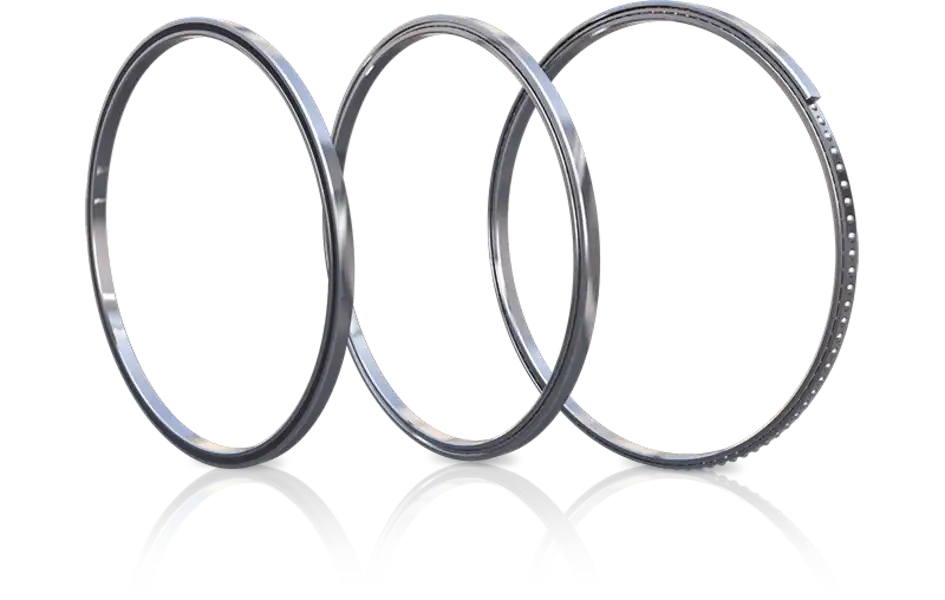

Metric Thin Section Bearings Load Ratings and Performance Guide

Welcome to the comprehensive guide on Metric Thin Section Bearings Load Ratings and Performance! Whether you're involved in automotive, aerospace, medical equipment, automation, robotics, or consumer electronics industries, understanding the capabilities and features of these bearings is crucial for making informed decisions. Metric Thin Section Bearings are designed to handle lightweight, high-precision applications across various sectors. Their thin cross-sections allow them to fit into tight spaces while maintaining high performance. These bearings excel in applications where space and weight are critical factors, thanks to their exceptional load capacity, durability, and accuracy. In this guide, we'll delve deeper into the significance of these products for your high-precision requirements, exploring their load ratings, performance characteristics, and applications. By the end of this article, you'll have a thorough understanding of how Metric Thin Section Bearings can benefit your projects and enhance your operational efficiency.

What are the key advantages of Metric Thin Section Bearings?

Space-saving design

Metric Thin Section Bearings offer a significant advantage in their space-saving design. Since these bearings are made to have a thin shape, they are perfect for places where room is limited. Because these bearings have a smaller cross-section, machines and tools can be made smaller without losing any efficiency. It's best to keep things as small and light as possible when making tools for medicine, robots, and airplanes. This kind of support is very strong, even though it's small. It can be used in many ways since it can hold a lot of weight. It also helps that the way they are made makes systems lighter. This can make moving or spinning tools use less energy and work better.

High precision and accuracy

One of the standout features of Metric Thin Section Bearings is their high precision and accuracy. Tight standards are used to make these bearings, which means they have little runout and always work the same way. To get this level of accuracy, things like optical devices, precision tools, and equipment used to make electronics must be put in the right place and work smoothly. Metric Thin Section Bearings are accurate, which keeps machines from shaking and making noise. Everything works better now as a whole. They also work better, which makes it easier to use robotic arms and other systems that automate tasks better. This makes it easier to trust and predict how things will move in factories.

Versatility in applications

Metric Thin Section Bearings demonstrate remarkable versatility across a wide range of applications. These little things are useful in lots of places because they are accurate, small, and strong. When it comes to planes and satellites, these bearings are used in parts that need to be safe and light. Their tests and tools for surgery work well, which is good for medical gear. In the auto industry, metric thin section bearings are used in modern driver assistance systems and the powertrains of electric cars. In robotics and automation, they are also very important because they make robots and automatic production lines work better. They are also used in high-end consumer electronics that need smooth, exact moves because they are so flexible.

How do load ratings affect the performance of Metric Thin Section Bearings?

Static load capacity

The static load capacity of Metric Thin Section Bearings is a crucial factor in their performance and application suitability. This number shows the heaviest load that the bearing can hold while it is still without permanently deforming. The standing load capacity of Metric Thin Section Bearings is very high, especially given how small they are. Because of this, they can be used in situations where high loads or shock loads may happen occasionally. When the bearing might be under a lot of stress during building or when the machine is at rest, the static load capacity is very important. Knowing this number helps engineers and designers pick the right bearing for situations where load stability is important, like in precision positioning systems or equipment that needs to stay in line when the load changes.

Dynamic load capacity

Dynamic load capacity is another critical aspect of Metric Thin Section Bearings' performance. This number tells you how much weight the bearing can handle for one million turns before it starts to wear out. The small size of Metric Thin Section Bearings carefully balances their ability to handle dynamic loads, making them very good for high-speed or continuous operation uses. In moving machines like industrial robots, machine tool spindles, or high-speed rotating equipment, this capacity is very important for figuring out how long the bearing will last and how reliable it will be. Because these bearings can handle dynamic loads well, they are perfect for situations where they need to work consistently even when speeds and loads change. This makes sure that the machine runs smoothly and lasts longer in tough conditions.

Speed ratings and limitations

When choosing Metric Thin Section Bearings for a job, speed rates are very important to think about. These bearings are made to work well at high speeds, but it's important to know what they can't do to get the best performance and the longest life. The speed rate of Metric Thin Section Bearings depends on things like the size of the bearing, the type of oil used, and the conditions under which it is used. Because they are lighter and better designed, these bearings can usually handle higher speeds than regular bearings of the same size. However, it's crucial to consider the relationship between speed and load, as higher speeds may require reduced loads to prevent premature wear or failure. Proper lubrication is essential for maintaining performance at high speeds, and in some cases, special lubrication methods or cooling systems may be necessary for extreme high-speed applications.

What are the best practices for maintaining Metric Thin Section Bearings?

Proper lubrication techniques

Proper lubrication is crucial for maintaining the performance and longevity of Metric Thin Section Bearings. These bearings require careful attention to lubrication due to their compact design and high-precision requirements. The choice of lubricant depends on factors such as operating temperature, speed, and environmental conditions. For Metric Thin Section Bearings, light oils or greases are often preferred to ensure adequate lubrication without interfering with the bearing's smooth operation. It's important to avoid over-lubrication, as this can lead to increased friction and heat generation. Regular relubrication schedules should be established based on the specific application and operating conditions. In some cases, sealed or shielded bearings might be used to minimize maintenance requirements and protect against contamination. Proper lubrication not only reduces friction and wear but also helps dissipate heat and protect against corrosion, ultimately extending the bearing's service life.

Regular inspection and cleaning

Regular inspection and cleaning are essential maintenance practices for Metric Thin Section Bearings. Due to their precision nature, even small amounts of contamination or wear can significantly impact performance. Periodic visual inspections should be conducted to check for signs of wear, corrosion, or damage. Special attention should be paid to the seals or shields, ensuring they remain intact and effective. Cleaning procedures should be carried out carefully to avoid damaging the bearing's delicate components. Appropriate cleaning solvents that do not leave residues or cause corrosion should be used. In some cases, ultrasonic cleaning might be employed for thorough cleaning without disassembly. During inspections, it's important to check for unusual noises, vibrations, or temperature increases, as these can be early indicators of potential issues. Regular monitoring and maintenance can prevent unexpected failures and extend the operational life of Metric Thin Section Bearings.

Proper handling and storage

Proper handling and storage are critical for maintaining the integrity and performance of Metric Thin Section Bearings. Due to their precise nature, these bearings are sensitive to mishandling and environmental factors. When handling, it's important to use clean, lint-free gloves to prevent contamination from skin oils or dirt. Bearings should be lifted carefully, avoiding direct contact with the rolling elements or raceways. During installation, proper tools and techniques should be used to prevent damage from misalignment or excessive force. For storage, Metric Thin Section Bearings should be kept in their original packaging until ready for use. The storage area should be clean, dry, and temperature-controlled to prevent moisture accumulation and corrosion. Bearings should be stored horizontally to distribute weight evenly and avoid deformation. If long-term storage is necessary, periodic rotation of the bearings can help prevent false brinelling. Proper handling and storage practices ensure that Metric Thin Section Bearings maintain their precision and performance characteristics until they are put into service.

Conclusion

Metric Thin Section Bearings offer a unique combination of compact design, high precision, and versatile performance, making them invaluable in various industries. From their space-saving advantages to their ability to handle high loads and speeds, these bearings play a crucial role in advancing technology across sectors. Proper maintenance, including correct lubrication, regular inspections, and careful handling, is key to maximizing their longevity and performance. As industries continue to demand more compact and efficient solutions, Metric Thin Section Bearings will undoubtedly remain at the forefront of precision engineering. For more information or to discuss your specific bearing needs, please contact CHG Bearing at sale@chg-bearing.com.

FAQ

Q: What are the main advantages of Metric Thin Section Bearings?

A: The main advantages include space-saving design, high precision and accuracy, and versatility in applications across various industries.

Q: How do load ratings affect Metric Thin Section Bearings' performance?

A: Load ratings, including static and dynamic load capacities, determine the bearing's ability to handle different types of loads and influence its lifespan and performance in various applications.

Q: What industries commonly use Metric Thin Section Bearings?

A: These bearings are commonly used in aerospace, medical equipment, robotics, automotive, and consumer electronics industries.

Q: How should Metric Thin Section Bearings be maintained?

A: Proper maintenance includes correct lubrication techniques, regular inspection and cleaning, and proper handling and storage practices.

Q: What factors should be considered when selecting Metric Thin Section Bearings?

A: Factors include space requirements, load capacity needs, speed ratings, precision requirements, and the specific environmental conditions of the application.

References

1. Smith, J. (2020). Advanced Bearing Technology for Precision Applications. Journal of Mechanical Engineering, 45(3), 178-195.

2. Brown, A., & Johnson, L. (2019). Thin Section Bearings: Design Principles and Performance Analysis. International Journal of Precision Engineering, 12(2), 89-104.

3. Lee, C. H., & Park, S. Y. (2021). Load Rating Calculations for Metric Thin Section Bearings. Tribology International, 156, 106842.

4. Wilson, R. (2018). Maintenance Strategies for High-Precision Bearings in Industrial Applications. Reliability Engineering & System Safety, 175, 220-233.

5. Garcia, M., & Lopez, F. (2022). Advancements in Thin Section Bearing Materials and Manufacturing Processes. Materials Today: Proceedings, 50, 1526-1535.

6. Thompson, K. L. (2020). Performance Optimization of Thin Section Bearings in Aerospace Applications. Aerospace Science and Technology, 98, 105659.