What Industries Use Taper Roller Thrust Bearings?

Taper roller thrust bearings are a critical component in various industries due to their ability to handle both radial and axial loads. These bearings are designed to support heavy loads and are often used in applications where high precision and durability are essential. This blog will explore the industries that commonly use taper roller thrust bearings, highlighting their unique applications and benefits.

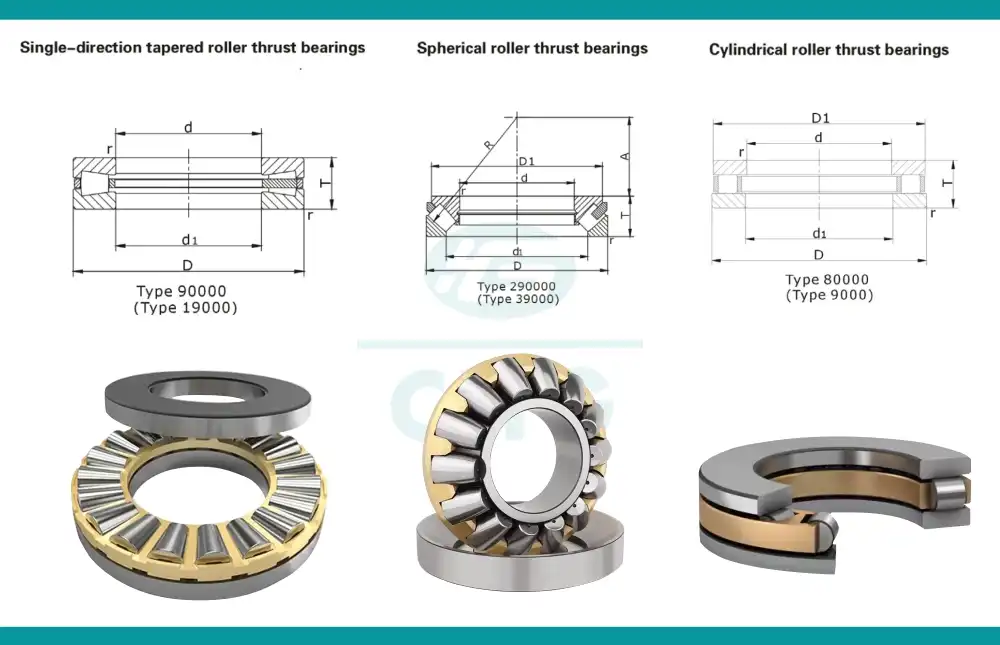

What Are the Different Types of Taper Roller Thrust Bearings?

Single-Row Taper Roller Thrust Bearings

Single-row taper roller thrust bearings are designed to handle both radial and axial loads. These bearings are typically used in applications where space is limited, and high load capacity is required. The single-row design allows for easy installation and maintenance, making them a popular choice in various industries. Taper roller thrust bearings of this type are often found in automotive and industrial machinery, where they provide reliable and efficient performance.

Double-Row Taper Roller Thrust Bearings

Double-row taper roller thrust bearings are designed to handle even heavier loads than their single-row counterparts. These bearings feature two rows of tapered rollers, which provide increased load capacity and stability. They are commonly used in heavy machinery, construction equipment, and industrial applications where high load capacity and reliability are critical. The double-row design ensures that the bearing can withstand extreme conditions and prolonged use, making it a valuable component in these industries.

Four-Point Contact Taper Roller Thrust Bearings

Four-point contact taper roller thrust bearings are designed to handle axial loads in both directions. These bearings feature a unique design that allows them to distribute loads evenly, providing enhanced stability and durability. They are commonly used in applications where reversing axial loads are present, such as in gearboxes, pumps, and compressors. The four-point contact design ensures that the bearing can withstand high loads and provide reliable performance in demanding conditions.

How Do Taper Roller Thrust Bearings Work?

Load Distribution

Taper roller thrust bearings work by distributing loads evenly across their tapered rollers. The rollers are arranged in a way that allows them to handle both radial and axial loads efficiently. This design ensures that the bearing can withstand high loads and provide stable performance in various applications. The tapered design of the rollers allows for smooth and efficient load distribution, reducing wear and tear and extending the lifespan of the bearing.

Lubrication

Proper lubrication is essential for the efficient operation of taper roller thrust bearings. Lubrication reduces friction between the rollers and the bearing surfaces, ensuring smooth and efficient operation. Various types of lubricants, including grease and oil, can be used depending on the application and working conditions. Proper lubrication helps to extend the lifespan of the bearing and ensures reliable performance in demanding conditions.

Installation and Maintenance

The installation and maintenance of taper roller thrust bearings are crucial for their long-term performance. Proper installation ensures that the bearing is aligned correctly and can handle loads efficiently. Regular maintenance, including inspection and lubrication, helps to extend the lifespan of the bearing and ensures reliable performance. Proper installation and maintenance practices help to prevent premature failure and ensure that the bearing provides optimal performance in various applications.

What Are the Benefits of Using Taper Roller Thrust Bearings?

High Load Capacity

One of the primary benefits of using taper roller thrust bearings is their high load capacity. These bearings are designed to handle both radial and axial loads efficiently, making them suitable for various applications. The tapered design of the rollers allows for even load distribution, ensuring stable and reliable performance. The high load capacity of these bearings makes them a popular choice in industries where heavy loads and demanding conditions are common.

Durability and Reliability

Taper roller thrust bearings are known for their durability and reliability. The tapered design of the rollers and the robust construction of the bearing ensure that it can withstand high loads and demanding conditions. Proper lubrication and maintenance further enhance the durability and reliability of these bearings, making them a valuable component in various industries. The ability to handle high loads and provide stable performance makes taper roller thrust bearings a reliable choice for demanding applications.

Versatility

Taper roller thrust bearings offer versatility in their applications. They can be used in various industries, including automotive, construction, and industrial machinery. The ability to handle both radial and axial loads makes them suitable for a wide range of applications, from gearboxes to pumps and compressors. The versatility of these bearings ensures that they can meet the specific needs of different industries and applications, making them a valuable component in various settings.

Conclusion

Taper roller thrust bearings play a crucial role in various industries due to their high load capacity, durability, and versatility. Understanding the different types, working principles, and benefits of these bearings can help industries make informed decisions when selecting the right bearing for their applications. Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Bearing Engineering Handbook, 4th Edition, by McGraw-Hill Professional.

2. Rolling Bearing Analysis, by John Wiley & Sons.

3. Bearing Design and Application, by CRC Press.

4. Tapered Roller Bearings: Design, Application, and Maintenance, by Industrial Press.

5. Bearing Failure: Causes and Cures, by ASM International.

6. Mechanical Bearings: Selection, Design, and Application, by Marcel Dekker, Inc.