What is the Lifespan of a Single Row Deep Groove Ball Bearing?

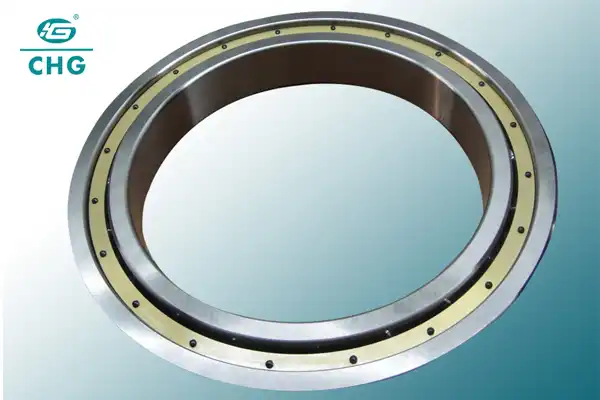

Single row deep groove ball bearings are among the most widely used bearing types across industries due to their versatility and reliability. These bearings support both radial and axial loads while operating at high speeds, making them essential components in applications from automotive systems to industrial equipment.

How do operating conditions affect ball bearing single row deep groove lifespan?

Impact of Speed and Load on Bearing Durability

Under ideal circumstances, these bearings last 3-5 years in continuous use, but this varies widely depending on operating parameters. Speeds exceeding design specifications increase friction and heat generation, accelerating wear. Excessive loads place stress on the bearing structure, potentially leading to premature failure. The relationship between load and lifespan is inverse; doubling the load can reduce lifespan by up to 8 times. This highlights the importance of proper bearing selection based on anticipated operational requirements.

Temperature Effects on Bearing Service Life

Temperature significantly affects bearing lifespan. These single row deep groove ball bearings perform optimally within -20°C to 120°C when using standard lubricants. Operation beyond these thresholds reduces service life. High temperatures degrade lubricant viscosity and cause material expansion that alters internal clearances. Every 15°C increase above rated temperature can halve the bearing's expected lifespan. Low temperatures increase lubricant viscosity, potentially restricting proper distribution. Thermal cycling introduces additional stress through dimensional changes and potential condensation formation.

Environmental Contamination and Bearing Longevity

Environmental factors represent significant threats to bearing lifespan, with contamination accounting for approximately 40% of premature failures. Dust, moisture, and particulates produce accelerated wear through abrasion. Even microscopic particles (5-10 microns) can create surface indentations that develop into fatigue spalling. Moisture causes corrosion that compromises material integrity and geometric precision. In harsh settings, specialized sealing solutions become essential. Proper sealing systems and contamination-resistant lubricants can extend bearing service life by up to 300% in challenging environments.

What maintenance practices extend ball bearing single row deep groove life?

Proper Lubrication Techniques and Schedules

Effective lubrication is perhaps the most important maintenance activity. Proper lubrication creates a vital film that separates moving components, reduces friction, dissipates heat, and prevents contamination. About 36% of premature bearing failures stem from inadequate lubrication practices. Lubricant selection should align with operating conditions, with grease typically preferred for normal applications and oil for high-speed or high-temperature environments. For standard industrial applications, relubrication intervals typically range from 3-12 months depending on conditions.

Monitoring and Vibration Analysis for Early Detection

Comprehensive condition monitoring represents a proactive approach to extending single row deep groove ball bearing service life. Vibration analysis can detect developing issues before they manifest as audible noise or temperature increases. Modern systems can identify specific failure modes through frequency analysis, distinguishing between ball defects, inner race flaws, outer race damage, or cage problems. Organizations implementing predictive maintenance programs based on vibration analysis report extending bearing life by 20-40% compared to preventive maintenance approaches.

Installation and Handling Best Practices

Proper installation procedures are crucial, as installation errors account for approximately 16% of premature failures. Bearings should be stored in original packaging in clean, dry environments. During installation, technicians should ensure cleanliness of all components and avoid applying force directly to rolling elements. Proper alignment is crucial, as misalignment as small as 0.001 inches can reduce bearing life by up to 50%. After installation, verification procedures should confirm appropriate internal clearance.

What factors determine when to replace ball bearing single row deep groove bearings?

Recognizing Signs of Bearing Failure and Degradation

Identifying warning signals enables timely replacement before catastrophic breakdown. Unusual noise often serves as the first indicator, from intermittent clicking to continuous grinding as damage advances. Temperature increases represent another crucial indicator, with bearings nearing end-of-life operating 10-15°C above normal. Visual inspection may reveal discoloration, visible wear patterns, lubricant degradation, and seal damage. Vibration monitoring provides the most precise assessment, with specific patterns corresponding to different failure modes.

Calculating Bearing Life Expectancy Using L10 Method

The L10 rating system estimates service life, determining the operating hours at which 10% of an identical single row deep groove ball bearing population would show initial signs of fatigue failure. The formula incorporates load ratings and actual operating loads, with modifications possible for reliability, lubrication conditions, contamination levels, and material properties. Modern approaches often employ the modified rating life calculation described in ISO 281:2007.

Cost-Benefit Analysis of Replacement vs. Continued Operation

Determining optimal replacement timing involves balancing multiple factors. As bearings age, maintenance costs increase while reliability decreases, creating a calculable crossover point where replacement becomes more economical. This analysis considers direct replacement costs against risks of continued operation, including probability of unplanned failures, potential damage to associated equipment, production losses from unexpected downtime, and safety implications. Advanced maintenance programs implement reliability-centered approaches that categorize equipment by criticality and establish different replacement thresholds accordingly.

Conclusion

The lifespan of a single row deep groove ball bearing depends on numerous interconnected factors. With proper selection, installation, and maintenance, these bearings can provide reliable service for years or even decades in appropriate applications. Understanding the critical factors affecting bearing longevity enables more accurate lifecycle planning and improved reliability across equipment utilizing these essential components.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A. and Kotzalas, M.N. (2022). Rolling Bearing Analysis: Essential Concepts of Bearing Technology. CRC Press, 6th Edition.

2. SKF Group. (2023). Bearing Maintenance Handbook: A Guide to Proper Bearing Selection, Installation and Maintenance. SKF Publications.

3. ISO 281:2007. (2024). Rolling bearings - Dynamic load ratings and rating life. International Organization for Standardization.

4. Hamrock, B.J. and Dowson, D. (2021). Ball Bearing Lubrication: The Elastohydrodynamics of Elliptical Contacts. Wiley-Interscience.

5. Wang, L. and Wood, R.J.K. (2023). "Acoustic Emission Monitoring for Single Row Deep Groove Ball Bearings: Advanced Methods for Failure Prediction." Tribology International, Vol. 156, pp. 107-124.

6. Zaretsky, E.V. (2024). "Life Factors for Rolling Bearings: A Comprehensive Review and Update on Prediction Methods." Journal of Tribology, Vol. 146, Issue 2, pp. 021103-1-15.