What is the Purpose of a Cross Roller Bearing?

Cross roller bearings are specialized mechanical components designed to support high loads while allowing smooth rotational movement between two parts. These bearings are crucial in various industrial applications, particularly in machinery that requires precise rotation and the ability to handle both radial and axial loads simultaneously. The unique design of cross roller bearings, featuring cylindrical rollers arranged in a perpendicular pattern, allows them to provide superior stability, accuracy, and load-bearing capacity compared to many other bearing types.

How does a cross roller slewing bearing differ from other types of bearings?

Cross roller slewing bearings stand out from other bearing types due to their distinctive design and performance characteristics. To fully appreciate these differences, it's essential to understand the unique features of cross roller slewing bearings and compare them to alternative bearing solutions.

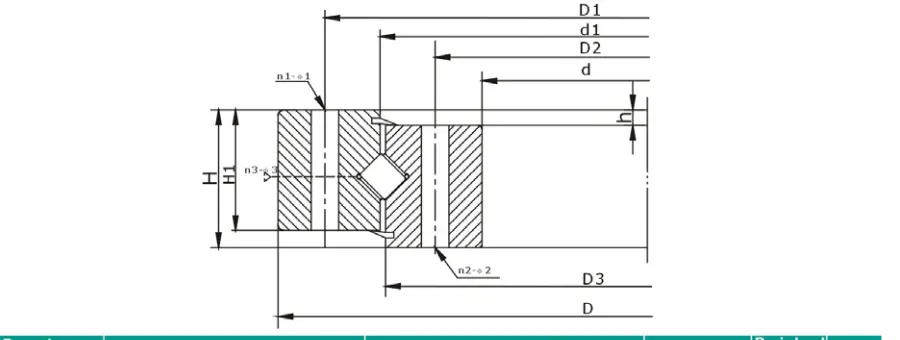

The most notable feature of cross roller slewing bearings is their roller arrangement. Unlike ball bearings or standard roller bearings, cross roller bearings have cylindrical rollers positioned at right angles to each other, forming an "X" pattern when viewed from the side. This configuration allows the bearing to handle both radial and axial loads effectively, making it ideal for applications that require multi-directional support.

One key advantage of this design is the increased contact area between the rollers and the raceways. Compared to ball bearings, which have point contact, or standard roller bearings with line contact, cross roller bearings offer a larger surface area for load distribution. This enhanced contact results in several benefits:

1. Higher load capacity: Cross roller slewing bearings can support significantly heavier loads than many other bearing types of similar size. This makes them particularly suitable for heavy machinery and equipment in industries such as construction, mining, and manufacturing.

2. Improved stability: The perpendicular arrangement of rollers provides excellent rigidity and resistance to tilting moments. This stability is crucial in applications where precise positioning and minimal deflection are required, such as in robotic arms or precision machining equipment.

3. Reduced friction: The rolling motion of the cylindrical rollers, combined with their optimized contact area, results in lower friction compared to sliding bearings or some other rotational components. This reduced friction translates to smoother operation and lower energy consumption.

4. Compact design: Cross roller slewing bearings can handle both radial and axial loads in a single unit, eliminating the need for separate bearings for different load directions. This compact design allows for space-saving solutions in complex machinery.

5. Enhanced precision: The geometry of cross roller bearings enables them to maintain high rotational accuracy even under heavy loads. This precision is vital in applications such as machine tools, medical equipment, and optical instruments.

What are the key applications of cross roller slewing bearings in industrial machinery?

Cross roller slewing bearings have found their way into a wide array of industrial applications due to their unique capabilities in handling heavy loads and providing precise rotational movement. Their versatility and reliability make them indispensable components in various sectors of industry and technology. Let's explore some of the key applications where these bearings play a crucial role:

1. Construction and Mining Equipment:

In the construction and mining industries, cross roller slewing bearings are essential components in heavy machinery such as excavators, cranes, and tunnel boring machines. These bearings are used in the slewing mechanisms that allow the upper structure of these machines to rotate smoothly and precisely, even when carrying immense loads. For example, in an excavator, the slewing bearing enables the cab and boom to rotate 360 degrees while supporting the weight of the structure and the forces generated during digging operations. The high load capacity and stability of cross roller slewing bearings ensure that these massive machines can operate efficiently and safely in challenging environments.

2. Robotics and Automation:

The robotics industry heavily relies on cross roller slewing bearings for various applications. In robotic arms and manipulators, these bearings are used in the joints to provide smooth, precise movements while supporting the weight of the arm and any payload it might be carrying. The compact design of cross roller bearings allows for the creation of sleeker, more efficient robotic systems. In automated manufacturing lines, cross roller slewing bearings are often found in rotary tables and positioning systems, where they enable precise control of workpiece orientation during machining or assembly processes. Their ability to maintain accuracy under load is crucial for ensuring the quality and consistency of manufactured products.

3. Renewable Energy Systems:

The renewable energy sector, particularly wind power, makes extensive use of cross roller slewing bearings. In wind turbines, these bearings play a critical role in the yaw system, which is responsible for keeping the turbine aligned with the wind direction. The slewing bearing allows the nacelle (the housing containing the generator and gearbox) to rotate smoothly on top of the tower, optimizing energy capture and protecting the turbine from excessive loads during high winds. The long operational life and low maintenance requirements of cross roller slewing bearings make them ideal for this application, where reliability is paramount due to the challenging access conditions of many wind turbine installations.

4. Medical Equipment:

In the medical field, cross roller slewing bearings are utilized in various diagnostic and treatment devices that require precise rotational movement. CT scanners, for instance, use these bearings to support the rotating gantry that houses the X-ray source and detectors. The high accuracy and smooth operation of cross roller bearings ensure that the scanner can produce clear, artifact-free images. Similarly, in radiation therapy equipment, these bearings enable the precise positioning of the treatment head around the patient. The stability and load capacity of cross roller slewing bearings are crucial in these applications to maintain accuracy and patient safety.

5. Aerospace and Defense:

The aerospace and defense industries employ cross roller slewing bearings in a variety of applications where reliability and precision are critical. In radar systems, these bearings are used to support and rotate antenna arrays, allowing for accurate tracking and scanning. Military vehicles, such as tanks and armored personnel carriers, use cross roller slewing bearings in their turret systems, enabling smooth and precise aiming of weapons while supporting substantial loads. In aerospace applications, these bearings can be found in satellite positioning systems and space telescopes, where their ability to operate smoothly in extreme conditions is invaluable.

How can proper maintenance extend the lifespan of cross roller slewing bearings?

Proper maintenance is crucial for maximizing the lifespan and performance of cross roller slewing bearings. These precision components are often used in critical applications where failure can lead to significant downtime, safety risks, and financial losses. By implementing a comprehensive maintenance strategy, operators can ensure that their cross roller slewing bearings continue to function optimally for extended periods. Let's explore the key aspects of proper maintenance and how they contribute to extending the lifespan of these important components.

1. Regular Inspection and Monitoring:

One of the most fundamental aspects of maintaining cross roller slewing bearings is conducting regular inspections. These inspections should be carried out at intervals determined by the application's demands and the manufacturer's recommendations. During these checks, technicians should look for signs of wear, damage, or unusual behavior. Key areas to focus on include:

- Raceway condition: Check for any signs of pitting, scoring, or uneven wear on the raceways.

- Roller condition: Inspect the rollers for any signs of damage, such as flaking or spalling.

- Seals and shields: Ensure that seals and shields are intact and effectively preventing contamination.

- Mounting and alignment: Verify that the bearing is properly mounted and aligned within the assembly.

In addition to visual inspections, implementing condition monitoring techniques can provide valuable insights into the bearing's health. Vibration analysis, for example, can detect early signs of wear or damage before they become visible. By identifying issues early, maintenance teams can plan interventions before catastrophic failure occurs, potentially saving significant time and resources.

2. Proper Lubrication:

Lubrication is perhaps the most critical factor in extending the lifespan of cross roller slewing bearings. Proper lubrication reduces friction, prevents wear, protects against corrosion, and helps dissipate heat. To ensure optimal lubrication:

- Use the correct type of lubricant: Select a lubricant that is appropriate for the bearing's operating conditions, including temperature range, load, and speed.

- Maintain proper lubricant levels: Over-lubrication can be just as harmful as under-lubrication, leading to increased friction and heat generation.

- Establish a re-lubrication schedule: Regular re-lubrication is essential to replenish the lubricant and remove contaminants.

- Consider automatic lubrication systems: For critical applications or hard-to-reach bearings, automatic lubrication systems can ensure consistent and appropriate lubrication.

It's important to note that some cross roller slewing bearings come pre-lubricated and sealed for life. In these cases, follow the manufacturer's guidelines regarding maintenance and replacement intervals.

3. Contamination Control:

Contamination is a major threat to the longevity of cross roller slewing bearings. Dust, dirt, moisture, and other particles can enter the bearing, causing abrasive wear and potentially leading to premature failure. To mitigate this risk:

- Ensure proper sealing: Verify that seals and shields are in good condition and properly installed.

- Maintain a clean environment: Keep the area around the bearing as clean as possible to minimize the risk of contamination.

- Use clean tools and handling procedures: When performing maintenance, ensure that all tools and hands are clean to avoid introducing contaminants.

- Consider implementing filtration systems: In particularly dirty environments, additional filtration measures may be necessary to protect the bearing.

4. Load Management:

While cross roller slewing bearings are designed to handle heavy loads, consistently operating at or near their maximum capacity can shorten their lifespan. To optimize bearing life:

- Avoid overloading: Ensure that the bearing is not subjected to loads beyond its rated capacity.

- Distribute loads evenly: Where possible, design systems to distribute loads evenly across the bearing.

- Consider load fluctuations: In applications with varying loads, ensure that peak loads do not exceed the bearing's capabilities.

In conclusion, cross roller slewing bearings are indispensable components in modern industrial machinery due to their ability to combine high load capacity with precision and rigidity. They are designed to handle complex loads and provide smooth rotational movement, making them suitable for a variety of applications, from construction and mining equipment to robotics and medical devices. Proper maintenance, including regular inspection, appropriate lubrication, and contamination control, is essential to extend their service life and ensure reliable performance.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. "Product Information|THK Official Web Site" provides detailed product information on cross roller bearings, including their applications and technical specifications.

2. The article "Experimental Evaluation of the Cross Roller Bearing Resistance Moment in Vacuum" discusses the resistance moment and friction coefficient of cross-roller bearings under various conditions, which is crucial for understanding their performance in different environments.

3. "Cross-Roller Ring Series - THK - PDF Catalogs | Technical Documentation" offers technical documentation and catalogs that detail the design and performance characteristics of cross-roller rings, a specific type of cross roller bearing.

4. "Stiffness Characteristics of Crossed Roller Bearings With Roller Roundness Deformation" is a research paper that investigates the stiffness characteristics of these bearings, which is an important factor in their application in precision machinery.

5. "Modeling of Crossed Roller Bearings Considering Roller Roundness Deformation" presents a model for predicting the performance of crossed roller bearings, taking into account deformation, which can affect their load capacity and stiffness.

6. "ROLLING BEARINGS HANDBOOK - NTN Americas" is a comprehensive handbook that includes information on the selection, installation, and maintenance of various types of rolling bearings, including cross roller bearings.