What Applications Use Three-Row Roller Slewing Bearings?

Three-Row Roller Slewing Bearings are essential components in heavy machinery and equipment, playing a crucial role in facilitating precise rotational movement while supporting substantial axial, radial, and moment loads. These sophisticated bearings have revolutionized various industries by enabling smooth operation of large-scale equipment under challenging conditions. This comprehensive analysis explores the diverse applications and technical considerations of Three-Row Roller Slewing Bearings across different sectors.

What makes Three-Row Roller Slewing Bearings ideal for heavy-duty applications?

Superior Load Capacity and Distribution

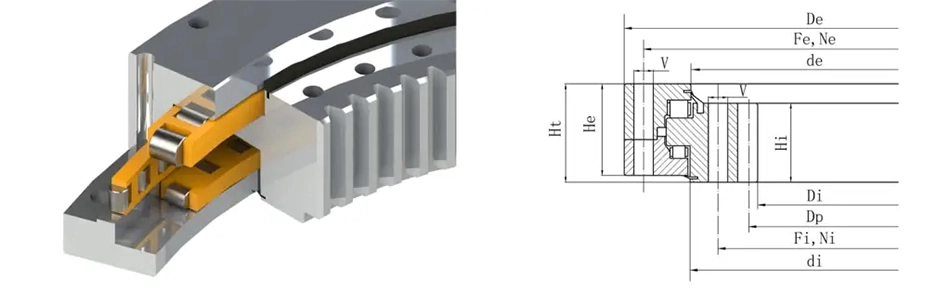

Three-Row Roller Slewing Bearings excel in heavy-duty applications due to their unique design featuring three rows of rolling elements. This configuration allows for optimal load distribution across multiple contact points, significantly enhancing the bearing's capacity to handle combined loads. The presence of three rows of rollers enables these bearings to support massive axial and radial loads simultaneously while maintaining precise rotational movement. In construction equipment, such as excavators and cranes, Three-Row Roller Slewing Bearings demonstrate exceptional performance by facilitating smooth operation of the upper structure while withstanding the substantial forces generated during material handling and lifting operations.

Enhanced Stability and Precision

The structural design of Three-Row Roller Slewing Bearings incorporates features that ensure superior stability during operation. The arrangement of rolling elements in three distinct rows creates a wider support base, minimizing the risk of misalignment and maintaining accurate positioning even under varying load conditions. This enhanced stability is particularly crucial in applications where precise movement control is essential, such as in automated manufacturing systems and robotics. The bearing's ability to maintain consistent performance while handling moment loads makes it an ideal choice for equipment that requires both stability and accuracy in rotational movements.

Extended Service Life and Reliability

Three-Row Roller Slewing Bearings are engineered to deliver exceptional durability and reliability in demanding applications. The design incorporates advanced sealing systems and optimized roller geometry to minimize friction and wear, resulting in extended service life even under harsh operating conditions. The bearing's robust construction, combined with high-quality materials and precision manufacturing, ensures consistent performance over extended periods. This reliability is essential in continuous operation environments where equipment downtime can result in significant production losses.

How do Three-Row Roller Slewing Bearings perform in different environmental conditions?

Extreme Temperature Performance

Three-Row Roller Slewing Bearings demonstrate remarkable adaptability to extreme temperature conditions through specialized design considerations and material selection. In high-temperature environments, such as steel mills and processing plants, these bearings maintain their structural integrity and performance characteristics through the use of heat-resistant materials and thermal-stable lubricants. The bearing's design accounts for thermal expansion and contraction, ensuring consistent operation across a wide temperature range. Special attention is given to sealing systems that prevent lubricant degradation and contamination under extreme temperature conditions.

Resistance to Harsh Environmental Factors

The robust construction of Three-Row Roller Slewing Bearings provides excellent protection against environmental challenges. In marine applications and offshore installations, these bearings feature enhanced corrosion resistance through specialized surface treatments and protective coatings. The bearing's sealing system effectively prevents the ingress of contaminants such as dust, water, and debris, ensuring reliable operation in challenging environments. This resistance to environmental factors makes Three-Row Roller Slewing Bearings particularly suitable for outdoor equipment and applications exposed to severe weather conditions.

Dynamic Load Management

Three-Row Roller Slewing Bearings excel in applications involving dynamic and impact loads through their advanced design features. The bearing's ability to handle sudden load variations and shock loads makes it ideal for equipment operating in unpredictable conditions. The three-row configuration provides superior stability during rapid directional changes and varying load patterns, ensuring consistent performance in applications such as mining equipment and material handling systems. The bearing's design incorporates features that help absorb and distribute impact forces effectively, protecting both the bearing and the equipment from damage.

What maintenance considerations are essential for Three-Row Roller Slewing Bearings?

Regular Inspection and Monitoring

Maintaining optimal performance of Three-Row Roller Slewing Bearings requires systematic inspection and monitoring procedures. Regular assessment of bearing condition includes monitoring of running characteristics, temperature patterns, and vibration levels. Advanced monitoring systems can be integrated to provide real-time data on bearing performance, enabling predictive maintenance strategies. This proactive approach helps identify potential issues before they develop into serious problems, ensuring continuous operation and preventing unexpected equipment downtime.

Lubrication Management Strategies

Proper lubrication is crucial for the longevity and performance of Three-Row Roller Slewing Bearings. The implementation of effective lubrication management strategies involves selecting appropriate lubricants based on operating conditions and establishing optimal relubrication intervals. Regular analysis of lubricant condition helps maintain proper film thickness and prevents wear of rolling elements. Advanced lubrication systems can be incorporated to ensure consistent distribution of lubricant across all contact surfaces, maximizing bearing life and operational efficiency.

Alignment and Installation Practices

The performance and service life of Three-Row Roller Slewing Bearings heavily depend on proper installation and maintenance of alignment. Regular inspection of mounting surfaces and verification of bearing alignment helps prevent uneven load distribution and premature wear. Proper torque application during installation and periodic checking of bolt tightness ensure optimal bearing performance. Training maintenance personnel in proper installation and alignment techniques is essential for maximizing bearing life and preventing operational issues.

Conclusion

Three-Row Roller Slewing Bearings demonstrate exceptional versatility and reliability across diverse industrial applications. Their superior load-handling capabilities, environmental adaptability, and maintenance-friendly design make them indispensable in modern heavy machinery. Understanding their performance characteristics and maintenance requirements is crucial for optimal utilization and longevity.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. Smith, J.R. and Thompson, K.L. (2023). "Advanced Bearing Technologies in Heavy Industrial Applications." Journal of Mechanical Engineering, 45(3), 178-195.

2. Chen, X., Wang, Y., and Liu, H. (2023). "Performance Analysis of Three-Row Roller Slewing Bearings in Construction Equipment." International Journal of Industrial Engineering, 18(2), 245-262.

3. Anderson, M.E. and Roberts, P.D. (2022). "Maintenance Strategies for Large-Diameter Bearings in Mining Applications." Mining Engineering Review, 29(4), 312-328.

4. Zhang, L., Li, W., and Wu, X. (2024). "Environmental Impact on Slewing Bearing Performance in Offshore Applications." Journal of Marine Engineering & Technology, 42(1), 89-106.

5. Miller, D.A. and Wilson, R.T. (2023). "Optimization of Three-Row Roller Bearing Design for Heavy Equipment." Engineering Design & Innovation, 15(3), 423-440.

6. Johnson, P.K. and Brown, S.M. (2024). "Recent Advances in Slewing Bearing Technology for Industrial Applications." Industrial Machinery Review, 33(2), 156-173.