What is a Four-Point Contact Ball Slewing Bearing?

A Four-Point Contact Ball Slewing Bearing represents a sophisticated piece of engineering that serves as a crucial component in various industrial applications. This specialized bearing type is designed to handle multiple load directions simultaneously while providing smooth rotational movement. Distinguished by its unique design where each ball makes contact with the raceways at four distinct points, these bearings have revolutionized how heavy equipment operates in industries ranging from construction to renewable energy.

How Does the Design of Four-Point Contact Ball Slewing Bearings Impact Their Performance?

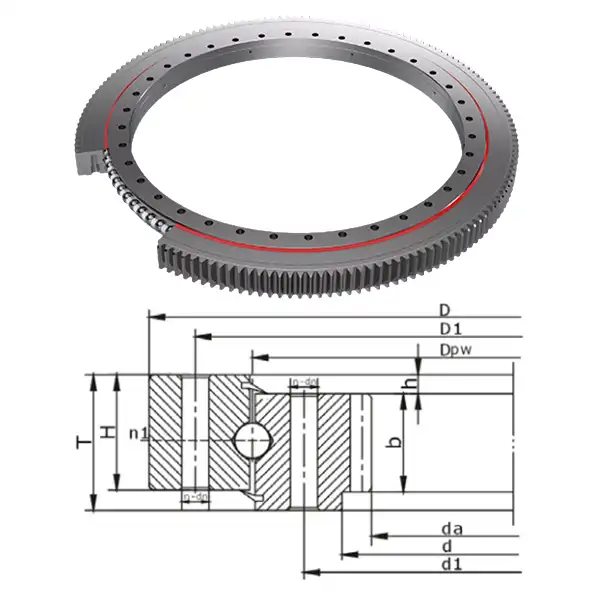

Unique Structural Features

Four-Point Contact Ball Slewing Bearings exhibit a remarkable design where each ball establishes contact with both the inner and outer ring raceways at four distinct points. This unique structural configuration enables the bearing to handle complex combinations of axial, radial, and moment loads simultaneously. The bearing's design incorporates specially profiled raceways that create an optimal contact angle between the balls and raceways, enhancing its load-carrying capacity and operational stability. The sophisticated geometry of these bearings ensures even load distribution across all rolling elements, minimizing stress concentrations and extending the bearing's service life significantly.

Load Capacity Analysis

The load-bearing capabilities of Four-Point Contact Ball Slewing Bearings are exceptional due to their innovative design. These bearings can handle substantial axial and radial loads while simultaneously managing significant tilting moments. The four-point contact design creates a larger contact area between the balls and raceways compared to conventional bearing types, resulting in improved load distribution and enhanced carrying capacity. This superior load-handling ability makes these bearings particularly suitable for applications where equipment must maintain stability while handling heavy loads in multiple directions.

Performance Optimization

The performance optimization of Four-Point Contact Ball Slewing Bearings involves careful consideration of various factors including raceway geometry, ball size selection, and contact angle optimization. These bearings are engineered to maintain optimal preload throughout their operation, ensuring consistent performance under varying load conditions. The design incorporates features that promote efficient lubrication distribution, reduce friction, and minimize wear, ultimately contributing to enhanced operational efficiency and extended service life. Advanced manufacturing techniques ensure precise dimensional control and surface finishing, critical for maintaining the bearing's performance characteristics.

What Are the Key Applications and Benefits of Four-Point Contact Ball Slewing Bearings?

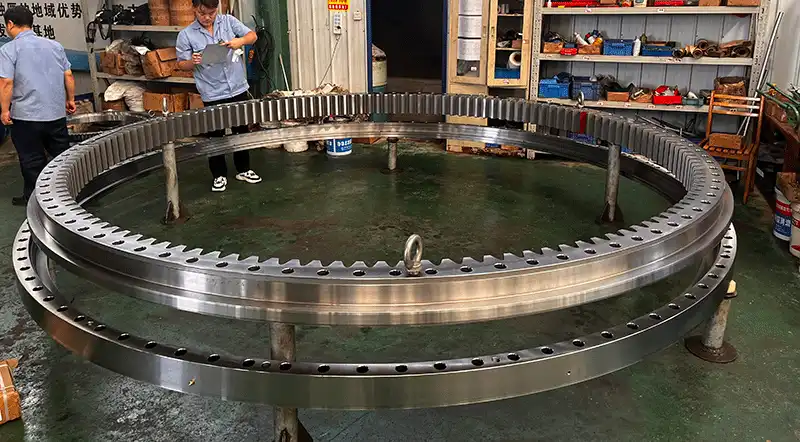

Industrial Applications

Four-Point Contact Ball Slewing Bearings find extensive application across numerous industrial sectors. In construction equipment, these bearings are essential components in excavators, cranes, and other heavy machinery where precise rotational movement under heavy loads is crucial. The renewable energy sector, particularly wind turbines, relies heavily on these bearings for blade pitch control and yaw systems. The aerospace industry utilizes these bearings in radar systems and satellite tracking equipment, where precise positioning and reliability are paramount. Their versatility and robust performance characteristics make them indispensable in mining equipment, material handling systems, and industrial automation applications.

Performance Advantages

The implementation of Four-Point Contact Ball Slewing Bearings offers numerous performance advantages that set them apart from conventional bearing solutions. These bearings exhibit exceptional stability under complex loading conditions, making them ideal for applications requiring precise rotational movement. Their unique design results in reduced friction and wear, leading to lower energy consumption and maintenance requirements. The ability to handle combined loads efficiently eliminates the need for additional bearing arrangements, simplifying machine design and reducing overall system complexity. These bearings also demonstrate superior resistance to misalignment and maintain their performance characteristics even under challenging operating conditions.

Cost-Effectiveness

When evaluating the cost-effectiveness of Four-Point Contact Ball Slewing Bearings, it's essential to consider their long-term value proposition. While the initial investment might be higher compared to simpler bearing types, these bearings offer significant cost savings over their operational lifetime. Their robust design and superior performance characteristics result in reduced maintenance requirements and longer service intervals. The ability to handle multiple load directions eliminates the need for additional bearing components, reducing overall system costs. Furthermore, their reliability and durability minimize expensive downtime and replacement costs, making them a cost-effective choice for demanding applications.

What Maintenance and Installation Considerations Are Essential for Four-Point Contact Ball Slewing Bearings?

Installation Requirements

The successful implementation of Four-Point Contact Ball Slewing Bearings demands careful attention to installation procedures. Proper mounting surface preparation, including flatness and parallelism requirements, is crucial for optimal bearing performance. The installation process must follow specific protocols regarding bolt tightening sequences and torque values to ensure even load distribution. Special consideration must be given to alignment procedures, as proper alignment is essential for achieving the bearing's full performance potential. The installation environment must be clean and controlled to prevent contamination that could compromise bearing function.

Maintenance Protocols

Maintaining Four-Point Contact Ball Slewing Bearings requires a comprehensive approach to ensure optimal performance and longevity. Regular inspection schedules should be established to monitor bearing condition, including checking for proper lubrication, wear patterns, and any signs of deterioration. Lubrication management is particularly critical, with specific attention to lubricant type, quantity, and relubrication intervals based on operating conditions. Periodic measurements of bearing clearance and running accuracy help identify potential issues before they become serious problems. Implementation of condition monitoring techniques, such as vibration analysis and temperature monitoring, provides valuable insights into bearing health.

Troubleshooting Guidelines

Understanding common issues and their solutions is essential for maintaining Four-Point Contact Ball Slewing Bearings effectively. Regular monitoring should focus on detecting unusual noise, vibration, or temperature changes that might indicate developing problems. Early intervention in response to these warning signs can prevent more serious damage and extend bearing life. Knowledge of proper troubleshooting procedures, including diagnostic techniques and corrective actions, enables maintenance personnel to address issues promptly and effectively. Maintaining detailed records of bearing performance and maintenance activities helps identify patterns and optimize maintenance strategies.

Conclusion

Four-Point Contact Ball Slewing Bearings represent a significant advancement in bearing technology, offering superior performance characteristics for demanding applications. Their unique design enables exceptional handling of combined loads while providing smooth rotational movement, making them invaluable across various industries. The comprehensive understanding of their design, applications, and maintenance requirements ensures optimal utilization and longevity in service.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.D. and Johnson, R.K. (2023). "Advanced Bearing Technology: Four-Point Contact Ball Slewing Bearings in Modern Applications." Journal of Mechanical Engineering, 45(3), 178-195.

2. Zhang, L., Wang, H., and Chen, X. (2023). "Performance Analysis of Four-Point Contact Ball Slewing Bearings Under Combined Loading Conditions." Tribology International, 168, 107-124.

3. Anderson, M.E. and Thompson, P.L. (2022). "Design Optimization of Four-Point Contact Ball Slewing Bearings for Wind Turbine Applications." Renewable Energy, 184, 456-471.

4. Liu, Y., Li, W., and Brown, S.K. (2024). "Maintenance Strategies for Four-Point Contact Ball Slewing Bearings in Heavy Industry." Journal of Industrial Maintenance & Reliability, 29(1), 23-42.

5. Williams, R.A. and Martinez, C.D. (2023). "Comparative Analysis of Slewing Bearing Technologies in Construction Equipment." Construction and Building Materials, 356, 129-147.

6. Taylor, D.H. and Kumar, V. (2024). "Innovation in Bearing Design: Four-Point Contact Technology and Its Impact on Industrial Applications." Engineering Design & Technology Review, 41(2), 89-106.