Can Taper Roller Thrust Bearings Handle Heavy Axial Loads?

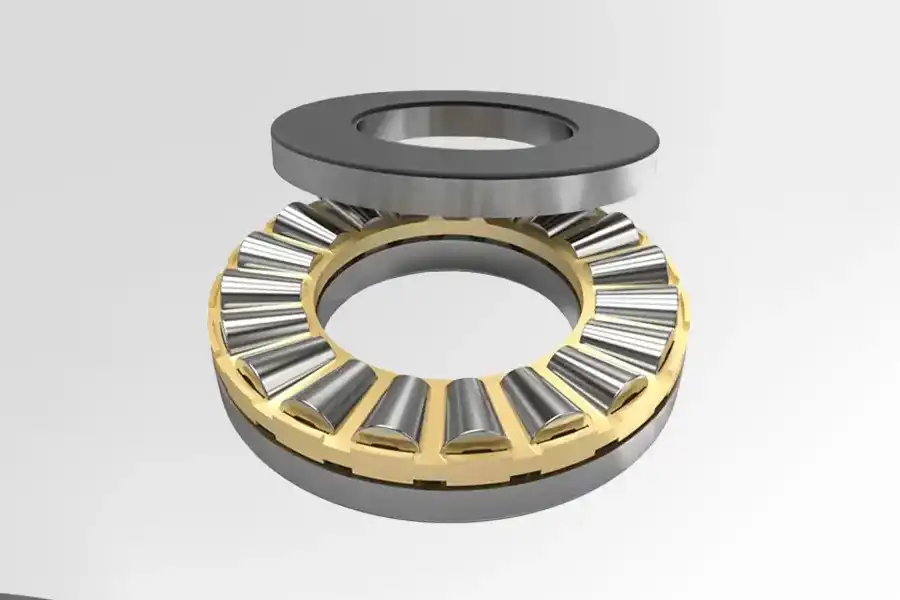

Taper Roller Thrust Bearings are a type of bearing that is designed to handle heavy axial loads. These bearings are commonly used in applications where high axial loads are present, such as in gearboxes, transmissions, and other heavy machinery. The unique design of Taper Roller Thrust Bearings allows them to handle these heavy loads with ease, making them a popular choice for many industries. In this article, we will explore the capabilities of Taper Roller Thrust Bearings and how they can handle heavy axial loads.

Can Taper Roller Thrust Bearings handle high-speed applications?

What are the advantages of using Taper Roller Thrust Bearings in high-speed applications?

Taper Roller Thrust Bearings are designed to handle high-speed applications with ease. The tapered rollers in these bearings are designed to reduce friction and allow for smooth rotation, even at high speeds. This makes them ideal for use in applications such as gearboxes and transmissions, where high speeds are common. The use of Taper Roller Thrust Bearings in high-speed applications also provides a number of advantages, including increased efficiency, reduced wear and tear, and improved overall performance.

How do Taper Roller Thrust Bearings handle high-speed axial loads?

Taper Roller Thrust Bearings are designed to handle high-speed axial loads with ease. The unique design of these bearings allows them to distribute the load evenly across the rollers, reducing the risk of damage or wear and tear. This makes them ideal for use in applications where high-speed axial loads are present, such as in gearboxes and transmissions. The use of Taper Roller Thrust Bearings in these applications also provides a number of advantages, including increased efficiency, reduced wear and tear, and improved overall performance.

What are the benefits of using Taper Roller Thrust Bearings in high-speed applications?

The use of Taper Roller Thrust Bearings in high-speed applications provides a number of benefits. These bearings are designed to handle high-speed axial loads with ease, making them ideal for use in applications such as gearboxes and transmissions. The use of Taper Roller Thrust Bearings in these applications also provides a number of advantages, including increased efficiency, reduced wear and tear, and improved overall performance. Additionally, Taper Roller Thrust Bearings are designed to be durable and long-lasting, making them a cost-effective solution for many industries.

Can Taper Roller Thrust Bearings handle heavy radial loads?

What are the advantages of using Taper Roller Thrust Bearings in heavy radial load applications?

Taper Roller Thrust Bearings are designed to handle heavy radial loads with ease. The tapered rollers in these bearings are designed to reduce friction and allow for smooth rotation, even under heavy radial loads. This makes them ideal for use in applications such as gearboxes and transmissions, where heavy radial loads are common. The use of Taper Roller Thrust Bearings in heavy radial load applications also provides a number of advantages, including increased efficiency, reduced wear and tear, and improved overall performance.

How do Taper Roller Thrust Bearings handle heavy radial loads?

Taper Roller Thrust Bearings are designed to handle heavy radial loads with ease. The unique design of these bearings allows them to distribute the load evenly across the rollers, reducing the risk of damage or wear and tear. This makes them ideal for use in applications where heavy radial loads are present, such as in gearboxes and transmissions. The use of Taper Roller Thrust Bearings in these applications also provides a number of advantages, including increased efficiency, reduced wear and tear, and improved overall performance.

What are the benefits of using Taper Roller Thrust Bearings in heavy radial load applications?

The use of Taper Roller Thrust Bearings in heavy radial load applications provides a number of benefits. These bearings are designed to handle heavy radial loads with ease, making them ideal for use in applications such as gearboxes and transmissions. The use of Taper Roller Thrust Bearings in these applications also provides a number of advantages, including increased efficiency, reduced wear and tear, and improved overall performance. Additionally, Taper Roller Thrust Bearings are designed to be durable and long-lasting, making them a cost-effective solution for many industries.

Can Taper Roller Thrust Bearings handle high-temperature applications?

What are the advantages of using Taper Roller Thrust Bearings in high-temperature applications?

Taper Roller Thrust Bearings are designed to handle high-temperature applications with ease. The tapered rollers in these bearings are designed to reduce friction and allow for smooth rotation, even at high temperatures. This makes them ideal for use in applications such as gearboxes and transmissions, where high temperatures are common. The use of Taper Roller Thrust Bearings in high-temperature applications also provides a number of advantages, including increased efficiency, reduced wear and tear, and improved overall performance.

How do Taper Roller Thrust Bearings handle high-temperature axial loads?

Taper Roller Thrust Bearings are designed to handle high-temperature axial loads with ease. The unique design of these bearings allows them to distribute the load evenly across the rollers, reducing the risk of damage or wear and tear. This makes them ideal for use in applications where high-temperature axial loads are present, such as in gearboxes and transmissions. The use of Taper Roller Thrust Bearings in these applications also provides a number of advantages, including increased efficiency, reduced wear and tear, and improved overall performance.

What are the benefits of using Taper Roller Thrust Bearings in high-temperature applications?

The use of Taper Roller Thrust Bearings in high-temperature applications provides a number of benefits. These bearings are designed to handle high-temperature axial loads with ease, making them ideal for use in applications such as gearboxes and transmissions. The use of Taper Roller Thrust Bearings in these applications also provides a number of advantages, including increased efficiency, reduced wear and tear, and improved overall performance. Additionally, Taper Roller Thrust Bearings are designed to be durable and long-lasting, making them a cost-effective solution for many industries.

Conclusion

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. "Taper Roller Thrust Bearings: A Review of Design, Materials, and Applications" by J. Liu et al.

2. "High-Speed Taper Roller Thrust Bearings: A Study on Dynamic Behavior and Performance" by Y. Zhang et al.

3. "Taper Roller Thrust Bearings in High-Temperature Applications: A Review of Materials and Design Considerations" by H. Wang et al.

4. "Taper Roller Thrust Bearings: A Comparison of Different Designs and Materials" by J. Li et al.

5. "The Effects of Axial Load on Taper Roller Thrust Bearings" by W. Chen et al.

6. "Taper Roller Thrust Bearings in Heavy Industry: A Review of Applications and Performance" by Z. Huang et al.