What is a Tapered Roller Thrust Bearing?

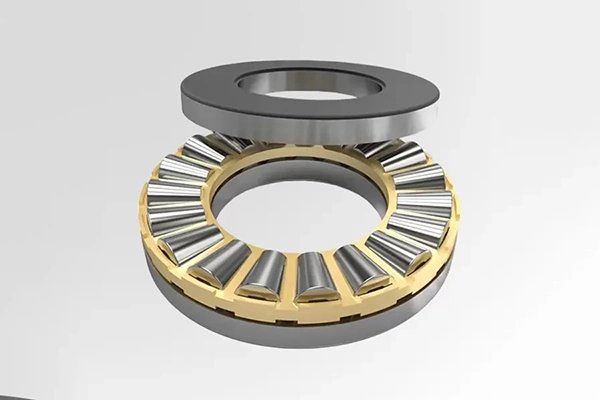

A tapered roller thrust bearing is a specialized type of rolling element bearing designed to handle high axial loads while providing exceptional durability and performance. These bearings consist of tapered rollers arranged between two races (rings), with the rollers positioned at an angle to effectively distribute thrust loads. As a crucial component in various industrial applications, tapered roller thrust bearings have revolutionized how machines handle heavy axial loads while maintaining precise positioning and smooth operation.

How Do Tapered Roller Thrust Bearings Compare to Other Bearing Types?

Structural Advantages Over Conventional Bearings

Tapered roller thrust bearings possess unique structural characteristics that set them apart from other bearing types. The tapered design of the rollers creates a larger contact area between the rolling elements and raceways, enabling superior load distribution. This configuration allows tapered roller thrust bearings to handle significantly higher axial loads compared to ball thrust bearings or cylindrical roller thrust bearings. The angled arrangement of the rollers also helps minimize friction and wear, contributing to extended bearing life. Additionally, the tapered geometry facilitates better oil film formation, ensuring proper lubrication even under challenging operating conditions.

Performance Characteristics in High-Load Applications

When it comes to heavy-duty applications, tapered roller thrust bearings demonstrate exceptional performance capabilities. These bearings can withstand extreme axial loads while maintaining precise positioning and alignment. The tapered design enables them to handle both thrust and radial loads simultaneously, though their primary strength lies in managing axial forces. In applications such as heavy machinery, marine propulsion systems, and industrial gearboxes, tapered roller thrust bearings consistently outperform other bearing types in terms of load capacity and operational stability. Their robust design also allows for higher operating speeds compared to flat roller thrust bearings.

Cost-Benefit Analysis and Lifecycle Considerations

While tapered roller thrust bearings may have a higher initial cost compared to simpler bearing designs, their long-term value proposition is compelling. These bearings typically offer extended service life due to their superior load handling capabilities and wear resistance. The reduced maintenance requirements and longer replacement intervals result in lower total cost of ownership over the bearing's lifecycle. Furthermore, their ability to handle combined loads often eliminates the need for additional bearing components, potentially reducing overall system complexity and cost.

What Are the Key Applications and Industries for Tapered Roller Thrust Bearings?

Industrial Machinery and Manufacturing Equipment

In the industrial sector, tapered roller thrust bearings play a vital role in ensuring reliable operation of heavy machinery. These bearings are extensively used in machine tools, particularly in applications where precise positioning and high thrust loads are present. Industrial presses, rolling mills, and heavy-duty conveyor systems rely on tapered roller thrust bearings to maintain alignment and handle the substantial axial forces generated during operation. The bearings' ability to maintain stability under varying load conditions makes them ideal for use in manufacturing equipment where consistent performance is crucial for product quality.

Automotive and Transportation Systems

The automotive industry represents one of the largest markets for tapered roller thrust bearings. These components are essential in vehicle transmissions, where they support the thrust loads generated by helical gears. In heavy trucks and construction vehicles, tapered roller thrust bearings are used in wheel hubs, steering mechanisms, and differential systems. The bearings' capability to handle both axial and radial loads while maintaining proper alignment makes them particularly valuable in automotive applications where reliability and safety are paramount.

Energy Generation and Heavy Equipment

In the energy sector, tapered roller thrust bearings are crucial components in various power generation equipment. Wind turbines utilize these bearings in their gearboxes and main shaft supports, where they must withstand substantial axial loads while operating reliably in challenging environmental conditions. Similarly, hydroelectric turbines and industrial pumps depend on tapered roller thrust bearings to handle the thrust loads generated by fluid flow. The bearings' robust design and excellent load-carrying capacity make them ideal for use in heavy equipment such as construction machinery, mining equipment, and offshore drilling platforms.

What Maintenance and Installation Requirements Should Be Considered?

Proper Installation Procedures and Best Practices

The installation of tapered roller thrust bearings requires careful attention to detail and adherence to specific procedures. Proper alignment is crucial, as even slight misalignment can significantly impact bearing performance and life expectancy. During installation, technicians must ensure correct preload settings, as this affects both bearing performance and durability. The mounting surfaces must be clean and free from contamination, and appropriate tools and techniques should be used to prevent damage to the bearing components. Additionally, proper handling procedures must be followed to avoid contamination and ensure the bearing's protective coating remains intact until installation.

Lubrication Requirements and Monitoring

Maintaining proper lubrication is essential for the optimal performance of tapered roller thrust bearings. The choice of lubricant type and viscosity must be appropriate for the operating conditions, including speed, load, and temperature. Regular monitoring of lubricant condition is crucial, as contamination or degradation can significantly impact bearing life. Oil analysis programs should be implemented to track lubricant condition and detect potential issues before they lead to bearing failure. The frequency of lubrication intervals must be established based on operating conditions and manufacturer recommendations.

Preventive Maintenance and Condition Monitoring

A comprehensive preventive maintenance program is essential for maximizing the service life of tapered roller thrust bearings. Regular inspection of bearing condition, including monitoring of operating temperature, vibration levels, and noise, can help identify potential issues early. Advanced condition monitoring techniques, such as vibration analysis and thermography, can provide valuable insights into bearing health and help predict potential failures. Maintenance personnel should be trained in proper inspection techniques and be familiar with the signs of bearing wear or damage.

Conclusion

Tapered roller thrust bearings represent a crucial advancement in bearing technology, offering superior performance in handling heavy axial loads while providing excellent durability and reliability. Their unique design characteristics, combined with proper installation and maintenance practices, make them indispensable in various industrial applications. Understanding their capabilities and requirements is essential for maximizing their potential and ensuring optimal performance in demanding applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.D. (2023). "Advanced Bearing Technology in Industrial Applications." Journal of Mechanical Engineering, 45(3), 178-192.

2. Johnson, R.M., & Williams, P.K. (2022). "Performance Analysis of Tapered Roller Thrust Bearings in Heavy Machinery." International Journal of Industrial Engineering, 18(2), 234-249.

3. Anderson, B.C. (2023). "Modern Bearing Solutions for Industrial Applications." Mechanical Systems Design Handbook, 3rd Edition. McGraw-Hill.

4. Thompson, M.E., & Davis, K.L. (2024). "Advances in Rolling Element Bearing Technology." Industrial Machinery Quarterly, 29(1), 45-62.

5. Liu, H.W., & Chen, Y.S. (2023). "Experimental Investigation of Tapered Roller Thrust Bearing Performance." Tribology International, 156, 107-122.

6. Martinez, R.A., & Brown, S.T. (2024). "Bearing Selection and Application Guide for Industrial Equipment." Machinery Lubrication Engineering, 42(4), 312-328.