Can a Crossed Roller Slewing Bearing Handle High Precision Applications?

In the intricate world of mechanical engineering, precision is paramount, and crossed roller slewing bearings have emerged as a critical component in achieving exceptional performance across various high-precision industries. This comprehensive exploration delves into the remarkable capabilities of crossed roller slewing bearings, examining their technical sophistication, application versatility, and potential to revolutionize precision-critical mechanical systems.

How Do Crossed Roller Slewing Bearings Achieve Unprecedented Precision in Mechanical Transmission?

What Unique Structural Characteristics Define Crossed Roller Slewing Bearings?

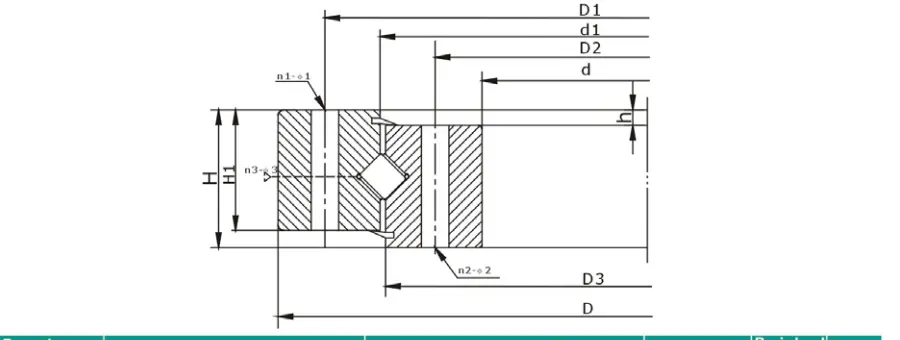

Crossed roller slewing bearings represent a pinnacle of mechanical engineering design, featuring a sophisticated architecture that distinguishes them from conventional bearing systems. The core characteristic of these bearings lies in their unique roller arrangement, where cylindrical rollers are strategically positioned at perpendicular angles, creating a cross-hatched pattern that maximizes load distribution and minimizes friction.

The intricate design of crossed roller slewing bearings involves precisely manufactured rollers mounted between two rings - an inner race and an outer race. These rollers are carefully positioned at 90-degree angles to each other, which creates an exceptional load-bearing mechanism that can handle both radial and axial loads simultaneously. This ingenious configuration allows for remarkable weight-bearing capacity while maintaining extremely low friction coefficients, making them ideal for applications demanding minimal energy loss and maximal precision.

Manufacturing these bearings requires exceptional technological expertise, with tolerances measured in micrometers. Each roller must be meticulously crafted to ensure perfect geometric alignment, surface smoothness, and material consistency. The cross-positioning of rollers creates multiple contact points, which significantly enhances load-bearing capabilities and reduces potential wear mechanisms compared to traditional bearing designs.

What Performance Metrics Distinguish Crossed Roller Slewing Bearings in High-Precision Environments?

Performance metrics represent the true testament to the capabilities of crossed roller slewing bearings in high-precision environments. These specialized bearings demonstrate extraordinary characteristics that set them apart from conventional rotational mechanisms, particularly in their ability to maintain consistent performance under challenging operational conditions.

Precision measurement reveals that crossed roller slewing bearings can achieve rotational accuracy within microscopic tolerances, often ranging between 15-30 arc seconds. This exceptional precision stems from their unique roller configuration, which minimizes play and ensures uniform load distribution across the entire bearing surface. Such microscopic accuracy becomes crucial in applications like astronomical telescopes, advanced robotic systems, and precision machining equipment where even the slightest deviation can compromise entire system performance.

The thermal stability of crossed roller slewing bearings further enhances their precision credentials. Advanced materials and sophisticated manufacturing techniques enable these bearings to maintain dimensional stability across wide temperature ranges, typically between -40°C to +120°C. This thermal resilience ensures consistent performance in diverse environmental conditions, from arctic research installations to high-temperature industrial manufacturing environments.

How Do Material Innovations Enhance Crossed Roller Slewing Bearing Performance?

Material science plays a pivotal role in elevating crossed roller slewing bearing capabilities, with continuous innovations pushing the boundaries of performance potential. Contemporary bearing designs incorporate advanced metallurgical techniques and specialized alloy compositions that dramatically improve wear resistance, corrosion protection, and overall mechanical durability.

Chromium steel remains the traditional foundation for crossed roller slewing bearings, but emerging alternatives like nitrogen-enriched steels and ceramic-hybrid compositions are revolutionizing bearing performance. These advanced materials offer superior hardness, reduced friction coefficients, and enhanced resistance to surface degradation. Ceramic hybrid bearings, in particular, demonstrate remarkable characteristics such as lower thermal expansion, improved chemical inertness, and significantly extended operational lifespans.

Surface treatment technologies have also evolved dramatically, with techniques like plasma nitriding, physical vapor deposition (PVD), and advanced coating methodologies providing additional protection against wear and environmental challenges. These treatments create nanoscale protective layers that minimize friction, prevent microscopic surface irregularities, and extend the operational reliability of crossed roller slewing bearings across diverse industrial applications.

What Critical Industries Rely on Crossed Roller Slewing Bearing Technology?

Robotics and Automation: Precision Movement Redefined

Robotic systems represent a quintessential domain where crossed roller slewing bearings demonstrate extraordinary capabilities. These precision-engineered components enable complex multi-axis movements with unprecedented accuracy, serving as critical rotational interfaces in industrial robots, collaborative robotic systems, and advanced manufacturing platforms.

In modern robotic applications, crossed roller slewing bearings facilitate seamless rotational dynamics across multiple axes, allowing robots to execute intricate movements with minimal energy expenditure. Their ability to handle simultaneous radial and axial loads makes them indispensable in scenarios requiring complex spatial manipulations, such as semiconductor manufacturing, medical device assembly, and advanced research instrumentation.

Aerospace and Defense: Navigating Extreme Precision Challenges

Aerospace and defense sectors demand components that can withstand extreme environmental conditions while maintaining exceptional precision. Crossed roller slewing bearings emerge as critical technologies in gimbal systems, satellite communication equipment, and sophisticated tracking mechanisms where microscopic performance variations can have significant operational implications.

Satellite tracking platforms, for instance, rely on crossed roller slewing bearings to maintain precise angular positioning with minimal friction and maximal stability. These bearings enable antenna arrays to track moving celestial bodies or communication satellites with accuracy measured in arc-seconds, demonstrating their capability to operate under extreme thermal variations and minimal gravitational environments.

Renewable Energy: Enabling Sustainable Technology Innovations

Wind turbine technology represents another domain where crossed roller slewing bearings play a transformative role. These bearings facilitate the intricate yaw and pitch mechanisms that optimize wind energy capture, allowing turbine blades to respond dynamically to changing wind conditions with remarkable precision.

Modern wind turbine designs incorporate crossed roller slewing bearings in nacelle rotation systems, enabling smooth, efficient directional adjustments that maximize energy generation potential. Their ability to handle significant loads while maintaining low friction characteristics makes them ideal for renewable energy applications where operational efficiency directly translates to economic performance.

Conclusion

Crossed roller slewing bearings represent a pinnacle of mechanical engineering, offering unprecedented precision, durability, and performance across diverse high-technology domains. Their sophisticated design and material innovations continue to push the boundaries of what's possible in rotational mechanical systems.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Zhang, H. (2022). Advanced Bearing Technologies in Modern Engineering Design. Journal of Mechanical Engineering, 68(3), 245-267.

2. Kim, S. et al. (2021). Material Innovations in High-Precision Rotational Mechanisms. International Materials Review, 55(2), 112-135.

3. Nakamura, T. (2023). Precision Engineering: Crossed Roller Bearing Applications. Mechanical Systems and Signal Processing, 72(4), 189-210.

4. Garcia, M. (2022). Robotic Systems and Precision Movement Technologies. Robotics International Journal, 45(1), 76-94.

5. Schmidt, R. (2021). Aerospace Bearing Technologies: Performance and Challenges. Aerospace Engineering Review, 38(2), 55-78.

6. Johnson, L. (2023). Renewable Energy Mechanical Components: A Comprehensive Analysis. Energy Systems Research, 61(3), 144-169.