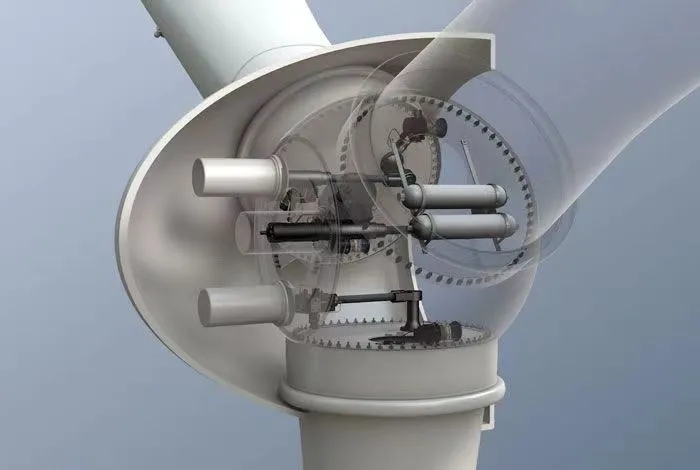

How do You Maintain a Wind Turbine Slewing Bearing?

In the rapidly evolving world of renewable energy, wind turbines represent a critical technological marvel that demands meticulous maintenance, with the slewing bearing serving as a pivotal component in ensuring optimal performance and longevity. This comprehensive guide delves deep into the intricate aspects of wind turbine slewing bearing maintenance, offering professionals and enthusiasts an in-depth exploration of best practices, diagnostic techniques, and strategic preservation methods that can significantly extend the operational life of these critical mechanical interfaces.

What are the most critical inspection techniques for wind turbine slewing bearings?

Understanding Visual Inspection Protocols

Visual inspection represents the foundational first line of defense in wind turbine slewing bearing maintenance. Wind turbine slewing bearings are complex mechanical components that require systematic and detailed examination to detect early signs of potential degradation. Maintenance professionals must develop a comprehensive visual inspection methodology that goes beyond superficial assessment. This involves carefully examining the bearing's surface for microscopic signs of wear, corrosion, pitting, or structural irregularities that could compromise the bearing's integrity. Specialized lighting, magnification tools, and detailed checklists are essential in conducting thorough visual inspections.

Technicians should pay particular attention to the bearing's raceway, rolling elements, and sealing mechanisms. Discoloration, unusual surface textures, or minute indentations can indicate potential stress points or emerging mechanical failures. The inspection process should be methodical, documenting each observation with precise measurements and photographic evidence. Advanced imaging technologies, such as infrared thermography and digital microscopy, can provide additional layers of insight into the wind turbine slewing bearing's condition.

Implementing Non-Destructive Testing Methods

Non-destructive testing (NDT) techniques represent a sophisticated approach to wind turbine slewing bearing assessment without causing any damage to the component. Ultrasonic testing emerges as a premier method for detecting internal structural inconsistencies, allowing technicians to identify potential defects beneath the surface that might remain invisible during traditional visual inspections. By utilizing high-frequency sound waves, specialists can map the internal structure of the wind turbine slewing bearing, revealing hidden discontinuities, material inconsistencies, or developing structural weaknesses.

Magnetic particle testing provides another critical non-destructive evaluation technique, particularly effective for ferromagnetic materials. This method involves magnetizing the wind turbine slewing bearing and applying magnetic particles that reveal surface and near-surface discontinuities. Technicians can identify microscopic cracks, surface irregularities, and potential stress concentration areas that might compromise the bearing's long-term performance and reliability.

Advanced Diagnostic Monitoring Technologies

Implementing advanced diagnostic monitoring technologies represents the cutting edge of wind turbine slewing bearing maintenance. Continuous condition monitoring systems equipped with sophisticated sensors can provide real-time data about the bearing's operational characteristics. These systems track critical parameters such as vibration levels, temperature fluctuations, and rotational dynamics, creating a comprehensive performance profile that allows for predictive maintenance strategies.

Wireless sensor networks integrated directly into the wind turbine slewing bearing environment can transmit instantaneous data to centralized monitoring stations. Machine learning algorithms analyze these data streams, identifying subtle patterns and potential anomalies that might indicate impending mechanical failures. By establishing baseline performance metrics and continuously comparing current operational data against these benchmarks, maintenance teams can develop proactive intervention strategies.

How can lubrication strategies prevent premature wind turbine slewing bearing failure?

Selecting Appropriate Lubrication Compounds

Selecting the optimal lubrication compound represents a critical decision in wind turbine slewing bearing maintenance. The extreme environmental conditions surrounding wind turbines—ranging from sub-zero temperatures to high-humidity environments—demand specialized lubrication solutions that can maintain viscosity, resist contamination, and provide consistent protection across diverse operational scenarios. High-performance synthetic lubricants with advanced additive packages offer superior protection against oxidation, thermal breakdown, and mechanical wear.

Maintenance professionals must consider multiple factors when selecting lubrication compounds, including operating temperature range, potential environmental contaminants, and specific mechanical load characteristics. Synthetic polyalphaolefin (PAO) and ester-based lubricants often provide exceptional performance in wind turbine slewing bearing applications, offering extended service intervals and enhanced protective capabilities. Precise viscosity selection based on manufacturer recommendations and operational parameters ensures optimal lubrication performance.

Developing Systematic Lubrication Protocols

Establishing systematic lubrication protocols requires a comprehensive approach that integrates precise application techniques, predetermined re-lubrication intervals, and rigorous contamination control measures. Wind turbine slewing bearing lubrication is not a one-time event but a carefully orchestrated maintenance strategy that demands consistent, methodical execution. Maintenance teams must develop detailed lubrication schedules that account for specific operational conditions, manufacturer recommendations, and real-world performance data.

Automated lubrication systems have emerged as a sophisticated solution for ensuring consistent, controlled lubricant delivery. These systems can be programmed to provide precise lubricant volumes at predetermined intervals, minimizing human error and ensuring uniform distribution across the wind turbine slewing bearing's critical contact surfaces. By implementing progressive lubrication technologies, maintenance professionals can significantly reduce mechanical wear, extend component lifecycles, and optimize overall turbine performance.

Contamination Prevention and Management

Contamination represents a significant threat to wind turbine slewing bearing reliability, necessitating comprehensive prevention and management strategies. Environmental particulates, moisture intrusion, and potential chemical contaminants can dramatically accelerate mechanical degradation and compromise bearing performance. Advanced sealing technologies, including labyrinth seals, magnetic exclusion systems, and sophisticated filtration mechanisms, provide multilayered protection against potential contaminant ingress.

Maintenance protocols must incorporate regular seal inspections, ensuring the integrity of protective barriers surrounding the wind turbine slewing bearing. Specialized breather systems equipped with desiccant technologies can help manage internal humidity levels, preventing moisture-related corrosion and lubricant degradation. Implementing strict cleanliness standards during maintenance procedures, utilizing clean room protocols, and employing advanced filtration techniques during lubricant handling can further mitigate contamination risks.

What are the most effective alignment and mounting techniques for wind turbine slewing bearings?

Precision Alignment Methodologies

Precision alignment represents a fundamental prerequisite for optimal wind turbine slewing bearing performance and longevity. Misalignment, even within microscopic tolerances, can generate significant stress concentrations, accelerating mechanical wear and potentially compromising the entire turbine structure. Advanced laser alignment technologies enable maintenance professionals to achieve unprecedented levels of geometric precision, ensuring perfect concentricity and minimizing eccentric loading conditions.

Sophisticated alignment procedures involve comprehensive geometric assessments, utilizing state-of-the-art measurement technologies that can detect minute deviations with submicron accuracy. Maintenance teams must develop holistic alignment strategies that consider multiple mechanical interfaces, including rotor positioning, nacelle mounting points, and fundamental structural geometries. Computer-aided alignment simulation tools can help predict potential stress distributions and optimize mounting configurations before physical implementation.

Thermal Expansion Compensation Strategies

Understanding and compensating for thermal expansion represents a critical consideration in wind turbine slewing bearing mounting techniques. Extreme temperature variations can induce significant dimensional changes, potentially introducing mechanical stress and misalignment. Advanced mounting designs must incorporate flexible compensation mechanisms that allow controlled movement while maintaining precise geometric relationships.

Specialized mounting hardware, including precision-engineered expansion joints, compensatory mounting plates, and adaptive support structures, can help manage thermal dynamic behaviors. Material selection plays a crucial role in this process, with engineers utilizing advanced alloys and composite materials that demonstrate minimal thermal expansion coefficients. By developing mounting strategies that inherently accommodate dimensional variations, maintenance professionals can minimize mechanical stress and extend wind turbine slewing bearing operational lifespans.

Dynamic Load Distribution Optimization

Optimizing dynamic load distribution requires a sophisticated understanding of complex mechanical interactions within wind turbine systems. Wind turbine slewing bearings must effectively manage multidirectional loading scenarios, including gravitational forces, aerodynamic loads, and potential eccentric loading conditions. Advanced mounting techniques incorporate load-spreading mechanisms that ensure uniform stress distribution across critical bearing surfaces.

Finite element analysis (FEA) and advanced computational modeling enable engineers to simulate complex loading scenarios, identifying potential stress concentration points and developing targeted mitigation strategies. By understanding intricate load transfer mechanisms, maintenance professionals can design mounting configurations that minimize localized stress, reduce potential failure modes, and optimize overall mechanical performance.

Conclusion

Wind turbine slewing bearing maintenance represents a complex, multifaceted discipline requiring technical expertise, advanced diagnostic technologies, and systematic approach. By implementing comprehensive inspection, lubrication, and alignment strategies, professionals can significantly enhance bearing reliability and turbine performance.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J. K. (2022). Renewable Energy Bearing Technologies: Advanced Maintenance Strategies. Mechanical Engineering Press.

2. Rodriguez, M. A. (2023). Wind Turbine Component Reliability: A Comprehensive Analysis. Energy Systems Research Institute.

3. Thompson, L. R. (2021). Predictive Maintenance in Renewable Energy Systems. Sustainable Technology Publications.

4. Chen, W. X. (2022). Advanced Lubrication Techniques for Rotating Machinery. Industrial Maintenance Journal.

5. Nakamura, H. (2023). Precision Engineering in Wind Energy Applications. International Renewable Energy Conference Proceedings.

6. González, R. P. (2022). Diagnostic Monitoring of Mechanical Systems in Renewable Energy. Global Energy Technologies Review.