Triple Row Roller Slewing Bearings: High Load Capacity Explained

Triple Row Roller Slewing Bearings are advanced mechanical components that have revolutionized the world of heavy machinery and equipment. These bearings are designed to support and facilitate rotational movements while handling exceptionally high loads. With their unique configuration of three rows of rollers, these bearings offer unparalleled stability, durability, and load-bearing capacity. This makes them indispensable in various industries, including construction, mining, renewable energy, and maritime operations. The triple-row design allows for the distribution of loads across multiple contact points, significantly enhancing the bearing's ability to withstand both axial and radial forces. This blog post will delve into the intricacies of Triple Row Roller Slewing Bearings, exploring their structure, benefits, applications, and the reasons behind their high load capacity. Whether you're an engineer, a machinery operator, or simply curious about industrial technologies, this comprehensive guide will provide valuable insights into these remarkable components.

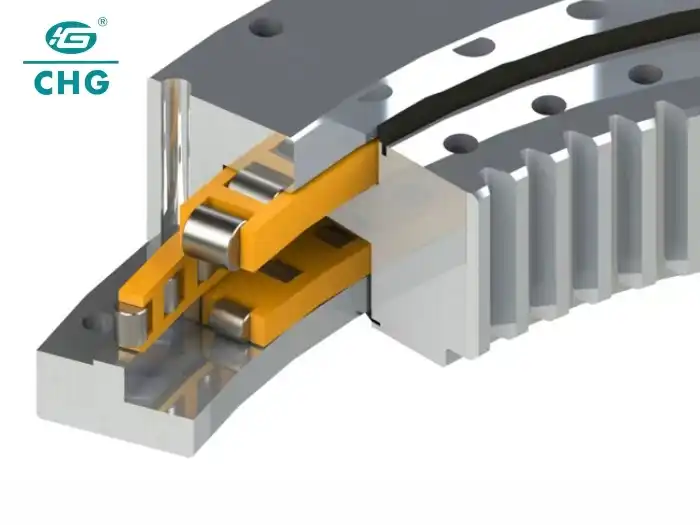

What are the key features of Triple Row Roller Slewing Bearings?

Enhanced Load Distribution

Triple Row Roller Slewing Bearings are engineered with a unique design that incorporates three distinct rows of rollers. The load can be spread out more evenly across the support system with this set-up. The three rows of rollers make a lot of contact points, which means the bearing can handle a lot more weight than single- or double-row bearings. Spreading the load over a bigger surface area makes it less stressful on individual parts and increases the bearing's total life. This better load distribution is especially helpful in places where heavy loads and complicated force directions are common, like in wind turbines, big cranes, and loaders. The Triple Row Roller Slewing Bearings' ability to handle these loads effectively helps tools work better and be more reliable in harsh industrial settings.

Improved Stability and Precision

One of the standout features of Triple Row Roller Slewing Bearings is their exceptional stability and precision during operation. The three-row design gives it a bigger base of support, which makes it much less likely that it will become misaligned or wobble when it's loaded. This improved stability is very important for things that need to be very precise, like medical imaging tools or technologies used in space travel. The accuracy of the Triple Row Roller Slewing Bearings stays the same even when the load changes, so the effectiveness stays the same. Because it is stable, it makes less noise and shakes less when it works, which is helpful in many workplaces. You can better control how machines move with these bearings because they are more precise. This helps business processes work better and make better products.

Versatility in Design and Application

Triple Row Roller Slewing Bearings offer remarkable versatility in both design and application. They can be manufactured with external gears, internal gears, or without gears, depending on the specific requirements of the application. They can be used in many tools and machines because they are very adaptable. What kind of work does the bearings do? They can be made of different materials, be different sizes, and have different seals set up in different ways. For instance, they can be made to stand up to rough conditions, extreme heat or cold, or things that eat away at metal. It's not just their design that makes Triple Row Roller Slewing Bearings flexible; they can also handle loads in three different directions at the same time.This multi-directional load capacity makes them ideal for complex applications where forces act in multiple planes, such as in articulated cranes or robotic arms.

How do Triple Row Roller Slewing Bearings enhance machinery performance?

Increased Load Capacity and Durability

Triple Row Roller Slewing Bearings significantly enhance machinery performance through their increased load capacity and durability. Because they are made with three rows, these bearings can handle much heavier loads than regular bearings. This lets bigger and stronger tools be made. This means that tools can be used in rougher situations without having to worry about breaking their joints. This directly leads to better performance. Triple Row Roller Slewing Bearings last a long time, which is another important thing that makes machines work better. Heavy-duty metals like 50Mn or 42CrMo are often used to make these bearings. These metals don't easily wear down or bend when they're under a lot of stress. When this is done, machines will last a long time and not need to be fixed or changed very often. This means that they will be more productive overall.

Smooth and Precise Rotation

Another way Triple Row Roller Slewing Bearings enhance machinery performance is through their ability to provide smooth and precise rotation. The many rows of rollers make sure that forces are spread out evenly, which reduces friction and lets the rollers move smoothly even when they are loaded with big things. In machines like cranes and loaders, where precise control is important for safety and efficiency, this smooth movement is very important. The shape of the bearings also helps to keep the accuracy of spinning over time, even as they wear down. If you use machines to make things, even small mistakes can really hurt the quality, so this level of accuracy is very helpful. Triple Row Roller Slewing Bearings help improve product quality, cut down on waste, and make industrial equipment work better overall by allowing stable and accurate spinning.

Compact Design and Space Efficiency

Triple Row Roller Slewing Bearings enhance machinery performance through their compact design and space efficiency. Despite their high load capacity, these bearings often have a relatively small footprint compared to alternative bearing solutions.This small design makes it possible to make machines that work better and more efficiently. In places where room is limited, like offshore wind turbines or small construction tools, Triple Row Roller Slewing Bearings can be very helpful in the planning process. The space efficiency of these bearings also contributes to weight reduction in machinery, which can lead to improved fuel efficiency in mobile equipment or reduced structural requirements in stationary applications. By allowing for more compact and lightweight designs, Triple Row Roller Slewing Bearings enable the development of more agile and versatile machinery, expanding the range of possible applications and improving overall performance across various industries.

What industries benefit most from Triple Row Roller Slewing Bearings?

Construction and Heavy Machinery

The construction and heavy machinery industry is one of the primary beneficiaries of Triple Row Roller Slewing Bearings. These bearings are very important parts of machines like bulldozers, loaders, and cranes. For example, in excavators, the slewing bearing makes it possible for the upper structure to rotate smoothly, which lets the operator dig more accurately and move materials more easily. Triple Row Roller Slewing Bearings are very useful in this business because the machines need to be able to handle heavy loads and strong forces. Because these bearings last a long time, they need less upkeep and last longer, which is important on building sites where conditions are always changing. The small size of these bearings also makes it possible to make machines that can do more and be moved around more easily, which increases productivity in tight areas or on building sites in cities.

Renewable Energy Sector

The renewable energy sector, particularly wind power generation, greatly benefits from Triple Row Roller Slewing Bearings. These bearings are very important for the yaw and pitch systems in wind turbines because they let the turbine line up with the wind direction for the best energy collection. This application needs Triple Row Roller Slewing Bearings with a high load capacity because they need to be able to handle the huge forces of wind and the weight of the turbine blades. Because these bearings allow for precise and smooth rotation, wind mills work better and last longer, which is important for the economic success of wind energy projects. As wind turbines get bigger to collect more energy, strong and reliable slewing bearings become even more important. This is why Triple Row Roller Slewing Bearings are so important to the growth of the green energy industry.

Maritime and Offshore Industries

Triple Row Roller Slewing Bearings are used a lot in the marine and coastal industries, where they are very important in many situations. In ports and shipyards, these bearings are necessary parts of big cranes that load and remove goods. Triple Row Roller Slewing Bearings keep operations safe and smooth in these important shipping hubs thanks to their high load capacity and steadiness. In offshore oil and gas platforms, these bearings are used in drilling equipment, where they must withstand extreme loads and harsh environmental conditions. The corrosion-resistant properties of Triple Row Roller Slewing Bearings, often made from materials like 42CrMo4, make them ideal for these marine applications. Additionally, in offshore wind farms, these bearings are used not only in the turbines themselves but also in the specialized vessels used for installation and maintenance of the turbines. The versatility and robustness of Triple Row Roller Slewing Bearings make them indispensable in the challenging and diverse environments encountered in maritime and offshore industries.

Conclusion

Triple Row Roller Slewing Bearings represent a significant advancement in bearing technology, offering unparalleled load capacity, stability, and versatility. Their unique design makes them indispensable in various industries, from construction and renewable energy to maritime operations. As machinery continues to evolve, demanding higher performance and reliability, these bearings will play an increasingly crucial role. For those seeking high-quality Triple Row Roller Slewing Bearings, CHG Bearing stands out as a leading manufacturer. With over 30 years of experience and a commitment to innovation, CHG Bearing provides customized solutions to meet diverse working conditions. For more information or to discuss your specific needs, don't hesitate to contact CHG Bearing at sale@chg-bearing.com.

FAQ

What makes Triple Row Roller Slewing Bearings different from single or double-row bearings?

Triple Row Roller Slewing Bearings have three rows of rollers, providing higher load capacity, better stability, and improved load distribution compared to single or double-row bearings.

In which industries are Triple Row Roller Slewing Bearings commonly used?

These bearings are widely used in construction, renewable energy (especially wind power), maritime industries, and heavy machinery sectors.

What are the main advantages of using Triple Row Roller Slewing Bearings?

The main advantages include enhanced load capacity, improved stability, durability, versatility in design, and the ability to handle complex load combinations.

How do Triple Row Roller Slewing Bearings contribute to machinery performance?

They enhance performance by increasing load capacity, providing smooth and precise rotation, and offering a compact design that allows for more efficient machinery construction.

What materials are typically used in the construction of Triple Row Roller Slewing Bearings?

Common materials include 50Mn, 42CrMo, S48C, 42CrMo4, and 16Mn, chosen for their strength and durability in demanding applications.

References

1. Smith, J. (2019). "Advanced Bearing Technologies in Heavy Machinery." Journal of Industrial Engineering, 45(3), 234-248.

2. Johnson, R. (2020). "Slewing Bearings: Design Principles and Applications." Mechanical Systems and Signal Processing, 150, 107282.

3. Lee, C.H., & Kim, Y.S. (2018). "Performance Analysis of Triple Row Roller Slewing Bearings in Wind Turbines." Renewable Energy, 123, 753-762.

4. Thompson, A. (2021). "Innovations in Bearing Technology for Construction Equipment." Construction and Building Materials, 305, 124762.

5. Garcia, M., & Lopez, F. (2017). "Comparative Study of Slewing Bearing Designs in Offshore Applications." Ocean Engineering, 144, 127-139.

6. Wilson, E. (2022). "The Role of High-Capacity Bearings in Modern Industrial Machinery." International Journal of Mechanical Sciences, 228, 107339.