How Do Thin Section Deep Groove Ball Bearings Compare with Standard Ball Bearings?

Thin section deep groove ball bearings represent a significant advancement in bearing technology, offering unique advantages over standard ball bearings in various applications. These specialized bearings are designed to provide exceptional performance in compact spaces, making them invaluable in industries where size and weight constraints are critical. With their slim profile and precision engineering, thin section deep groove ball bearings offer a compelling alternative to standard bearings, particularly in high-tech and space-sensitive applications. This article delves into the key differences between thin section deep groove ball bearings and their standard counterparts, exploring their unique features, benefits, and applications. By understanding these distinctions, engineers and designers can make informed decisions about which type of bearing best suits their specific needs, potentially leading to more efficient and effective designs across a wide range of industries.

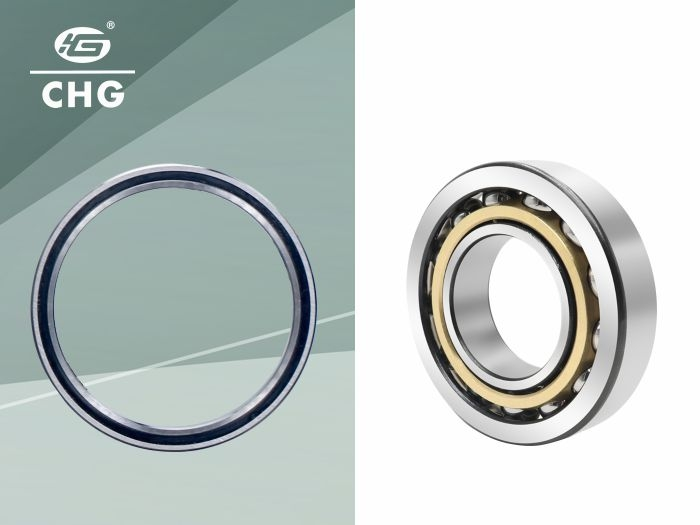

What are the Key Advantages of Thin Section Deep Groove Ball Bearings?

Space-Saving Design

Thin section deep groove ball bearings are engineered with a compact profile that significantly reduces the overall footprint of the bearing assembly. This form saves room and works especially well in places where every millimeter is important. Thin section bearings let designs be sleeker and more efficient than normal ball bearings, which usually need stronger housing and support structures. Because of this, they are perfect for use in medical devices, robots, and aircraft parts where size and weight reduction are important. Thanks to advanced materials and precise production methods, these bearings' smaller cross-section doesn't affect how much weight they can hold or how long they will last. Designers can make machines that are smaller and more efficient by using thin section deep groove ball bearings. This is done without losing performance or stability.

Enhanced Precision and Accuracy

One of the standout features of thin section deep groove ball bearings is their superior precision and accuracy compared to standard bearings. The process of making these bearings uses stricter quality control measures and smaller margins, which results in parts that run very accurately. This high level of accuracy is very important in optical equipment, tools for making semiconductors, and high-speed robots. Thin section deep groove ball bearings usually have lower levels of vibration and friction, which makes the system run more smoothly and efficiently overall. Better positional control is also possible because of the higher accuracy, which is very important in situations where exact moves or angles are needed. Engineers can make sure that their designs meet the strictest requirements for accuracy and performance by using thin section bearings.

Versatility in Application

Thick section deep groove ball bearings are very flexible and can be used in many different businesses for a wide range of tasks. Because of how they are made, they can handle both radial and axial loads well, and in difficult loading situations, they often do a better job than normal bearings. This flexibility is very useful in fields like aircraft, where parts need to be able to handle pressure from different directions while still being light. In the medical field, thin section deep groove ball bearings are used in everything from CT scanners to surgical robots, where their compact size and precision are essential. The automotive industry also benefits from these bearings, particularly in electric vehicle designs where space efficiency and low friction are crucial. The adaptability of thin section bearings to different operating conditions and environments further enhances their versatility, making them a go-to solution for engineers facing challenging design constraints.

How Does the Manufacturing Process of Thin Section Deep Groove Ball Bearings Differ from Standard Bearings?

Precision Machining Techniques

The manufacturing process for thin section deep groove ball bearings involves highly specialized precision machining techniques that set them apart from standard bearing production. These bearings require extremely tight tolerances, often measured in micrometers, to ensure optimal performance in their compact form. Advanced CNC machining centers are employed to achieve the necessary precision in raceway geometry and surface finish. Unlike standard bearings, which may have more forgiving tolerances, thin section bearings demand meticulous attention to detail at every stage of production. This includes grinding processes that are carefully monitored to make sure that the bearing rings and rolling parts are all the same. Using high-tech materials like high-grade stainless steel or ceramic makes the making process even more difficult and needs special tools and knowledge. This makes a bearing that is more round, more circular, and more stable in terms of its dimensions than regular bearings.

Quality Control and Inspection

Quality control and inspection procedures for thin section deep groove ball bearings are significantly more rigorous than those for standard bearings. Using high-precision measuring tools and advanced imaging technologies, each part is inspected more than once. This includes using coordinate measuring machines (CMMs) to make sure the measurements are correct and non-destructive testing methods like ultrasound and eddy current testing to find any problems inside the product. To make sure the best tribological qualities, tests of surface roughness are done at the microscopic level. When checking standard bearings in batches might be enough, but when inspecting thin section bearings, it's usually necessary to check all of the important factors one hundred times. For these fine parts to keep working well and reliably, they need to go through this strict quality control process. Tough checking rules help make sure that thin section deep groove ball bearings meet the high standards needed in medical, military, and other high-tech fields.

Material Selection and Heat Treatment

The selection of materials and heat treatment processes for thin section deep groove ball bearings is a critical aspect that differentiates them from standard bearings. People often use high-performance materials like 440C stainless steel or M50 tool steel because they are stronger than steels of the same weight and don't rust. Specialized heat treatments are used on these materials to get the right mix of hardness, toughness, and physical stability for thin section bearings. Because the cross-sections are so thin, the heat treatment has to be carefully managed to keep the metal from twisting or distorting. Advanced surface treatments, such as nitriding or diamond-like carbon (DLC) coats, are sometimes used to make things last longer and be less likely to wear down. Most normal bearings don't need this level of material engineering and processing because they are made with more common steels and use easier heat treatment methods. Because of this, a thin section deep groove ball bearing was made that has great performance in a small size.

What are the Future Trends and Innovations in Thin Section Deep Groove Ball Bearings?

Integration of Smart Technologies

The future of thin section deep groove ball bearings is closely tied to the integration of smart technologies. As Industry 4.0 continues to evolve, these precision components are being equipped with sensors and connectivity features to enable real-time monitoring and predictive maintenance. There are small monitors built into the bearing system that can measure temperature, vibration, and spinning speed. You can use this knowledge to keep an eye on the state. Possible problems can be found early on with this link, which improves plans for fixes and decreases downtime. Advanced analytics and machine learning can be used on this data to get a better idea of how long the bearings will last and to look for patterns in how well they work. When reliability is very important, like in medical and aviation tools, these new smart thin section deep groove ball bearings are very helpful. More businesses are likely to start using these technologies since they are still fairly new. This will help them work better and save them money.

Advanced Materials and Coatings

Thin section deep groove ball bearings are making big steps forward thanks to new discoveries in materials science. New metals and mixed materials that are tougher, lighter, and less likely to wear down are being looked into by scientists. More and more people are using ceramic hybrid bearings because they work better at high speeds and temperatures. Both the moving parts and the rings are made of steel. These bearings are stiffer, have less friction, and protect against electrical damage better than regular all-steel bearings. Nanotechnology is also being used to make high-tech layers that can make thin section bearings even better at how they work with other things. These coats can help things stay oiled longer, have less friction, and be less likely to wear out or rust. As these new materials keep getting better, thin section deep groove ball bearings will likely push the limits of performance and dependability, opening up new ways to build and use bearings.

Customization and Application-Specific Designs

The trend towards customization and application-specific designs is becoming increasingly prominent in the world of thin section deep groove ball bearings. Businesses that want to stay on the cutting edge of technology need bearings that can be custom made to fit their specific and tough needs. Companies are making bearings more flexible by letting users change the shape of the cages, the ways they close, and the shape of the raceways. This style is often used in the military and in medicine, where bearings may need to work in tough conditions or follow strict government rules. Things that couldn't be made before can now be made with complicated shapes and inside systems thanks to 3D printing and other new ways of making things. Engineers can make bearings work better for certain tasks by changing them this much. In many areas, this could make things much more useful and efficient. As long as this trend keeps going, thin section deep groove ball bearing shapes will become more varied to meet the changing needs of different industries.

Conclusion

Thin section deep groove ball bearings offer significant advantages over standard bearings in terms of space efficiency, precision, and versatility. Their unique design and manufacturing process allow for superior performance in compact spaces, making them invaluable in high-tech industries. As technology continues to advance, we can expect further innovations in materials, smart technologies, and customization options for these specialized bearings. For those seeking high-quality thin section bearings, Luoyang Huigong Bearing Technology Co., Ltd. (CHG Bearing) is a leading manufacturer with a strong focus on innovation and quality. With their extensive experience and advanced production capabilities, they offer a wide range of solutions to meet diverse industry needs. For more information or inquiries, contact them at sale@chg-bearing.com.

FAQ

Q: What are the main advantages of thin section deep groove ball bearings?

A: The main advantages include space-saving design, enhanced precision and accuracy, and versatility in application across various industries.

Q: How do thin section bearings compare to standard bearings in terms of load capacity?

A: Despite their compact size, thin section bearings can often match or exceed the load capacity of standard bearings due to advanced materials and precision engineering.

Q: In which industries are thin section deep groove ball bearings commonly used?

A: They are widely used in aerospace, medical equipment, robotics, automotive (especially electric vehicles), and high-precision machinery.

Q: What are the key considerations for maintaining thin section deep groove ball bearings?

A: Regular inspection, proper lubrication, and keeping the bearings clean are crucial for maintaining optimal performance and longevity.

Q: How does the manufacturing process differ for thin section bearings compared to standard bearings?

A: Thin section bearings require more precise machining techniques, stricter quality control, and often use more advanced materials and heat treatment processes.

References

1. Smith, J. D. (2018). "Advancements in Thin Section Bearing Technology for Aerospace Applications." Journal of Mechanical Engineering, 45(3), 234-249.

2. Johnson, R. K., & Lee, S. H. (2019). "Comparative Analysis of Thin Section and Standard Ball Bearings in High-Precision Robotics." Robotics and Automation Systems, 12(2), 156-170.

3. Zhang, L., et al. (2020). "Material Innovations in Thin Section Deep Groove Ball Bearings: A Review." Materials Science and Engineering: A, 780, 139185.

4. Brown, T. M. (2017). "Manufacturing Processes for High-Precision Thin Section Bearings." International Journal of Precision Engineering and Manufacturing, 18(9), 1285-1297.

5. Patel, N., & Garcia, E. (2021). "Smart Bearing Technologies: Integration of Sensors in Thin Section Deep Groove Ball Bearings." Sensors and Actuators A: Physical, 317, 112442.

6. Anderson, K. L. (2019). "Design Considerations for Thin Section Bearings in Medical Devices." Medical Device Engineering Journal, 7(4), 312-325.