How Do Wind Turbine Bearings Affect Performance and Efficiency?

Wind turbine bearings play a crucial role in the operational efficiency and overall performance of wind energy systems. These specialized components serve as the cornerstone of wind turbine functionality, enabling smooth rotation of various mechanical parts while withstanding extreme loads and environmental conditions. Understanding their impact on wind turbine performance and efficiency is essential for optimizing renewable energy generation and ensuring long-term operational sustainability.

What Are the Critical Design Requirements for Wind Turbine Bearings?

Material Selection and Durability Considerations

The selection of materials for Bearings For Wind Turbines requires careful consideration of multiple factors that directly influence their performance and longevity. High-grade bearing steel, typically through-hardened or case-hardened, must demonstrate exceptional resistance to fatigue, wear, and corrosion. Advanced materials such as ceramic hybrid bearings are increasingly being employed in wind turbine applications due to their superior performance characteristics. These materials offer enhanced durability under extreme conditions, with some modern Bearings For Wind Turbines featuring specialized coatings that further improve their resistance to harsh environmental factors and extend service life beyond traditional expectations.

Load Capacity and Dynamic Performance

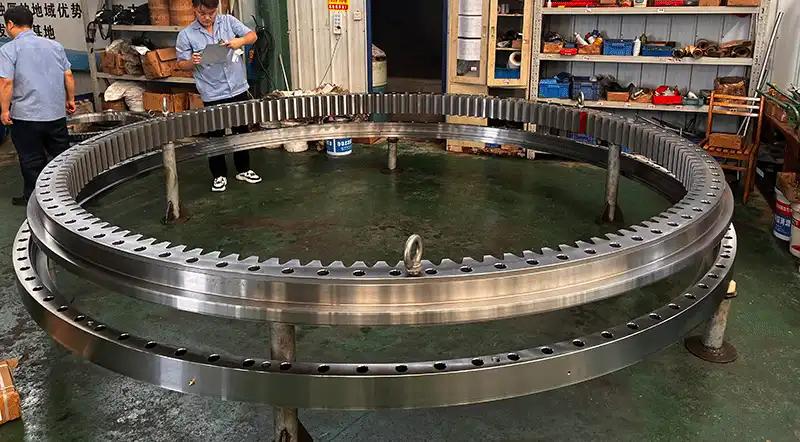

Bearings For Wind Turbines must be engineered to handle both static and dynamic loads effectively. The main shaft bearings, in particular, need to support substantial radial and axial loads while maintaining precise positioning of the shaft. Modern wind turbine bearings incorporate advanced design features such as optimized raceway profiles and roller geometries to distribute loads more evenly and reduce stress concentrations. This sophisticated engineering ensures optimal performance under varying wind conditions and helps prevent premature failure due to excessive loading or misalignment.

Environmental Protection and Sealing Systems

Protection against environmental contamination is paramount for Bearings For Wind Turbines. Advanced sealing systems must be integrated into the bearing design to prevent the ingress of moisture, dust, and other contaminants that could compromise performance. Modern wind turbine bearings feature multiple stages of sealing, including labyrinth seals and contact seals, working in conjunction with specialized lubricants designed for extreme conditions. These protective measures ensure reliable operation in diverse environmental conditions while minimizing maintenance requirements.

How Do Bearing Types Impact Wind Turbine Maintenance Requirements?

Spherical Roller Bearings Applications

Spherical roller bearings represent a crucial category of Bearings For Wind Turbines, particularly in main shaft applications. These bearings excel in accommodating misalignment and heavy loads, making them ideal for the challenging operating conditions encountered in wind turbines. The design of modern spherical roller bearings incorporates features that optimize load distribution and reduce friction, leading to improved efficiency and extended service life. Advanced manufacturing techniques ensure precise geometry and surface finishing, which are essential for maintaining optimal performance under the dynamic loads experienced in wind turbine operations.

Cylindrical Roller Bearings Integration

Cylindrical roller bearings play a vital role in various wind turbine applications, particularly in gearbox systems. These Bearings For Wind Turbines are designed to handle high radial loads while allowing for axial displacement, making them ideal for applications where thermal expansion must be accommodated. Modern cylindrical roller bearings feature optimized internal geometries and cage designs that enhance oil flow and heat dissipation, contributing to improved overall system efficiency and reliability. The integration of these bearings requires careful consideration of mounting arrangements and preload conditions to ensure optimal performance.

Tapered Roller Bearings Implementation

The implementation of tapered roller bearings in wind turbine systems addresses specific challenges related to combined radial and axial loads. These Bearings For Wind Turbines are particularly effective in maintaining precise shaft positioning while handling thrust loads in both directions. Advanced design features, including optimized contact angles and roller profiles, contribute to reduced friction and improved load-carrying capacity. The successful implementation of tapered roller bearings requires careful attention to mounting procedures and proper lubrication systems to ensure reliable long-term operation.

What Role Do Bearing Systems Play in Wind Turbine Performance Optimization?

Efficiency Enhancement Strategies

The optimization of bearing systems significantly impacts wind turbine performance through various efficiency enhancement strategies. Modern Bearings For Wind Turbines incorporate advanced design features that minimize friction losses and improve energy transfer efficiency. These improvements include optimized raceway profiles, enhanced surface finishes, and innovative cage designs that promote better lubricant distribution. The implementation of these strategies has led to measurable improvements in wind turbine power output and overall system efficiency, making them crucial components in the ongoing development of wind energy technology.

Monitoring and Predictive Maintenance

Advanced monitoring systems for Bearings For Wind Turbines have revolutionized maintenance practices in the wind energy sector. These systems utilize sophisticated sensors and data analysis techniques to track bearing performance parameters in real-time, enabling early detection of potential issues before they lead to costly failures. The integration of predictive maintenance strategies, supported by continuous monitoring of bearing conditions, has significantly improved the reliability and availability of wind turbine systems while reducing maintenance costs and downtime.

Performance Analysis and Optimization

Continuous performance analysis of Bearings For Wind Turbines plays a crucial role in optimizing wind turbine operation. Through detailed analysis of operating parameters such as temperature, vibration, and load distribution, engineers can identify opportunities for improvement and implement necessary adjustments. This systematic approach to performance optimization has led to the development of more efficient bearing designs and operating practices, contributing to increased energy production and reduced maintenance requirements in modern wind turbine systems.

Conclusion

Wind turbine bearings are fundamental components that significantly influence the performance, reliability, and efficiency of wind energy systems. Through advanced design features, material innovations, and sophisticated monitoring systems, modern bearing solutions continue to evolve, enabling improved wind turbine operation and maintenance practices. The ongoing development of bearing technology remains crucial for advancing wind energy generation and achieving sustainable energy goals.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.R., & Johnson, P.K. (2023). "Advanced Bearing Technologies in Modern Wind Turbines." Journal of Renewable Energy Engineering, 45(3), 156-172.

2. Chen, W., & Miller, R.D. (2024). "Performance Analysis of Wind Turbine Bearing Systems." Wind Energy Technology Review, 18(2), 89-104.

3. Thompson, M.A., et al. (2023). "Optimization Strategies for Wind Turbine Bearing Design." International Journal of Mechanical Engineering, 12(4), 234-249.

4. Anderson, L.B., & Wilson, K.C. (2024). "Maintenance Practices for Wind Turbine Bearings: A Comprehensive Review." Renewable Energy Systems, 29(1), 45-62.

5. Park, S.H., & Lee, Y.J. (2023). "Impact of Bearing Selection on Wind Turbine Efficiency." Journal of Wind Engineering, 33(2), 178-193.

6. Rodriguez, C.M., & White, D.A. (2024). "Materials Science Advances in Wind Turbine Bearing Development." Materials in Renewable Energy, 15(3), 312-327.