | 1.81 | 837 | 260 | 340 | |

| 500 | 670 | 128 | 5 | 2100 | 5250 | 239/500 | 30039/500 | 522 | 648 | 4 | 0.17 | 3.87 | 5.76 | 3.79 | 135 | 400 | 500 |

| 500 | 720 | 167 | 6 | 2700 | 7180 | 230/500 | 30031/500 | 528 | 692 | 5 | 0.23 | 2.94 | 4.37 | 2.87 | 238 | 380 | 480 |

| 720 | 167 | 6 | 2700 | 7180 | 230/500/W33 | 30031/500Y | 528 | 692 | 5 | 0.23 | 2.94 | 4.37 | 2.87 | 238 | 380 | 480 | |

| 720 | 218 | 6 | 4600 | 10400 | 240/500CA | - | 528 | 692 | 5 | 0.28 | 2.39 | 3.56 | 2.34 | 295 | 320 | 400 | |

| 830 | 264 | 7.5 | 6730 | 12900 | 231/500CA | - | 536 | 794 | 6 | 0.33 | 2.05 | 3.05 | 2 | 580 | 280 | 360 | |

| 830 | 325 | 7.5 | 8630 | 17000 | 241/500CA | - | 536 | 794 | 6 | 0.36 | 1.85 | 2.76 | 1.81 | 745 | 220 | 300 | |

| 920 | 336 | 7.5 | 8430 | 15800 | 232/500/W33 | 30032/500Y | 536 | 884 | 6 | 0.39 | 1.74 | 2.59 | 1.7 | 1020 | 240 | 320 | |

| 530 | 710 | 136 | 5 | 2820 | 6700 | 239/530CA | - | 575 | 674 | 4 | 0.17 | 6 | 4 | 3.9 | 155 | 360 | 450 |

| 780 | 185 | 6 | 3180 | 8310 | 230/530 | 30031/530 | 581 | 736 | 5 | 0.22 | 4.6 | 3.1 | 3 | 313 | 340 | 430 | |

| 780 | 185 | 6 | 3180 | 8310 | 230/530/W33 | 30031/530Y | 581 | 736 | 5 | 0.22 | 4.6 | 3.1 | 3 | 312 | 340 | 430 | |

| 780 | 250 | 6 | 5640 | 12700 | 240/530CA | - | 581 | 736 | 5 | 0.31 | 3.3 | 2.2 | 2.2 | 410 | 280 | 360 | |

| 870 | 272 | 7.5 | 7130 | 14000 | 231/530CA | - | 589 | 817 | 6 | 0.3 | 3.3 | 2.2 | 2.2 | 645 | 260 | 340 | |

| Boundary dimensions | Basic load ratings | Part number | Installation | Constant | Axial | Mass | Limiting speeds | ||||||||||

| (mm) | |||||||||||||||||

| mm | kN | Current | Original | dbmin | Damin | ramax | e | Y2 | Y3 | Y0 | kg | r/min | |||||

| d | D | B | rmin | Cr | Cor | Grease | Oil | ||||||||||

| 530 | 870 | 335 | 7.5 | 9200 | 19000 | 241/530CA | - | 589 | 817 | 6 | 0.38 | 2.6 | 1.8 | 1.7 | 830 | 200 | 280 |

| 980 | 355 | 9.5 | 10100 | 18800 | 232/530CA | - | 597 | 917 | 8 | 0.38 | 2.7 | 1.8 | 1.7 | 1170 | 190 | 260 | |

| 560 | 750 | 140 | 5 | 3050 | 7200 | 239/560CA | - | 606 | 713 | 4 | 0.16 | 6.1 | 4.1 | 4 | 175 | 340 | 430 |

| 820 | 195 | 6 | 3490 | 9950 | 230/560 | 30031/560 | 612 | 776 | 5 | 0.22 | 4.5 | 3 | 2.9 | 367 | 320 | 400 | |

| 820 | 195 | 6 | 3490 | 9950 | 230/560/W33 | 30031/560Y | 612 | 776 | 5 | 0.22 | 4.5 | 3 | 2.9 | 365 | 320 | 400 | |

| 820 | 258 | 6 | 6210 | 14000 | 240/560CA | - | 612 | 776 | 5 | 0.3 | 3.3 | 2.2 | 2.2 | 465 | 260 | 340 | |

| 920 | 280 | 7.5 | 7100 | 14800 | 231/560/W33 | 30037/560Y | 620 | 866 | 6 | 0.3 | 3.4 | 2.3 | 2.2 | 757 | 240 | 320 | |

| 920 | 355 | 7.5 | 10500 | 21600 | 241/560CA | - | 620 | 866 | 6 | 0.39 | 2.6 | 1.8 | 1.7 | 985 | 190 | 260 | |

| 1030 | 365 | 9.5 | 10900 | 20500 | 232/560CA | - | 629 | 966 | 8 | 0.36 | 2.8 | 1.9 | 1.8 | 1320 | 170 | 220 | |

| 600 | 800 | 150 | 5 | 3450 | 8300 | 239/600CA | - | 647 | 762 | 4 | 0.17 | 5.9 | 3.9 | 3.9 | 220 | 320 | 400 |

| 870 | 200 | 6 | 3760 | 10400 | 230/600 | 30031/600 | 654 | 825 | 5 | 0.21 | 4.8 | 3.3 | 3.2 | 417 | 300 | 380 | |

| 600 | 870 | 272 | 6 | 6730 | 15600 | 240/600CA | - | 654 | 825 | 5 | 0.3 | 3.3 | 2.2 | 2.2 | 540 | 240 | 320 |

| 980 | 300 | 7.5 | 8970 | 18000 | 231/600CA | - | 662 | 925 | 6 | 0.3 | 3.4 | 2.3 | 2.2 | 985 | 200 | 280 | |

| 980 | 375 | 7.5 | 10200 | 21600 | 241/600 | 40037/600 | 662 | 925 | 6 | 0.39 | 2.6 | 1.8 | 1.7 | 1079 | 180 | 240 | |

| 1090 | 388 | 9.5 | 12700 | 24900 | 232/600CA | - | 670 | 1025 | 8 | 0.36 | 2.8 | 1.9 | 1.8 | 1590 | 170 | 220 | |

| 630 | 850 | 165 | 6 | 3970 | 9800 | 239/630CA | - | 685 | 805 | 5 | 0.18 | 5.6 | 3.8 | 3.7 | 280 | 280 | 360 |

| 920 | 212 | 7.5 | 4170 | 11500 | 230/630 | 30031/630 | 693 | 866 | 6 | 0.22 | 4.7 | 3.1 | 3.1 | 511 | 260 | 340 | |

| 920 | 212 | 7.5 | 4170 | 11500 | 230/630/W33 | 30031/630Y | 693 | 866 | 6 | 0.22 | 4.7 | 3.1 | 3.1 | 509 | 260 | 340 | |

| 920 | 290 | 7.5 | 7530 | 17300 | 240/630CA | - | 693 | 866 | 6 | 0.3 | 3.3 | 2.2 | 2.2 | 655 | 220 | 300 | |

| 1030 | 315 | 7.5 | 10500 | 20800 | 231/630CA | - | 693 | 974 | 6 | 30 | 3.4 | 2.3 | 2.2 | 1050 | 190 | 260 | |

| 1030 | 400 | 7.5 | 11600 | 24100 | 241/630/W33 | - | 693 | 974 | 6 | 0.38 | 2.7 | 1.8 | 1.7 | 1320 | 170 | 220 | |

| 1150 | 412 | 12 | 13400 | 25600 | 232/630CA | - | 712 | 1074 | 10 | 0.36 | 2.8 | 1.9 | 1.8 | 1850 | 140 | 180 | |

| Boundary dimensions | Basic load ratings | Part number | Installation | Constant | Axial | Mass | Limiting speeds | ||||||||||

| (mm) | |||||||||||||||||

| mm | kN | Current | Original | dbmin | Damin | ramax | e | Y2 | Y3 | Y0 | kg | r/min | |||||

| d | D | B | rmin | Cr | Cor | Grease | Oil | ||||||||||

| 670 | 820 | 112 | 4 | 2250 | 6400 | 238/670CA | - | 688 | 802 | 3 | 0.11 | 6.4 | 9.1 | 6.3 | 130 | 280 | 360 |

| 900 | 170 | 6 | 3700 | 9600 | 239/670/W33 | 30039/670Y | 698 | 872 | 5 | 0.17 | 4 | 5.9 | 4 | 317 | 260 | 340 | |

| 980 | 230 | 7.5 | 6850 | 15000 | 230/670 | 30031/670 | 706 | 944 | 6 | 0.21 | 3.2 | 4.8 | 3.2 | 657 | 240 | 320 | |

| 980 | 230 | 7.5 | 6850 | 15000 | 230/670/W33 | 30031/670Y | 706 | 944 | 6 | 0.21 | 3.2 | 4.8 | 3.2 | 655 | 240 | 320 | |

| 980 | 308 | 7.5 | 8450 | 20000 | 240/670CA | - | 706 | 944 | 6 | 0.28 | 2.4 | 3.6 | 2.5 | 792 | 200 | 280 | |

| 1090 | 336 | 7.5 | 10900 | 22400 | 231/670CA | - | 706 | 1054 | 6 | 30 | 2.3 | 3.4 | 2.2 | 1250 | 180 | 240 | |

| 1090 | 412 | 7.5 | 13800 | 29000 | 241/670CA | - | 706 | 1054 | 6 | 0.37 | 1.8 | 2.7 | 1.8 | 1600 | 160 | 200 | |

| 1220 | 438 | 12 | 15400 | 30500 | 232/670CA | - | 724 | 1166 | 10 | 0.35 | 1.9 | 2.9 | 1.8 | 2270 | 140 | 180 | |

| 710 | 950 | 180 | 6 | 3950 | 10500 | 239/710 | 30039/710 | 738 | 922 | 5 | 0.17 | 4 | 5.9 | 4 | 389 | 240 | 320 |

| 950 | 180 | 6 | 3950 | 10500 | 239/710/W33 | 30039/710Y | 738 | 922 | 5 | 0.17 | 4 | 5.9 | 4 | 387 | 240 | 320 | |

| 710 | 950 | 243 | 6 | 5870 | 15600 | 249/710 | - | 738 | 922 | 5 | 0.22 | 3 | 4.6 | 2.8 | 495 | 240 | 320 |

| 1030 | 236 | 7.5 | 6250 | 14900 | 230/710/W33 | 30031/710Y | 746 | 994 | 6 | 0.21 | 3.2 | 4.8 | 3.2 | 742 | 220 | 300 | |

| 1030 | 315 | 7.5 | 8970 | 22000 | 240/710CA | - | 746 | 994 | 6 | 0.27 | 2.5 | 3.7 | 2.5 | 895 | 190 | 260 | |

| 1150 | 345 | 9.5 | 12200 | 26000 | 231/710CA | - | 754 | 1106 | 8 | 0.28 | 2.4 | 3.6 | 2.5 | 1450 | 180 | 240 | |

| 1150 | 438 | 9.5 | 13900 | 30500 | 241/710/W33 | 40037/710Y | 754 | 1106 | 8 | 0.37 | 1.8 | 2.7 | 1.8 | 1900 | 150 | 190 | |

| 750 | 920 | 128 | 5 | 2930 | 8500 | 238/750 | - | 772 | 898 | 4 | 0.11 | 6.1 | 9.1 | 6.3 | 135 | 240 | 320 |

| 1000 | 185 | 6 | 5180 | 13200 | 239/750CA | - | 778 | 972 | 5 | 0.16 | 4.2 | 6.3 | 4 | 420 | 220 | 300 | |

| 1000 | 250 | 6 | 6560 | 18000 | 249/750 | - | 778 | 972 | 5 | 0.22 | 3 | 4.6 | 3.2 | 560 | 200 | 280 | |

| 1090 | 250 | 7.5 | 8450 | 18600 | 230/750CA | - | 786 | 1054 | 6 | 0.21 | 3.2 | 4.8 | 3.2 | 795 | 200 | 280 | |

| 1090 | 335 | 7.5 | 9950 | 24000 | 240/750CA | - | 786 | 1054 | 6 | 0.28 | 2.4 | 3.6 | 2.5 | 1065 | 180 | 240 | |

| 1220 | 365 | 9.5 | 13600 | 29000 | 231/750CA | - | 794 | 1176 | 8 | 0.28 | 2.4 | 3.6 | 2.5 | 1700 | 170 | 220 | |

| Boundary dimensions | Basic load ratings | Part number | Installation | Constant | Axial | Mass | Limiting speeds | ||||||||||

| (mm) | |||||||||||||||||

| mm | kN | Current | Original | dbmin | Damin | ramax | e | Y2 | Y3 | Y0 | kg | r/min | |||||

| d | D | B | rmin | Cr | Cor | Grease | Oil | ||||||||||

| 750 | 1220 | 475 | 9.5 | 17300 | 377500 | 241/750CA | - | 794 | 1176 | 8 | 0.37 | 1.8 | 2.7 | 1.8 | 2100 | 140 | 180 |

| 1360 | 475 | 15 | 18700 | 36500 | 232/750 | - | 814 | 1296 | 12 | 0.35 | 1.9 | 2.9 | 1.8 | 3050 | 130 | 170 | |

| 800 | 980 | 180 | 5 | 4140 | 12900 | 248/800 | - | 822 | 958 | 4 | 0.15 | 4.5 | 6.7 | 4.5 | 300 | 200 | 280 |

| 1060 | 195 | 6 | 5640 | 14300 | 239/800CA | - | 828 | 1032 | 5 | 0.16 | 4.2 | 6.3 | 4 | 470 | 180 | 240 | |

| 1060 | 258 | 6 | 6240 | 15200 | 249/800/W33 | 40039/800Y | 828 | 1032 | 5 | 0.21 | 3.52 | 4.8 | 3.2 | 638 | 180 | 240 | |

| 1150 | 258 | 7.5 | 8350 | 19100 | 230/800/W33 | 30031/800Y | 836 | 1114 | 6 | 0.2 | 3.4 | 5 | 3.2 | 986 | 190 | 260 | |

| 1150 | 345 | 7.5 | 10900 | 26300 | 240/800 | 40031/800 | 836 | 1114 | 6 | 0.27 | 2.5 | 3.7 | 2.5 | 1246 | 170 | 220 | |

| 1280 | 375 | 9.5 | 14800 | 31500 | 231/800CA | - | 844 | 1236 | 8 | 0.28 | 2.4 | 3.6 | 2.5 | 1920 | 160 | 200 | |

| 1280 | 475 | 9.5 | 10900 | 40500 | 241/800CA | - | 844 | 1236 | 8 | 0.35 | 1.9 | 2.9 | 1.8 | 2300 | 130 | 170 | |

| 850 | 1030 | 136 | 5 | 3340 | 10000 | 238/850 | - | 872 | 1008 | 4 | 0.11 | 6.1 | 9.1 | 6.3 | 240 | - | - |

| 1120 | 200 | 6 | 5330 | 15200 | 239/850 | 31139/850 | 878 | 1092 | 5 | 0.16 | 4.2 | 6.3 | 4 | 531 | - | - | |

| 850 | 1120 | 272 | 6 | 8170 | 22800 | 249/850 | - | 878 | 1092 | 5 | 0.22 | 3 | 4.6 | 2.8 | 740 | - | - |

| 1220 | 272 | 7.5 | 9370 | 21600 | 230/850 | - | 886 | 1184 | 6 | 0.2 | 3.4 | 5 | 3.2 | 1050 | - | - | |

| 1220 | 365 | 7.5 | 11600 | 28300 | 240/850 | 40031/850 | 886 | 1184 | 6 | 0.27 | 2.5 | 3.7 | 2.5 | 1398 | - | - | |

| 1360 | 400 | 12 | 16100 | 34500 | 231/850 | - | 904 | 1306 | 10 | 0.28 | 2.4 | 3.6 | 2.5 | 2200 | - | - | |

| 900 | 1090 | 190 | 5 | 4660 | 15300 | 248/900 | - | 922 | 1068 | 4 | 0.14 | 4.8 | 7.2 | 4.5 | 370 | - | - |

| 1180 | 206 | 6 | 6440 | 17000 | 239/900 | - | 928 | 1152 | 5 | 0.15 | 4.5 | 6.7 | 4.5 | 605 | - | - | |

| 1280 | 280 | 7.5 | 10100 | 23200 | 230/900 | - | 936 | 1244 | 6 | 0.2 | 3.4 | 5 | 3.2 | 1200 | - | - | |

| 1280 | 375 | 7.5 | 12800 | 31500 | 240/900/W33 | 40031/900Y | 936 | 1244 | 6 | 0.26 | 2.6 | 3.9 | 2.5 | 1783 | - | - | |

| 1420 | 515 | 12 | 21400 | 49000 | 241/900 | - | 954 | 1366 | 10 | 0.35 | 1.9 | 2.9 | 1.8 | 3350 | - | - | |

| 950 | 1250 | 224 | 7.5 | 7250 | 19600 | 239/950 | - | 986 | 1214 | 6 | 0.15 | 4.5 | 6.7 | 4.5 | 755 | - | - |

| 1250 | 300 | 7.5 | 9200 | 26000 | 249/950 | - | 986 | 1214 | 6 | 0.21 | 3.2 | 4.8 | 3.2 | 1000 | - | - | |

| Boundary dimensions | Basic load ratings | Part number | Installation | Constant | Axial | Mass | Limiting speeds | ||||||||||

| (mm) | |||||||||||||||||

| mm | kN | Current | Original | dbmin | Damin | ramax | e | Y2 | Y3 | Y0 | kg | r/min | |||||

| d | D | B | rmin | Cr | Cor | Grease | Oil | ||||||||||

| 950 | 1360 | 300 | 7.5 | 12000 | 28500 | 230/950 | - | 986 | 1324 | 6 | 0.2 | 3.4 | 5 | 3.2 | 1450 | - | - |

| 1360 | 412 | 7.5 | 14800 | 39000 | 240/950 | - | 986 | 1324 | 6 | 0.27 | 2.5 | 3.7 | 2.5 | 1990 | - | - | |

| 1000 | 1220 | 165 | 6 | 4660 | 14300 | 238/1000 | - | 1028 | 1192 | 5 | 0.12 | 5.6 | 8.4 | 5.6 | 410 | - | - |

| 1320 | 315 | 7.5 | 10400 | 29000 | 249/1000 | - | 1036 | 1284 | 6 | 0.21 | 3.2 | 4.8 | 3.2 | 1200 | - | - | |

| 1420 | 412 | 7.5 | 15300 | 38500 | 240/1000/W33 | 40031/1000 | 1036 | 1384 | 6 | 0.26 | 2.6 | 3.9 | 2.5 | 2117 | - | - | |

| 1580 | 462 | 12 | 21400 | 48000 | 231/1000 | - | 1054 | 1526 | 10 | 0.28 | 2.4 | 3.6 | 2.5 | 3500 | - | - | |

| 1580 | 580 | 12 | 22500 | 50000 | 241/1000 | - | 1054 | 1526 | 10 | 0.35 | 1.9 | 2.9 | 1.8 | 4300 | - | - | |

| 1060 | 1280 | 165 | 6 | 4770 | 15000 | 238/1060 | - | 1088 | 1252 | 5 | 0.11 | 6.1 | 9.1 | 6.3 | 435 | - | - |

| 1280 | 218 | 6 | 6100 | 20000 | 248/1060 | - | 1088 | 1252 | 5 | 0.14 | 4.8 | 7.2 | 4.5 | 570 | - | - | |

| 1400 | 250 | 7.5 | 9300 | 24400 | 239/1060CA/W33 | - | 1096 | 1364 | 6 | 0.16 | 4.2 | 6.3 | 4 | 1020 | - | - | |

| 1400 | 335 | 7.5 | 11500 | 32500 | 249/1060 | - | 1096 | 1364 | 6 | 0.21 | 3.2 | 4.8 | 3.2 | 1400 | - | - | |

| 1060 | 1500 | 325 | 9.5 | 13800 | 34000 | 230/1060 | - | 1104 | 1456 | 8 | 0.19 | 3.6 | 5.3 | 3.6 | 2250 | - | - |

| 1500 | 438 | 9.5 | 17300 | 45500 | 240/1060 | - | 1104 | 1456 | 8 | 0.26 | 2.6 | 3.9 | 2.5 | 2515 | - | - | |

| 1120 | 1360 | 243 | 6 | 7250 | 24000 | 248/1120 | - | 1148 | 1332 | 5 | 0.15 | 4.5 | 6.7 | 4.5 | 735 | - | - |

| 1460 | 335 | 7.5 | 11700 | 34500 | 249/1120 | - | 1156 | 1424 | 6 | 0.2 | 3.4 | 5 | 3.2 | 1500 | - | - | |

| 1580 | 462 | 9.5 | 18700 | 50000 | 240/1120 | - | 1164 | 1536 | 8 | 0.26 | 2.6 | 3.9 | 2.5 | 2905 | - | - | |

| 1180 | 1420 | 180 | 6 | 5870 | 18600 | 238/1180 | - | 1208 | 1392 | 5 | 0.11 | 6.1 | 9.1 | 6.3 | 575 | - | - |

| 1420 | 243 | 6 | 7710 | 27000 | 248/1180 | - | 1208 | 1392 | 5 | 0.14 | 4.8 | 7.2 | 4.5 | 770 | - | - | |

| 1540 | 272 | 7.5 | 11100 | 31000 | 239/1180 | - | 1216 | 1504 | 6 | 0.16 | 4.2 | 6.3 | 4 | 1400 | - | - | |

| 1540 | 355 | 7.5 | 13300 | 39000 | 249/1180 | - | 1216 | 1504 | 6 | 0.2 | 3.4 | 5 | 3.2 | 1800 | - | - | |

| 1250 | 1750 | 375 | 9.5 | 17900 | 45000 | 230/1250 | - | 1294 | 1706 | 8 | 0.19 | 3.6 | 5.3 | 3.6 | 2840 | - | - |

| 1320 | 1600 | 280 | 6 | 9780 | 33500 | 248/1320 | - | 1348 | 1572 | 5 | 0.15 | 4.5 | 6.7 | 4.5 | 1160 | - | - |

| 1320 | 1720 | 400 | 7.5 | 16100 | 49000 | 249/1320 | - | 1356 | 1684 | 6 | 0.21 | 3.2 | 4.8 | 3.2 | 2500 | - | - |

| 1500 | 1820 | 315 | 7.5 | 11700 | 40500 | 248/1500 | - | 1536 | 1784 | 6 | 0.15 | 4.5 | 6.7 | 4.5 | 1700 | - | - |

| 1950 | 450 | 9.5 | 20700 | 63000 | 249/1500 | - | 1544 | 1906 | 8 | 0.2 | 3.4 | 5 | 3.2 | 3550 | - | - | |

| 1800 | 2180 | 375 | 9.5 | 16800 | 60000 | 248/1800 | - | 1844 | 2136 | 8 | 0.15 | 4.5 | 6.7 | 4.5 | 2900 | - | - |

YOU MAY LIKE

VIEW MOREThrust Roller Bearing

VIEW MOREThrust Roller Bearing VIEW MORESpherical Roller Bearings

VIEW MORESpherical Roller Bearings VIEW MOREHigh Speed Tapered Roller Bearings

VIEW MOREHigh Speed Tapered Roller Bearings VIEW MORECone Tapered Roller Bearing

VIEW MORECone Tapered Roller Bearing VIEW MOREDouble Row Tapered Roller Bearing

VIEW MOREDouble Row Tapered Roller Bearing VIEW MORESingle Row Cylindrical Roller Bearing

VIEW MORESingle Row Cylindrical Roller Bearing VIEW MOREFour Row Tapered Roller Bearing

VIEW MOREFour Row Tapered Roller Bearing VIEW MORECylindrical Roller Bearings

VIEW MORECylindrical Roller Bearings