Are Tapered Roller Bearings Better Than Ball Bearings?

In the world of mechanical engineering and industrial applications, the choice of bearing type can significantly impact the performance, longevity, and efficiency of machinery. Two popular options that often come under comparison are tapered roller bearings and ball bearings. Each has its unique characteristics, advantages, and ideal applications. This blog post delves into the question: Are tapered rollers better than ball bearings? To answer this, we'll explore the key differences, applications, and considerations for both types of bearings.

What are the main differences between tapered roller bearings and ball bearings?

Tapered roller bearings and ball bearings are two distinct types of rolling-element bearings, each with its own set of characteristics that make them suitable for different applications. Understanding these differences is crucial for engineers and designers when selecting the appropriate bearing for a specific use case.

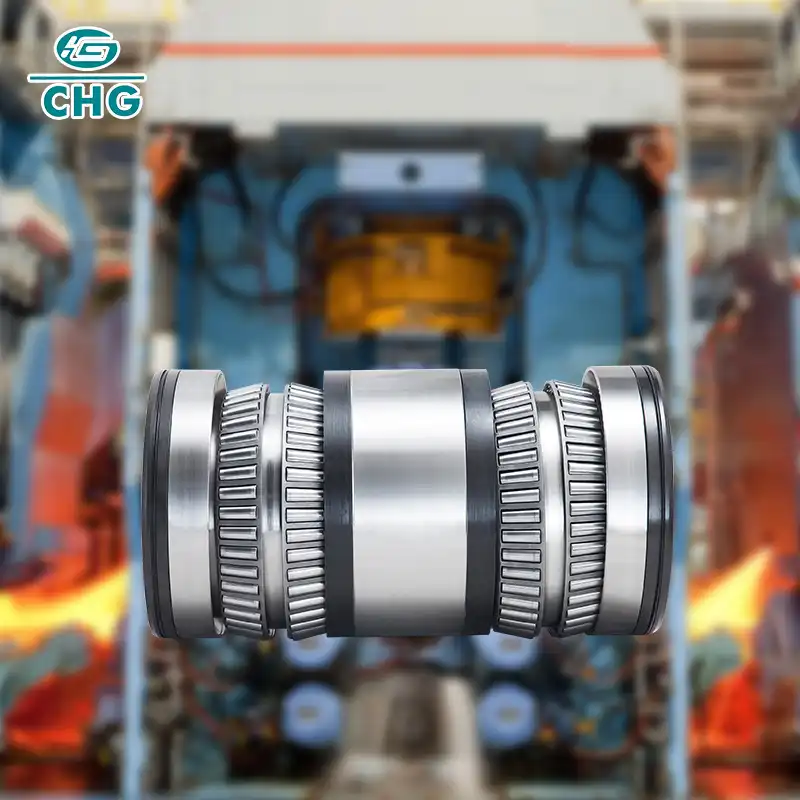

Tapered roller bearings, as the name suggests, are cone-shaped rolling elements that sit between two races (inner and outer rings). The tapered design allows for a larger contact area between the roller and the races, which provides several advantages:

1. Higher load capacity: Tapered roller bearings can handle greater radial and axial loads compared to ball bearings of similar size. This is due to the increased contact area, which distributes the load more evenly across the bearing surface.

2. Better alignment: The tapered design allows for some self-alignment, which can help compensate for minor misalignments in the system.

3. Reduced sliding: The rolling motion of tapered roller bearings involves less sliding than ball bearings, which can lead to reduced friction and wear in certain applications.

4. Separable components: Tapered roller bearings typically have separable inner and outer races, which can simplify installation and maintenance in some cases.

On the other hand, ball bearings consist of spherical balls that roll between inner and outer races. They offer their own set of advantages:

1. Lower friction: Ball bearings generally have lower friction than tapered roller bearings, especially at high speeds. This makes them ideal for applications where minimizing energy loss is crucial.

2. Higher speed capability: Due to their lower friction and reduced heat generation, ball bearings can typically operate at higher speeds than tapered roller bearings.

3. Compact design: Ball bearings are often more compact than tapered roller bearings for a given load capacity, which can be advantageous in space-constrained applications.

4. Versatility: Ball bearings come in a wide variety of designs and sizes, making them suitable for a broad range of applications.

5. Lower cost: In general, ball bearings are less expensive to manufacture than tapered roller bearings, which can make them more cost-effective for certain applications.

The choice between tapered rollers and ball bearings often comes down to the specific requirements of the application. Factors such as load type (radial, axial, or combined), speed, space constraints, and operating environment all play a role in determining which bearing type is more suitable.

How do tapered roller bearings perform in high-load applications compared to ball bearings?

When it comes to high-load applications, tapered rollers generally outperform ball bearings. This superior performance in load-bearing capacity is one of the primary reasons why tapered roller bearings are often preferred in heavy-duty industrial machinery, automotive components, and other applications where significant forces are at play.

The key to the high-load performance of tapered roller bearings lies in their geometry and contact mechanics. The tapered shape of the rollers allows for a larger contact area between the roller and the races compared to the point contact of ball bearings. This increased contact area distributes the load over a greater surface, resulting in several advantages:

1. Higher load capacity: Tapered roller bearings can handle significantly higher radial and axial loads than ball bearings of comparable size. This makes them ideal for applications such as wheel bearings in heavy vehicles, gearboxes in industrial machinery, and rotary tables in machine tools.

2. Reduced stress concentration: The larger contact area helps to reduce stress concentrations, which can lead to improved fatigue life and reduced risk of premature failure under heavy loads.

3. Better shock resistance: Tapered roller bearings are generally better at handling shock loads and impact forces due to their ability to distribute these forces more evenly.

4. Improved stiffness: The design of tapered roller bearings often results in greater overall system stiffness, which can be crucial in applications where precision and minimal deflection are required under load.

5. Combined load handling: Tapered roller bearings excel at handling combined radial and axial loads, making them suitable for applications where forces act in multiple directions simultaneously.

However, it's important to note that the superior load-bearing capacity of tapered rollers comes with some trade-offs:

1. Increased friction: Due to the larger contact area and the sliding component of the rolling motion, tapered roller bearings typically generate more friction than ball bearings, especially at higher speeds.

2. Heat generation: The increased friction can lead to greater heat generation, which may require additional cooling or lubrication in some high-speed, high-load applications.

3. Speed limitations: While tapered roller bearings excel in load capacity, they generally have lower speed limits compared to ball bearings due to the higher friction and heat generation.

4. Complexity: Tapered roller bearings are more complex in design and typically require more precise setup and maintenance than ball bearings.

In contrast, ball bearings, while not as capable in extreme load situations, offer advantages in high-speed, low-friction applications. They are often preferred in scenarios where minimizing energy loss and heat generation is crucial, such as in electric motors, turbines, and precision instruments.

When selecting between tapered roller bearings and ball bearings for high-load applications, engineers must carefully consider the specific requirements of the system. Factors such as the magnitude and direction of loads, operating speeds, space constraints, and maintenance requirements all play a role in determining the optimal bearing choice.

In some cases, a combination of both bearing types may be used within a single application to leverage the strengths of each. For example, an automotive transmission might use tapered roller bearings for high-load gear supports and ball bearings for high-speed shafts.

What factors should be considered when choosing between tapered roller bearings and ball bearings?

Selecting the appropriate bearing type for a specific application is a critical decision that can significantly impact the performance, reliability, and efficiency of a mechanical system. When choosing between tapered roller bearings and ball bearings, several key factors should be carefully considered to ensure the optimal solution is implemented.

1. Load characteristics:

- Type of load: Consider whether the application primarily involves radial loads, axial loads, or a combination of both. Tapered roller bearings excel in handling combined loads, while ball bearings are often better suited for applications with predominantly radial loads.

- Load magnitude: Assess the maximum and average loads the bearing will experience. Tapered roller bearings generally have higher load capacities and are better suited for heavy-duty applications.

- Dynamic vs. static loads: Evaluate whether the loads are primarily static or dynamic. Tapered rollers often perform better under heavy, fluctuating loads.

2. Speed requirements:

- Operating speed range: Determine the typical and maximum operating speeds of the application. Ball bearings generally have higher speed capabilities due to their lower friction characteristics.

- Speed variations: Consider whether the application involves frequent starts, stops, or speed changes. Tapered roller bearings may be more suitable for applications with frequent speed variations due to their robustness.

3. Precision and stiffness:

- Accuracy requirements: Assess the level of precision needed in the application. While both bearing types can be manufactured to high precision standards, ball bearings are often preferred in ultra-precision applications.

- System stiffness: Consider the overall stiffness requirements of the system. Tapered roller bearings typically provide greater stiffness, which can be crucial in machine tool applications.

4. Space constraints:

- Available space: Evaluate the space available for the bearing installation. Ball bearings are generally more compact, making them suitable for applications with tight space restrictions.

- Shaft and housing dimensions: Consider the existing shaft and housing dimensions, as these may influence the choice between tapered rollers and ball bearings.

5. Environmental factors:

- Operating temperature: Assess the temperature range in which the bearing will operate. Both bearing types have different temperature limitations and heat generation characteristics.

- Contamination: Consider the potential for contamination in the operating environment. Tapered roller bearings may be more tolerant of some types of contamination due to their larger contact area.

- Lubrication requirements: Evaluate the lubrication needs and available lubrication systems. Tapered roller bearings often require more precise lubrication due to their sliding component.

6. Maintenance and serviceability:

- Maintenance frequency: Consider the desired maintenance intervals and accessibility of the bearing. Tapered roller bearings may require more frequent maintenance but are often easier to inspect and adjust.

- Serviceability: Assess whether easy disassembly and reassembly are important. Tapered roller bearings with separable components can offer advantages in this regard.

7. Cost considerations:

- Initial cost: Compare the upfront costs of both bearing types. Ball bearings are generally less expensive to manufacture.

- Lifecycle cost: Consider the long-term costs, including maintenance, potential replacements, and energy consumption. The higher load capacity of tapered roller bearings may result in longer service life in some applications.

8. Specific application requirements:

- Industry standards: Check if there are any industry-specific standards or preferences that may influence the bearing choice.

- Noise and vibration: Consider the noise and vibration requirements of the application. Ball bearings often produce less noise at high speeds.

- Misalignment tolerance: Assess whether the application may involve misalignment issues. Tapered roller bearings generally have better misalignment tolerance.

9. Supplier and availability:

- Availability: Consider the availability of both bearing types in the required sizes and specifications.

- Supplier expertise: Evaluate the expertise and support offered by bearing suppliers for each type.

10. Future-proofing:

- Scalability: Consider potential future changes in load or speed requirements and choose a bearing type that can accommodate potential upgrades.

- Compatibility: Assess the compatibility of the chosen bearing type with other components in the system and potential future modifications.

By carefully considering these factors, engineers and designers can make an informed decision when choosing between tapered rollers and ball bearings. It's important to remember that in many cases, the optimal solution may involve a combination of both bearing types within a single system, leveraging the strengths of each to meet the specific requirements of different components.

In conclusion, while tapered roller bearings offer advantages in high-load capacity, combined load handling, and stiffness, ball bearings excel in high-speed, low-friction applications and compact designs. The choice between the two depends on a thorough analysis of the application's specific requirements and constraints. By carefully weighing the factors discussed in this blog post, engineers can select the most appropriate bearing type to ensure optimal performance, reliability, and efficiency in their mechanical systems.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. SKF Group. (2021). "Bearing selection process." SKF.com.

2. Timken Company. (2020). "Tapered Roller Bearing Catalog." Timken.com.

3. NSK Ltd. (2019). "Rolling Bearings: A Handbook for Design Engineers." NSK Global.

4. Schaeffler Technologies AG & Co. KG. (2018). "Technical Pocket Guide." Schaeffler.com.

5. American Bearing Manufacturers Association. (2017). "Load Ratings & Fatigue Life for Ball Bearings." ABMA.com.

6. Harris, T. A., & Kotzalas, M. N. (2006). "Essential Concepts of Bearing Technology." CRC Press.

7. Hamrock, B. J., & Anderson, W. J. (1983). "Rolling-Element Bearings." NASA Technical Reports Server.

8. NTN Corporation. (2022). "Ball and Roller Bearings: Selection Guide." NTN Global.

9. FAG Bearings. (2020). "Rolling Bearing Damage: Recognition of damage and bearing inspection." Schaeffler.com.

10. SKF Group. (2018). "Bearing self-study guide." SKF.com.