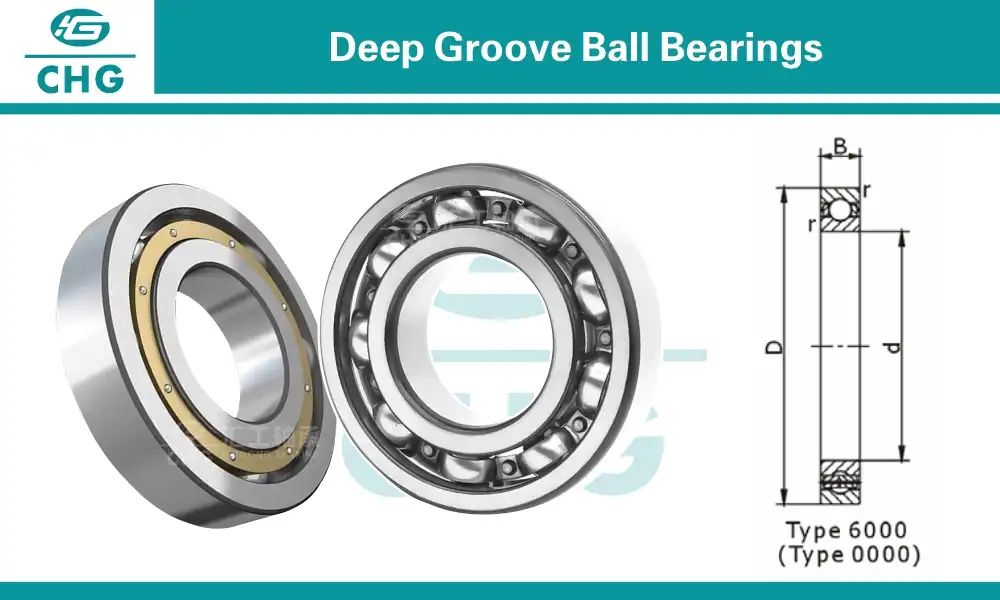

Ball Bearing Single Row Deep Groove

2. Feature:Deep groove ball bearings are commonly used in a number of applications as their simple structures and convenient using. They mainly carry radial loads, but also can carry combined loads as same as angular contact ball bearings when the radial clearance increases. They may carry pure axial loads when the speed is high and thrust ball bearings are not suitable. Comparing with other bearings, deep groove ball bearings have lower friction coefficient and higher limiting speed, but can not carry heavy loads.

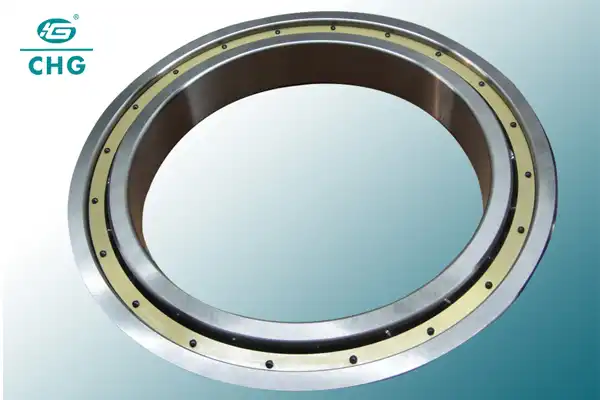

3. Cage:Deep groove ball bearings commonly adopt ribbon steel pressed cages, and metal machined solid cages are often for large-size deep groove ball bearings.

4. Application:Deep groove ball bearings are widely used in automotives, tractors, machine tools, generators, water-pumps,agriculture machinery, textile machinery,etc.

5. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

What is a Ball Bearing Single Row Deep Groove?

A Ball Bearing Single Row Deep Groove is a type of rolling bearing designed to support radial loads and a moderate degree of axial loads in both directions. Known for their high precision, reliability, and durability, these bearings are widely used in various industries, including metallurgy, mining, and manufacturing. The deep groove design allows the bearing to maintain stability even under heavy loads and high-speed operations, making it a preferred choice for critical equipment such as blast furnaces, rolling mills, crushers, and vibrating screens.

CHG Bearing: Your Trusted Partner for Ball Bearing Single Row Deep Groove

At CHG Bearing, we pride ourselves on being a leading manufacturer and supplier of high-quality Ball Bearing Single Row Deep Groove products. With over 30 years of industry experience and collaboration with numerous large companies, we have developed a strong reputation for excellence. Our commitment to quality is reflected in our 50+ invention patents and certifications, including ISO9001 for quality management and ISO14001 for environmental management.

Why Choose CHG Bearing?

- Customization & Solutions: We offer tailored solutions to meet the specific needs of different working conditions, ensuring optimal performance and longevity of our bearings.

- Proven Expertise: With decades of experience, our team is equipped to handle complex projects, providing technical support and innovative solutions to our clients.

- Certified Quality: Our products are manufactured under strict quality control processes, ensuring they meet the highest standards required by the industry.

For inquiries or to discuss your specific requirements, feel free to contact us at sale@chg-bearing.com.

Technical Specifications

| Parameter | Specification |

|---|---|

| Bearing Type | Single Row Deep Groove Ball Bearing |

| Material | Chrome Steel, Stainless Steel |

| Inner Diameter (ID) | 10mm - 300mm |

| Outer Diameter (OD) | 30mm - 500mm |

| Width | 8mm - 120mm |

| Load Capacity | 1kN - 100kN |

| Operating Temperature | -30°C to +150°C |

| Sealing Type | Open, Sealed, Shielded |

| Lubrication | Grease, Oil, Customization |

Benefits of Using Ball Bearing Single Row Deep Groove

- High Precision & Stability: Designed to provide smooth operation under high-speed conditions, these bearings minimize friction, ensuring efficient performance.

- Long Life & Durability: Engineered with high-quality materials and advanced manufacturing processes, our bearings offer long service life even in harsh environments.

- Versatility: Suitable for various applications, from heavy machinery in metallurgy to high-speed conveyors in manufacturing.

- Cost-Effective: Offering excellent value for money, our bearings reduce maintenance costs and downtime, contributing to higher productivity.

Applications

These bearings are versatile and used in a wide range of applications, including:

- Metallurgical Equipment: Blast furnaces, rolling mills, and steelmaking machinery.

- Mining Machinery: Jaw crushers, impact crushers, vibrating screens, and feeders.

- Manufacturing Equipment: Conveyors, pumps, electric motors, and gearboxes.

Installation Guide

Proper installation of Ball Bearing Single Row Deep Groove bearings is crucial for optimal performance. Follow these steps for a successful installation:

- Clean the Bearing and Housing: Ensure that both the bearing and housing are free from dirt, dust, and debris.

- Apply Lubricant: Use the appropriate lubricant based on the operating conditions and manufacturer’s recommendations.

- Align the Bearing: Carefully align the bearing with the housing to avoid misalignment, which can cause premature wear.

- Press Fit: Use a press to fit the bearing into the housing, applying even pressure to prevent damage.

- Secure the Bearing: Once installed, secure the bearing in place using the appropriate retaining rings or caps.

Maintenance and Care

- Regular Inspection: Check for signs of wear, noise, or vibration, and replace the bearing if necessary.

- Re-lubrication: Depending on the operating conditions, re-lubricate the bearings at regular intervals to maintain optimal performance.

- Temperature Monitoring: Monitor the operating temperature of the bearings to ensure they remain within the recommended range.

FAQ

Q: How do I choose the right Ball Bearing Single Row Deep Groove for my application?

A: Consider factors such as load capacity, speed, operating environment, and size requirements. Our technical team is available to help you select the best bearing for your needs.

Q: What are the delivery times for custom bearings?

A: Delivery times depend on the complexity of the customization. We strive to offer fast delivery, typically within 4-6 weeks for custom orders.

Q: Can I request a sample before placing a bulk order?

A: Yes, we offer samples for testing and evaluation before committing to a larger purchase.

Q: How do I maintain my bearings in harsh environments?

A: Use appropriate seals and lubricants, and follow our maintenance guidelines to ensure long-lasting performance.

Customer Reviews

_"We’ve been using CHG Bearing’s Single Row Deep Groove Ball Bearings in our steel mill for over five years. The quality and durability are unmatched, and their technical support is always top-notch."

- Mark T., Production Manager_

_"CHG Bearing offers the best customization options for our mining equipment needs. Their bearings have significantly reduced our downtime and maintenance costs."

- Sarah L., Technical Engineer_

Contact Us

Ready to experience the benefits of Ball Bearing Single Row Deep Groove bearings? Contact us today to discuss your requirements and get a quote.

Email: sale@chg-bearing.com

Phone: +86-123-4567-890

Address: No.123 Bearing Street, Industrial Zone, CHG City, China

| BounDary dimension | Basic load ratings | Designations | Mass | installation dimension | Limiting speeds | ||||||||

| mm | kN | mm | r/min | ||||||||||

| d | D | B | rmin | Cr | Cor | Current | Original | kg | damin | Damax | ramax | Grease | Oil |

| 150 | 190 | 20 | 1.1 | 49.1 | 58.5 | 6830 | 1000830 | 1.15 | 156.6 | 183.5 | 1 | 3000 | 3600 |

| 210 | 28 | 2 | 85 | 90.5 | 6930 | 1000930H | 2.59 | 159 | 201 | 2 | 2800 | 3400 | |

| 225 | 24 | 1.1 | 91.9 | 98.5 | 16030 | 7000130 | 3.62 | 156.5 | 218.5 | 1 | 2600 | 3000 | |

| 225 | 35 | 2.1 | 132 | 125 | 6030 | 130 | 4.24 | 161 | 214 | 2 | 2600 | 3000 | |

| 270 | 45 | 3 | 203 | 199 | 6230 | 230 | 10 | 163 | 257 | 2.5 | 1900 | 2500 | |

| 320 | 65 | 4 | 288 | 295 | 6330 | 330 | 22.7 | 166 | 304 | 3 | 1800 | 2300 | |

| 160 | 200 | 20 | 1.1 | 48.5 | 61 | 6832 | 1000832 | 1.23 | 166.5 | 193.5 | 1 | 2800 | 3400 |

| 220 | 28 | 2 | 87 | 96 | 6932 | 1000932H | 2.71 | 169 | 211 | 2 | 2600 | 3200 | |

| 240 | 25 | 1.5 | 99 | 108 | 16032 | 7000132 | 4.2 | 168 | 232 | 1.5 | 2400 | 3000 | |

| 240 | 38 | 2.1 | 145 | 138 | 6032 | 132 | 5.15 | 171 | 229 | 2 | 2400 | 3000 | |

| 290 | 48 | 3 | 215 | 218 | 6232 | 232H | 14.5 | 173 | 277 | 2.5 | 1900 | 2400 | |

| 340 | 68 | 4 | 313 | 340 | 6332 | 332 | 29 | 176 | 324 | 3 | 1800 | 2200 | |

| 170 | 215 | 22 | 1.1 | 61.5 | 78 | 6834 | 1000834 | 1.9 | 176.5 | 208.5 | 1 | 2600 | 3200 |

| 230 | 28 | 2 | 88.8 | 100 | 6934 | 1000934 | 2.85 | 179 | 221 | 2 | 2400 | 3000 | |

| 260 | 28 | 1.5 | 118 | 130 | 16034 | 7000134 | 5.71 | 178 | 252 | 1.5 | 2200 | 2800 | |

| 260 | 42 | 2.1 | 170 | 170 | 6034 | 134 | 6.89 | 181 | 249 | 2 | 2200 | 2800 | |

| 310 | 52 | 4 | 245 | 260 | 6234 | 234 | 15.8 | 186 | 294 | 3 | 1900 | 2400 | |

| 360 | 72 | 4 | 335 | 378 | 6334 | 334 | 36.6 | 286 | 344 | 3 | 1700 | 2000 | |

| 180 | 225 | 22 | 1.1 | 62.3 | 78.5 | 6836 | 1000836 | 1.72 | 186.5 | 218.5 | 1 | 2400 | 3000 |

| 250 | 33 | 2 | 119 | 133 | 6936 | 1000936H | 4.16 | 189 | 241 | 2 | 2200 | 2800 | |

| 260 | 34 | 2 | 140 | 147 | 61936X3 | 736 | 6.1 | 2100 | 2700 | ||||

| 280 | 31 | 2 | 145 | 157 | 16036 | 7000136 | 7.5 | 189 | 271 | 2 | 2000 | 2600 | |

| 280 | 46 | 2.1 | 188 | 198 | 6036 | 136 | 8.88 | 191 | 269 | 2 | 2000 | 2600 | |

| 320 | 52 | 4 | 262 | 285 | 6236 | 236 | 15.9 | 196 | 304 | 3 | 1800 | 2200 | |

| 380 | 75 | 4 | 355 | 405 | 6336 | 336 | 43.1 | 196 | 364 | 2 | 1600 | 2000 | |

| BounDary dimension | Basic load ratings | Designations | Mass | installation dimension | Limiting speeds | ||||||||

| mm | kN | mm | r/min | ||||||||||

| d | D | B | rmin | Cr | Cor | Current | Original | kg | damin | Damax | ramax | Grease | Oil |

| 190 | 240 | 24 | 1.5 | 75.1 | 93.5 | 6838 | 1000838H | 2.53 | 198 | 232 | 1.5 | 2200 | 2800 |

| 260 | 33 | 2 | 117 | 133 | 6938 | 1000938H | 5.18 | 199 | 251 | 2 | 2200 | 2800 | |

| 290 | 31 | 2 | 149 | 168 | 16038 | 7000138 | 7.78 | 199 | 281 | 2 | 2000 | 2600 | |

| 290 | 46 | 2.1 | 188 | 201 | 6038 | 138K1 | 9.39 | 201 | 279 | 2 | 2000 | 2600 | |

| 340 | 55 | 4 | 285 | 322 | 6238 | 238 | 22.3 | 206 | 324 | 3 | 1700 | 2000 | |

| 400 | 78 | 5 | 355 | 415 | 6338 | 338 | 49.7 | 210 | 380 | 4 | 1600 | 1900 | |

| 200 | 250 | 24 | 1.5 | 74 | 98 | 6840 | 1000840H | 2.67 | 208 | 242 | 1.5 | 2200 | 2800 |

| 280 | 38 | 2.1 | 149 | 168 | 6940 | 1000940H | 7.28 | 211 | 269 | 2 | 2000 | 2600 | |

| 310 | 34 | 2 | 167 | 191 | 16040 | 7000140 | 10 | 209 | 301 | 2 | 1900 | 2400 | |

| 310 | 51 | 2.1 | 207 | 226 | 6040 | 140 | 12 | 211 | 299 | 2 | 1900 | 2400 | |

| 360 | 58 | 4 | 288 | 332 | 6240 | 240 | 26.7 | 216 | 344 | 3 | 1700 | 2000 | |

| 420 | 80 | 5 | 380 | 445 | 6340 | 340 | 55.3 | 220 | 400 | 4 | 1500 | 1800 | |

| 220 | 270 | 24 | 1.5 | 76.5 | 97.8 | 6844 | 1000844H | 2.9 | 228 | 262 | 1.5 | 1900 | 2400 |

| 300 | 38 | 2.1 | 152 | 178 | 6944 | 1000944 | 7.88 | 231 | 289 | 2 | 1900 | 2400 | |

| 340 | 37 | 2.1 | 180 | 217 | 16044 | 7000144 | 13.1 | 231 | 329 | 2 | 1800 | 2200 | |

| 340 | 56 | 3 | 252 | 268 | 6044 | 144 | 18.6 | 233 | 327 | 2.5 | 1800 | 2200 | |

| 400 | 65 | 4 | 355 | 365 | 6244 | 244 | 37.4 | 236 | 384 | 3 | 1500 | 1800 | |

| 460 | 88 | 5 | 410 | 520 | 6344 | 344 | 73.9 | 240 | 440 | 4 | 1300 | 1600 | |

| 240 | 300 | 28 | 2 | 83.5 | 108 | 6848 | 1000848 | 4.48 | 249 | 291 | 2 | 1800 | 2200 |

| 320 | 38 | 2.1 | 154 | 190 | 61948M | 1000948H | 8.49 | 251 | 309 | 2 | 1800 | 2200 | |

| 360 | 37 | 2.1 | 196 | 243 | 16048 | 7000148 | 13.9 | 251 | 349 | 2 | 1700 | 2000 | |

| 360 | 56 | 3 | 270 | 292 | 6048 | 148 | 19.9 | 253 | 347 | 2.5 | 1700 | 2000 | |

| 440 | 72 | 4 | 358 | 467 | 6248 | 248 | 50.5 | 256 | 424 | 3 | 1300 | 1600 | |

| 500 | 95 | 5 | 470 | 625 | 6348 | 348 | 94.4 | 260 | 480 | 4 | 1100 | 1400 | |

| BounDary dimensious | Basic load ratings | Designations | Mass | installation dimension | Limiting speeds | ||||||||

| mm | kN | mm | r/min | ||||||||||

| d | D | B | rmin | Cr | Cor | Current | Original | kg | damin | Damax | ramax | Grease | Oil |

| 260 | 320 | 28 | 2 | 101 | 148 | 61852M | 1000852H | 4.84 | 269 | 311 | 2 | 1700 | 2000 |

| 360 | 46 | 2.1 | 210 | 268 | 61952M | 1000952H | 14 | 271 | 349 | 2 | 1600 | 1900 | |

| 400 | 44 | 3 | 237 | 310 | 16052 | 7000152 | 21.1 | 273 | 387 | 2.5 | 1500 | 1800 | |

| 400 | 65 | 4 | 291 | 375 | 6052M | 152H | 29.4 | 276 | 384 | 3 | 1500 | 1800 | |

| 480 | 80 | 5 | 400 | 540 | 6252 | 252 | 67 | 280 | 460 | 4 | 1100 | 1400 | |

| 540 | 102 | 6 | 505 | 710 | 6352 | 352 | 118 | 284 | 516 | 5 | 1000 | 1300 | |

| 280 | 350 | 33 | 2 | 133 | 191 | 61856 | 1000856 | 7.2 | 289 | 341 | 2 | 1600 | 1900 |

| 380 | 46 | 2.1 | 209 | 272 | 61956M | 1000956H | 15.1 | 291 | 369 | 2 | 1500 | 1800 | |

| 420 | 44 | 3 | 243 | 330 | 16056 | 7000156 | 22.7 | 293 | 407 | 2.5 | 1400 | 1700 | |

| 420 | 65 | 4 | 300 | 410 | 6056 | 156 | 31.2 | 296 | 404 | 3 | 1400 | 1700 | |

| 500 | 80 | 5 | 400 | 550 | 6256 | 256 | 70.4 | 300 | 480 | 4 | 1100 | 1400 | |

| 580 | 108 | 6 | 570 | 840 | 6356 | 356 | 144 | 304 | 556 | 5 | 950 | 1200 | |

| 300 | 360 | 25 | 2 | 105 | 166 | 60860X1 | 760 | 5.05 | 1500 | 1800 | |||

| 380 | 38 | 2.1 | 166 | 233 | 61860 | 1000860 | 10.3 | 311 | 369 | 2 | 1400 | 1700 | |

| 420 | 56 | 3 | 269 | 370 | 61960M | 1000960H | 23.9 | 313 | 407 | 2.5 | 1300 | 1600 | |

| 460 | 50 | 4 | 285 | 405 | 16060 | 7000160 | 31.5 | 316 | 447 | 3 | 1200 | 1500 | |

| 460 | 74 | 4 | 355 | 500 | 6060 | 160 | 44.2 | 316 | 447 | 3 | 1200 | 1500 | |

| 540 | 85 | 5 | 465 | 670 | 6260 | 260 | 87.8 | 320 | 520 | 4 | 1000 | 1300 | |

| 620 | 109 | 7.5 | 593 | 886 | 6320 | 320 | 169 | 332 | 588 | 6 | 800 | 1000 | |

| 320 | 400 | 38 | 2.1 | 168 | 244 | 61864 | 1000864 | 10.8 | 331 | 389 | 2 | 1300 | 1600 |

| 440 | 56 | 3 | 275 | 392 | 61964 | 1000964 | 25.3 | 333 | 427 | 2.5 | 1200 | 1500 | |

| 480 | 50 | 4 | 293 | 430 | 16064 | 7000164 | 33.2 | 336 | 464 | 3 | 1100 | 1400 | |

| BounDary dimensious | Basic load ratings | Designations | Mass | installation dimension | Limiting speeds | ||||||||

| mm | kN | mm | r/min | ||||||||||

| d | D | B | rmin | Cr | Cor | Current | Original | kg | damin | Damax | ramax | Grease | Oil |

| 320 | 480 | 74 | 4 | 390 | 570 | 6064 | 164 | 46.5 | 336 | 464 | 3 | 1100 | 1400 |

| 580 | 92 | 5 | 530 | 805 | 6264 | 264 | 111 | 340 | 560 | 4 | 950 | 1200 | |

| 340 | 420 | 38 | 2.1 | 175 | 265 | 61868 | 1000868 | 11.5 | 351 | 409 | 2 | 1200 | 1500 |

| 460 | 56 | 3 | 292 | 418 | 61968 | 1000968 | 26.6 | 353 | 447 | 2.5 | 1100 | 1400 | |

| 520 | 57 | 4 | 345 | 520 | 16068 | 7000168 | 45 | 356 | 507 | 3 | 1000 | 1300 | |

| 520 | 82 | 5 | 440 | 660 | 6068 | 168 | 62.3 | 360 | 500 | 4 | 1000 | 1300 | |

| 620 | 92 | 6 | 530 | 820 | 6268 | 268 | 129 | 364 | 596 | 5 | 900 | 1100 | |

| 360 | 440 | 38 | 2.1 | 192 | 290 | 61872 | 1000872 | 11.8 | 371 | 429 | 2 | 1100 | 1400 |

| 480 | 56 | 3 | 280 | 425 | 61972 | 1000972 | 27.9 | 373 | 467 | 2.5 | 1100 | 1400 | |

| 540 | 57 | 4 | 351 | 550 | 16072 | 7000172 | 49 | 376 | 527 | 3 | 1000 | 1300 | |

| 540 | 82 | 5 | 460 | 720 | 6072 | 172 | 65.3 | 380 | 520 | 4 | 1000 | 1300 | |

| 550 | 85 | 5 | 460 | 720 | 61072X3 | 872 | 72.6 | 380 | 530 | 4 | 1000 | 1300 | |

| 650 | 95 | 6 | 555 | 905 | 6272 | 272 | 145 | 384 | 626 | 4 | 750 | 950 | |

| 380 | 480 | 46 | 2.1 | 238 | 375 | 61876 | 1000876 | 19.5 | 391 | 469 | 2 | 1000 | 1300 |

| 520 | 44 | 3 | 256 | 390 | 16976 | 7000976 | 30.5 | 1000 | 1300 | ||||

| 520 | 65 | 4 | 325 | 510 | 61976 | 1000976 | 40 | 396 | 504 | 3 | 1000 | 1300 | |

| 560 | 57 | 4 | 377 | 620 | 16076 | 7000176 | 51 | 950 | 1200 | ||||

| 560 | 82 | 5 | 455 | 725 | 6076 | 176 | 68 | 404 | 656 | 5 | 950 | 1200 | |

| 400 | 500 | 46 | 2.1 | 241 | 390 | 61880 | 1000880 | 20.5 | 411 | 489 | 2 | 1000 | 1300 |

| 540 | 65 | 4 | 335 | 540 | 61980 | 1000980 | 42 | 416 | 524 | 3 | 950 | 1200 | |

| 600 | 90 | 5 | 510 | 825 | 6080 | 180 | 88.4 | 420 | 580 | 4 | 900 | 1100 | |

| 420 | 520 | 46 | 2.1 | 245 | 410 | 61884 | 1000884 | 21.4 | 431 | 509 | 2 | 950 | 1200 |

| 560 | 65 | 4 | 340 | 570 | 61984 | 1000984 | 43.6 | 436 | 544 | 3 | 900 | 1100 | |

| 620 | 90 | 5 | 530 | 895 | 6084 | 184 | 92.2 | 440 | 600 | 4 | 900 | 1100 | |

| 440 | 540 | 46 | 2.1 | 249 | 425 | 61888 | 1000888 | 22.3 | 451 | 529 | 2 | 900 | 1100 |

| 600 | 74 | 4 | 395 | 680 | 61988F3 | 1000988 | 60.2 | 456 | 584 | 3 | 900 | 1100 | |

| 650 | 94 | 6 | 550 | 965 | 6088 | 188 | 106 | 460 | 630 | 4 | 850 | 1000 | |

| BounDary dimensious | Basic load ratings | Designations | Mass | installation dimension | Limiting speeds | ||||||||

| mm | kN | Current | Original | kg | mm | r/min | |||||||

| d | D | B | rmin | Cr | Cor | Current | Original | damin | Damax | ramax | Grease | Oil | |

| 460 | 580 | 56 | 3 | 310 | 550 | 61892 | 1000892 | 34.3 | 473 | 567 | 2.5 | 900 | 1100 |

| 620 | 74 | 4 | 405 | 720 | 61992 | 1000992 | 62.6 | 476 | 604 | 3 | 850 | 1000 | |

| 680 | 100 | 6 | 605 | 1080 | 6092 | 192 | 123 | 480 | 660 | 4 | 800 | 950 | |

| 480 | 600 | 56 | 3 | 315 | 575 | 61896 | 1000896 | 35.4 | 493 | 587 | 2.5 | 850 | 1000 |

| 650 | 78 | 5 | 450 | 815 | 61996 | 1000996 | 73.5 | 500 | 630 | 4 | 800 | 950 | |

| 700 | 100 | 6 | 605 | 1090 | 6096 | 196 | 127 | 500 | 680 | 4 | 750 | 900 | |

| 500 | 620 | 56 | 3 | 320 | 600 | 618/500 | 10008/500 | 37.2 | 513 | 607 | 2.5 | 800 | 950 |

| 670 | 78 | 5 | 460 | 865 | 619/500 | 10009/500 | 82 | 520 | 650 | 4 | 750 | 900 | |

| 720 | 100 | 6 | 630 | 1170 | 60/500 | 1/500 | 131 | 524 | 696 | 5 | 750 | 900 | |

| 530 | 650 | 56 | 3 | 325 | 625 | 618/530 | 10008/530 | 39.8 | 543 | 637 | 2.5 | 750 | 900 |

| 710 | 82 | 5 | 455 | 870 | 619/530 | 10009/530 | 89.8 | 550 | 690 | 4 | 750 | 900 | |

| 780 | 112 | 6 | 680 | 1300 | 60/530 | 1/530 | 184 | 554 | 756 | 5 | 700 | 850 | |

| 560 | 680 | 56 | 3 | 330 | 650 | 618/560 | 10008/560 | 41.5 | 573 | 667 | 2.5 | 700 | 850 |

| 750 | 85 | 5 | 525 | 1040 | 619/560 | 10009/560 | 105 | 580 | 730 | 4 | 670 | 800 | |

| 600 | 730 | 60 | 3 | 355 | 735 | 618/600 | 10008/600 | 50.9 | 613 | 717 | 2.5 | 670 | 800 |

| 800 | 90 | 5 | 550 | 1160 | 619/600 | 10009/600 | 120 | 620 | 780 | 4 | 630 | 750 | |

| 870 | 118 | 6 | 790 | 1640 | 60/600 | 1/600 | 236 | 624 | 846 | 5 | 600 | 700 | |

| 630 | 780 | 69 | 4 | 420 | 890 | 618/630 | 10008/630 | 71.3 | 646 | 767 | 3 | 630 | 750 |

| 850 | 100 | 6 | 625 | 1350 | 619/630 | 10009/630 | 163 | 654 | 826 | 5 | 600 | 700 | |

| 920 | 128 | 7.5 | 750 | 1620 | 60/630N1 | 1/630K | 285 | 662 | 888 | 6 | 560 | 670 | |

| 670 | 820 | 69 | 4 | 435 | 965 | 618/670 | 10008/670 | 75.4 | 686 | 807 | 3 | 560 | 670 |

| 900 | 103 | 6 | 675 | 1460 | 619/670 | 10009/670 | 181 | 694 | 876 | 5 | 530 | 630 | |

| 980 | 136 | 7.5 | 765 | 1730 | 60/670 | 1/670 | 351 | 702 | 948 | 6 | 500 | 600 | |

| 710 | 870 | 74 | 4 | 480 | 1100 | 618/710 | 10008/710 | 92.6 | 726 | 854 | 3 | 530 | 630 |

| 950 | 106 | 6 | 715 | 1640 | 619/710 | 10009/710 | 220 | 734 | 926 | 5 | 500 | 600 | |

| 1030 | 140 | 7.5 | 1020 | 2310 | 60/710 | 1/710 | 386 | 742 | 998 | 6 | 480 | 560 | |

| BounDary dimensious | Basic load ratings | Designations | Mass | installation dimension | Limiting speeds | ||||||||

| mm | kN | mm | r/min | ||||||||||

| D | D | B | rmin | Cr | Cor | Current | Original | kg | damin | Damax | ramax | Grease | Oil |

| 750 | 920 | 78 | 5 | 525 | 1260 | 618/750 | 10008/750 | 110 | 770 | 900 | 4 | 500 | 600 |

| 1000 | 112 | 6 | 785 | 1840 | 619/750 | 10009/750 | 245 | 774 | 976 | 5 | 480 | 560 | |

| 1090 | 150 | 7.5 | 995 | 2360 | 60/750 | 1/750 | 485 | 782 | 1058 | 6 | 450 | 530 | |

| 800 | 980 | 82 | 5 | 530 | 1310 | 618/800 | 10008/800 | 132 | 820 | 960 | 4 | 450 | 530 |

| 1060 | 115 | 6 | 825 | 2050 | 619/800 | 10009/800 | 275 | 824 | 1036 | 5 | 430 | 500 | |

| 850 | 1150 | 110 | 10 | 1270 | 3860 | 618/850X3 | 3707/850 | 140 | 904 | 1096 | 10 | 430 | 500 |

| 900 | 1090 | 85 | 5 | 618 | 1532 | 618/900 | 10008/900 | 160 | 920 | 1070 | 4 | 380 | 450 |

| 1000 | 1220 | 100 | 6 | 637 | 1250 | 618/1000 | 10008/1000 | 245 | 1024 | 1196 | 5 | 340 | 400 |

| 1060 | 1280 | 100 | 6 | 728 | 1500 | 618/1060 | 10008/1060 | 260 | 1084 | 1256 | 5 | 300 | 360 |

| 1120 | 1360 | 106 | 6 | 765 | 1960 | 618/1120 | 10008/1120 | 315 | 1144 | 1336 | 5 | - | - |

| 1140 | 1380 | 106 | 6 | 858 | 2390 | 618/1140 | 10008/1140 | 324 | - | - | |||

| 1180 | 1420 | 106 | 6 | 792 | 2210 | 618/1180 | 10008/1180 | 342 | 1204 | 1396 | 5 | 260 | 320 |

| 1250 | 1500 | 112 | 3 | 927 | 2670 | 618/1250 | 10008/1250 | 178 | 1274 | 1476 | 5 | ||

| 1320 | 1600 | 122 | 6 | 956 | 2350 | 618/1320 | 10008/1320 | 500 | 1344 | 1576 | 5 | 190 | 240 |

| 1400 | 1700 | 132 | 7.5 | 1120 | 2750 | 618/1400 | 10008/1400 | 615 | 1432 | 1688 | 6 | 190 | 240 |

YOU MAY LIKE

VIEW MOREAngular Contact Thrust Ball Bearings

VIEW MOREAngular Contact Thrust Ball Bearings VIEW MORELarge Thrust Ball Bearing

VIEW MORELarge Thrust Ball Bearing VIEW MORE4 Point Angular Contact Ball Bearing

VIEW MORE4 Point Angular Contact Ball Bearing VIEW MOREAngular Contact Ball Bearings Single Row

VIEW MOREAngular Contact Ball Bearings Single Row VIEW MOREAngular Contact Thrust Ball Bearing

VIEW MOREAngular Contact Thrust Ball Bearing VIEW MORE4 Point Contact Ball Bearing

VIEW MORE4 Point Contact Ball Bearing VIEW MOREThrust Ball Bearing

VIEW MOREThrust Ball Bearing VIEW MORESingle-Direction Angular Contact Thrust Ball Bearing

VIEW MORESingle-Direction Angular Contact Thrust Ball Bearing