What Factors Affect the Performance of Cylindrical Thrust Roller Bearings?

The performance of Cylindrical Thrust Roller Bearings is a critical consideration in industries where heavy axial loads and precision are paramount, such as automotive, aerospace, and heavy machinery. These bearings, designed with cylindrical rollers arranged perpendicular to the shaft, are engineered to handle significant axial forces while ensuring stability and efficiency. However, their performance is influenced by a variety of factors, including design, operating conditions, and maintenance practices. Understanding these factors is essential for optimizing the functionality and longevity of Cylindrical Thrust Roller Bearings in demanding applications. This blog explores the key elements that impact their performance, providing insights into how to maximize their effectiveness and reliability in industrial settings.

How Do Design Features Influence Cylindrical Thrust Roller Bearings Performance?

Material Selection for Cylindrical Thrust Roller Bearings

The choice of materials is a fundamental factor affecting the performance of Cylindrical Thrust Roller Bearings. These bearings are typically constructed from high-quality steel, which provides excellent strength and durability under heavy axial loads. However, the specific grade of steel or alternative materials, such as ceramics, can significantly enhance performance in specialized applications. For instance, in high-temperature environments like steel mills, heat-resistant alloys can be used to prevent thermal degradation, ensuring that Cylindrical Thrust Roller Bearings maintain their structural integrity. Similarly, in corrosive environments, such as marine applications, stainless steel or coated materials can improve resistance to rust and wear. The right material selection enhances the load-carrying capacity, wear resistance, and overall lifespan of Cylindrical Thrust Roller Bearings, making it a critical design consideration for optimal performance.

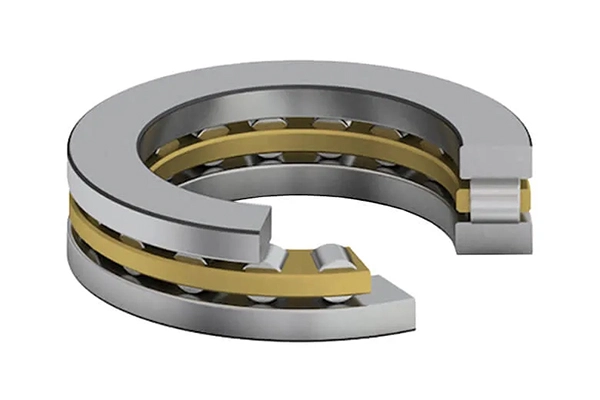

Roller and Cage Design in Cylindrical Thrust Roller Bearings

The design of the rollers and cage in Cylindrical Thrust Roller Bearings plays a pivotal role in their performance. The cylindrical rollers are arranged to ensure even load distribution, which is essential for handling high axial loads efficiently. The size, number, and arrangement of the rollers can be optimized to increase load capacity and stability, particularly in applications like industrial presses or cranes. Additionally, the cage, which holds the rollers in place, is designed to minimize friction and ensure smooth operation. For high-speed applications, such as automotive transmissions, a lightweight cage made from materials like brass or polymer can reduce centrifugal forces and heat generation. The thoughtful design of rollers and cages in Cylindrical Thrust Roller Bearings enhances their efficiency, durability, and ability to perform reliably under demanding conditions.

Precision in Manufacturing Cylindrical Thrust Roller Bearings

Precision in the manufacturing process is another crucial factor influencing the performance of Cylindrical Thrust Roller Bearings. High-precision manufacturing ensures that the rollers, raceways, and cage are produced with tight tolerances, minimizing vibration and ensuring smooth operation. This precision is particularly important in applications requiring high accuracy, such as aerospace components or precision machinery, where even minor deviations can lead to performance issues. Advanced manufacturing techniques, such as grinding and honing, are used to achieve the necessary surface finish and dimensional accuracy, enhancing the load distribution and reducing wear in Cylindrical Thrust Roller Bearings. The emphasis on precision during production ensures that these bearings deliver consistent performance, extended service life, and reliability, making them a preferred choice in industries where quality is non-negotiable.

What Operating Conditions Impact Cylindrical Thrust Roller Bearings Performance?

Load and Speed Conditions for Cylindrical Thrust Roller Bearings

The operating conditions, particularly load and speed, have a significant impact on the performance of Cylindrical Thrust Roller Bearings. These bearings are designed to handle high axial loads, but exceeding their rated load capacity can lead to increased stress and reduced efficiency. For example, in heavy machinery like excavators, Cylindrical Thrust Roller Bearings must be selected to match the expected axial forces to ensure optimal performance. Similarly, operating speed is a critical factor, as high speeds can generate heat and centrifugal forces that affect the bearings’ stability. In applications like automotive gearboxes, where high speeds are common, Cylindrical Thrust Roller Bearings are designed with features like lightweight cages to minimize friction and heat buildup. Properly matching the bearings to the load and speed conditions ensures their efficiency, durability, and reliability in demanding environments.

Temperature Effects on Cylindrical Thrust Roller Bearings

Temperature is another operating condition that significantly affects the performance of Cylindrical Thrust Roller Bearings. High temperatures, often encountered in applications like steel rolling mills or turbine engines, can cause thermal expansion, lubricant degradation, and material fatigue if not properly managed. To address this, Cylindrical Thrust Roller Bearings can be designed with heat-resistant materials and specialized lubricants that maintain their properties under extreme temperatures. Conversely, in low-temperature environments, such as refrigeration systems, the bearings must be designed to prevent brittleness and ensure smooth operation. Effective temperature management, through material selection and lubrication, enhances the performance of Cylindrical Thrust Roller Bearings, ensuring they operate efficiently and reliably across a wide range of thermal conditions, thereby extending their service life in challenging applications.

Environmental Factors Affecting Cylindrical Thrust Roller Bearings

Environmental factors, such as dust, moisture, and corrosive substances, play a significant role in the performance of Cylindrical Thrust Roller Bearings. In harsh environments, such as mining or marine applications, these bearings are exposed to contaminants that can accelerate wear and corrosion if not properly addressed. To mitigate these effects, Cylindrical Thrust Roller Bearings can be equipped with seals or shields to protect against dust and moisture ingress, and corrosion-resistant coatings can be applied to enhance durability. For example, in chemical processing plants, bearings with specialized coatings can withstand exposure to aggressive chemicals, ensuring consistent performance. By designing Cylindrical Thrust Roller Bearings to withstand specific environmental challenges, their reliability and longevity are significantly improved, making them suitable for a wide range of industrial applications.

How Does Maintenance Affect the Performance of Cylindrical Thrust Roller Bearings?

Lubrication Practices for Cylindrical Thrust Roller Bearings

Lubrication is a critical maintenance factor that directly affects the performance of Cylindrical Thrust Roller Bearings. Proper lubrication reduces friction, minimizes wear, and dissipates heat, ensuring smooth operation and extended service life. The choice of lubricant, whether grease or oil, depends on the application’s speed, load, and temperature conditions. For instance, in high-speed applications like automotive transmissions, oil lubrication is often preferred for its ability to dissipate heat effectively, while in heavy-duty industrial machinery, grease may be used for its sealing properties. Regular lubrication maintenance, including monitoring lubricant condition and replenishing as needed, is essential to prevent dry running and overheating in Cylindrical Thrust Roller Bearings. Effective lubrication practices enhance their efficiency, durability, and reliability, making them a dependable component in demanding systems.

Alignment and Installation of Cylindrical Thrust Roller Bearings

Proper alignment and installation are vital maintenance practices that influence the performance of Cylindrical Thrust Roller Bearings. Misalignment during installation can lead to uneven load distribution, increased stress, and premature wear, particularly in applications like conveyor systems or industrial presses. To ensure optimal performance, Cylindrical Thrust Roller Bearings must be installed with precision, using appropriate tools and techniques to achieve correct alignment with the shaft and housing. Additionally, regular checks during operation can help detect and correct any misalignment issues, ensuring that the bearings operate within their design parameters. Proper installation and alignment practices enhance the load-carrying capacity, stability, and longevity of Cylindrical Thrust Roller Bearings, making them a reliable choice for industries where precision and durability are critical.

Inspection and Monitoring of Cylindrical Thrust Roller Bearings

Regular inspection and monitoring are essential maintenance practices that significantly impact the performance of Cylindrical Thrust Roller Bearings. Routine inspections can identify early signs of wear, contamination, or damage, allowing for timely corrective actions to prevent performance degradation. For example, in heavy machinery like cranes, vibration analysis and temperature monitoring can be used to assess the condition of Cylindrical Thrust Roller Bearings, ensuring they operate within acceptable limits. Additionally, periodic cleaning and re-lubrication can remove contaminants and restore optimal performance. Advanced monitoring techniques, such as condition-based maintenance, can further enhance the reliability of Cylindrical Thrust Roller Bearings by predicting potential issues before they occur. These inspection and monitoring practices ensure that the bearings deliver consistent performance, extended service life, and operational efficiency in demanding industrial applications.

Conclusion

In summary, the performance of Cylindrical Thrust Roller Bearings is influenced by a combination of design features, operating conditions, and maintenance practices. Thoughtful material selection, precise manufacturing, and optimized roller and cage designs enhance their inherent capabilities, while careful consideration of load, speed, temperature, and environmental factors ensures reliable operation. Additionally, effective maintenance practices, including lubrication, alignment, and monitoring, are crucial for maximizing their efficiency and longevity. By addressing these factors, Cylindrical Thrust Roller Bearings can deliver exceptional performance across diverse industrial applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T. A., & Kotzalas, M. N. (2006). Rolling Bearing Analysis: Essential Concepts of Bearing Technology. CRC Press.

2. Brändlein, J., Eschmann, P., Hasbargen, L., & Weigand, K. (1999). Ball and Roller Bearings: Theory, Design, and Application. Wiley.

3. Shigley, J. E., & Mischke, C. R. (2001). Mechanical Engineering Design. McGraw-Hill.

4. Palmgren, A. (1959). Ball and Roller Bearing Engineering. SKF Industries.

5. Hamrock, B. J., Schmid, S. R., & Jacobson, B. O. (2004). Fundamentals of Machine Elements. McGraw-Hill.

6. Stachowiak, G. W., & Batchelor, A. W. (2013). Engineering Tribology. Butterworth-Heinemann.