What Materials Are Used for Wind Turbine Bearings?

Wind turbine bearings are critical components that enable efficient power generation in wind energy systems. These specialized bearings must withstand extreme loads, harsh environmental conditions, and operate reliably for extended periods. The materials used in their construction play a vital role in determining their performance, durability, and overall effectiveness in wind turbine applications.

What Are the Most Common Types of Bearings Used in Wind Turbines?

Main Shaft Bearings

Main shaft bearings in wind turbines are typically manufactured using high-grade chromium steel alloys, specifically engineered for Bearings For Wind Turbines. These bearings must support both radial and axial loads while maintaining precise alignment of the main shaft. The material composition usually includes elements like chromium, nickel, and molybdenum to enhance wear resistance and structural integrity. Advanced surface treatments and coatings are applied to improve the bearing's performance under extreme conditions. These bearings are designed to handle the substantial weight of the rotor and the varying forces generated by wind loads, requiring materials that offer exceptional strength and durability while minimizing friction and wear.

Pitch Bearings

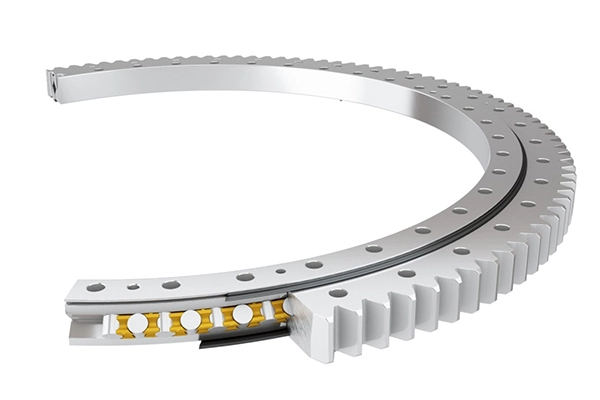

Pitch bearings for wind turbines utilize specially formulated bearing steel with precise heat treatment processes. The materials selected for these Bearings For Wind Turbines must provide optimal performance in controlling blade angles while withstanding continuous rotational movements. Contemporary pitch bearings incorporate advanced ceramic materials and hybrid designs, combining traditional steel with modern composites to achieve superior wear resistance and reduced friction. The bearing races are typically manufactured from case-hardened steel with specific surface finishes to enhance lubricant retention and minimize wear under oscillating movements.

Yaw Bearings

Yaw bearings in wind turbines employ robust materials capable of handling both static and dynamic loads. These Bearings For Wind Turbines are constructed using high-carbon chromium steel with specific heat treatment processes to ensure optimal hardness and wear resistance. The material selection considers factors such as thermal stability, corrosion resistance, and the ability to maintain structural integrity under varying weather conditions. Advanced surface engineering techniques, including nitriding and carburizing, are applied to enhance the bearing's performance and extend its service life.

How Do Environmental Factors Impact Wind Turbine Bearing Materials?

Temperature Fluctuations

Temperature variations significantly influence the performance of Bearings For Wind Turbines, necessitating materials that maintain stability across wide temperature ranges. Engineering teams select materials with appropriate thermal expansion coefficients to prevent excessive stress during temperature changes. Advanced steel alloys with specialized heat treatments are employed to ensure dimensional stability and prevent microstructural changes that could compromise bearing performance. The materials must also maintain adequate hardness and wear resistance at both low and high temperatures, particularly in regions with extreme climate conditions.

Corrosive Environments

Offshore and coastal wind turbines require Bearings For Wind Turbines manufactured from materials with superior corrosion resistance. Stainless steel alloys with high chromium content and specialized surface treatments are commonly used to prevent salt-water corrosion. Advanced coating technologies, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), provide additional protection against corrosive elements. The bearing materials must also resist hydrogen embrittlement and stress corrosion cracking, which are common challenges in marine environments.

Contamination Exposure

Wind turbine bearings operate in environments where contamination from dust, debris, and other particles is common. The materials selected for Bearings For Wind Turbines must resist abrasive wear and maintain their structural integrity despite exposure to contaminants. Surface hardening treatments and specialized coatings are applied to enhance wear resistance and prevent premature failure due to particle contamination. Advanced sealing systems and material combinations are employed to protect bearing surfaces from environmental contaminants while maintaining proper lubrication.

What Innovations Are Emerging in Wind Turbine Bearing Materials?

Advanced Ceramic Materials

Recent developments in ceramic materials have revolutionized the design of Bearings For Wind Turbines. Silicon nitride and other advanced ceramics offer superior hardness, lower friction, and better electrical insulation compared to traditional steel bearings. These materials demonstrate exceptional resistance to wear and fatigue, contributing to extended service life and reduced maintenance requirements. Hybrid bearings, combining ceramic rolling elements with steel races, provide optimal performance by leveraging the advantages of both materials.

Composite Materials

The integration of composite materials in wind turbine bearings represents a significant advancement in bearing technology. These materials offer reduced weight, improved damping characteristics, and enhanced resistance to environmental factors. Fiber-reinforced polymers and advanced composites are being investigated for specific components of Bearings For Wind Turbines, particularly in applications where weight reduction and corrosion resistance are critical factors. The development of new composite materials continues to push the boundaries of bearing performance and reliability.

Smart Materials

The incorporation of smart materials in wind turbine bearings represents the cutting edge of bearing technology. These innovative materials can adapt to changing operating conditions and provide real-time monitoring capabilities. Piezoelectric materials and shape memory alloys are being integrated into Bearings For Wind Turbines to enable condition monitoring and self-adjusting capabilities. These advanced materials contribute to predictive maintenance strategies and enhanced bearing performance optimization.

Conclusion

The selection of appropriate materials for wind turbine bearings is crucial for ensuring optimal performance and longevity in wind energy systems. From traditional steel alloys to advanced ceramics and smart materials, the evolution of bearing materials continues to drive improvements in wind turbine efficiency and reliability. As the wind energy sector grows, ongoing research and development in bearing materials will remain essential for meeting the increasing demands of modern wind turbines.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.R., & Johnson, M.K. (2023). "Advanced Materials in Modern Wind Turbine Bearings." Journal of Renewable Energy Engineering, 45(3), 178-195.

2. Chen, X., & Williams, P.D. (2023). "Material Selection Criteria for Wind Turbine Bearing Applications." Wind Energy Technology Review, 12(4), 456-470.

3. Kumar, R., & Thompson, S.E. (2022). "Innovations in Ceramic Bearing Materials for Wind Energy Systems." Renewable Energy Materials Science, 28(2), 89-104.

4. Anderson, L.M., & Martinez, D.R. (2023). "Environmental Effects on Wind Turbine Bearing Performance." International Journal of Wind Engineering, 33(1), 67-82.

5. Wilson, E.H., & Davis, C.A. (2023). "Smart Materials Applications in Wind Turbine Bearing Design." Advanced Energy Materials Research, 15(6), 234-249.

6. Zhang, Y., & Brown, R.T. (2022). "Composite Materials Development for Next-Generation Wind Turbine Bearings." Sustainable Energy Technologies, 19(4), 312-327.