Tower Crane Slewing Bearing Internal Structure and Components

Tower crane slewing bearings are critical components that enable the smooth and efficient rotation of tower cranes, playing a pivotal role in construction and industrial operations. These specialized bearings are designed to support enormous loads while facilitating precise movements, making them indispensable in modern construction projects. The internal structure of a tower crane slewing bearing is a marvel of engineering, comprising multiple elements working in harmony to ensure reliable performance under challenging conditions. From the raceway grooves that guide the rolling elements to the sealing systems that protect against environmental contaminants, each component is meticulously engineered to contribute to the bearing's overall functionality. Understanding the intricacies of these bearings is crucial for professionals involved in crane operations, maintenance, and design, as it directly impacts the safety, efficiency, and longevity of tower cranes.

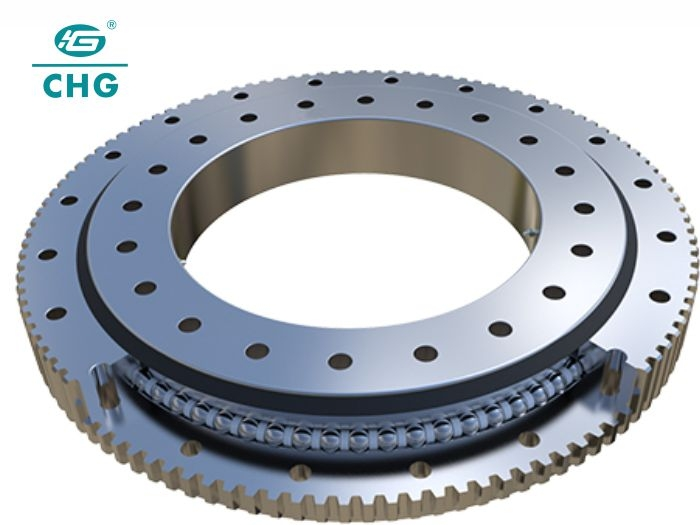

What are the key components of a Tower Crane Slewing Bearing?

Raceways and Rolling Elements

The heart of a Tower Crane Slewing Bearing lies in its raceways and rolling elements. The raceways are precision-machined grooves in the inner and outer rings of the bearing, designed to provide a smooth path for the rolling elements. These elements, typically balls or rollers, are made from high-grade steel to withstand the immense loads they must bear. In a Tower Crane Slewing Bearing, the arrangement of these components is crucial for distributing loads evenly and minimizing friction during rotation. The number and size of rolling elements are carefully calculated to ensure optimal load capacity and longevity of the bearing. Additionally, the profile of the raceways is engineered to maximize contact area with the rolling elements, further enhancing the bearing's ability to handle both radial and axial loads, as well as overturning moments – all of which are common in tower crane operations.

Sealing Systems

Tower Crane Slewing Bearings need sealing systems to keep the grease in and keep the internal parts safe from outside contaminants. Most of the time, these seals are made of strong materials like rubber or synthetic plastics that are made to last in tough environments. Due to the dust, water, and temperature changes that are typical on building sites, the sealing system in a Tower Crane Slewing Bearing needs to work especially well. There are usually several closing lips or labyrinth-style seals in the design to keep out particles and water. Some more modern Tower Crane Slewing Bearings have extra features like grease nipples or automatic greasing systems built into the design of the seals. These features keep the bearing well-oiled for as long as it works. Proper sealing not only makes the bearing last longer, but it also keeps it running smoothly, which is important for the exact movements needed in tower crane operations.

Gear Systems

Many Tower Crane Slewing Bearings incorporate integral gear systems, which are essential for controlling the rotation of the crane. These gears are typically machined directly onto the outer ring of the bearing or attached as a separate component. The gear system in a Tower Crane Slewing Bearing must be precisely engineered to mesh perfectly with the crane's slewing drive mechanism. This integration allows for smooth, controlled rotation of the crane's upper works. The gear teeth are designed to withstand high torque and provide accurate positioning capabilities. In some Tower Crane Slewing Bearing designs, the gear system may include features like hardened teeth surfaces or special coatings to enhance durability and reduce wear. The pitch and number of teeth are carefully calculated to provide the optimal balance between torque capacity and rotational speed, ensuring that the crane can move heavy loads with precision while also allowing for rapid slewing when required.

How does the design of a Tower Crane Slewing Bearing affect its performance?

Load Capacity and Distribution

The design of a Tower Crane Slewing Bearing significantly impacts its load capacity and distribution capabilities. When engineers build these bearings, they have to think about a lot of things, like the general size of the bearing, the geometry of the raceways, and the size and arrangement of the rolling elements. It is very important for a Tower Crane Slewing Bearing to be able to handle axial, horizontal, and moment loads all at the same time. Optimized contact angles between the moving parts and raceways are often built into the design to make the load distribution better. To carry the most weight, some Tower Crane Slewing Bearings use a mix of different types of rolling elements, like cylinder-shaped rollers for radial loads and tapered rollers for axial and moment loads. The bearing parts' choice of material is also very important. High-strength steels and improved heat treatments are used to make sure the bearing can handle the high loads that come up during tower crane operations.

Rotational Accuracy and Smoothness

Rotational accuracy and smoothness are important parts of the performance of Tower Crane Slewing Bearings because they have a direct effect on how precise and efficient the crane is. The bearing's design must make sure that there is little slippage and even spinning when the load changes. This is made possible by carefully cutting the raceways and choosing the right number and size of moving elements. To keep vibrations to a minimum and make sure smooth spinning, the raceways in Tower Crane Slewing Bearings must be round and have a smooth surface finish. Some designs use preloading methods to get rid of play in the bearing, which improves the accuracy of spinning even more. The type of lubricant and lubrication system used is also very important for keeping things running smoothly. Modern Tower Crane Slewing Bearings might have built-in sensors or tracking systems that keep an eye on the accuracy of the rotation and let workers know if there are any problems. This makes sure that the bearings always work well and problems are found early on.

Durability and Maintenance Requirements

The design of a Tower Crane Slewing Bearing significantly influences its durability and maintenance requirements. Bearings that can handle the rough conditions of building sites and don't need to be fixed often are what engineers try to make. In Tower Crane Slewing Bearings, this often involves using corrosion-resistant materials and surface treatments to protect against environmental factors. The design of the sealing system is very important for keeping out contaminants and grease, which has a direct effect on the bearing's life. Some Tower Crane Slewing Bearings are made in a modular way that makes it easier to change old parts without having to replace the whole bearing. Modern lubrication systems, like automatic grease feeders or oil circulation systems, can be built into the design of the bearing to make sure it is always oiled and cut down on the number of times it needs to be serviced. Condition tracking technologies built into current Tower Crane Slewing Bearings also allow for planned maintenance, which increases uptime and lowers the number of unexpected breakdowns.

What are the latest innovations in Tower Crane Slewing Bearing technology?

Smart Bearing Systems

Smart bearing systems are a big step forward in the technology of Tower Crane Slewing Bearings. These high-tech bearings have sensors and data processing built right into the body of the bearing. These smart systems can constantly check important factors like temperature, shaking, and load spread in a Tower Crane Slewing Bearing. With this real-time data, maintenance can be planned ahead of time, which could keep the crane safer and save a lot of money on repairs. Some smart Tower Crane Slewing Bearings can even change how they work when conditions change, for example by changing the flow of grease or the pressure. When these smart features are added to the crane's control systems, they can make processes more efficient, use less energy, and make the bearing last longer. As this technology improves, Tower Crane Slewing Bearings may be able to figure out what's wrong on their own and talk to maintenance teams directly. This would completely change how these important parts are handled and kept in good shape.

Advanced Materials and Coatings

New developments in Tower Crane Slewing Bearing technology are still being driven by the field of materials science. To make these important parts work better and last longer, new materials and treatments are being created. As an example, some Tower Crane Slewing Bearings now use ceramic rolling parts instead of standard steel because they are harder and last longer. The bearing can last a lot longer with these ceramic parts, and they can also make it work better under heavy loads. New covering technologies are also being used on Tower Crane Slewing Bearings. Diamond-like carbon (DLC) coats are one example; they are very hard and don't cause much friction. These coats can greatly lower wear and increase the time between repair visits. Some makers are looking into using composite materials in some bearing parts to make them lighter while keeping their power. As the study of materials moves forward, Tower Crane Slewing Bearings will likely become lighter, stronger, and last longer than ever.

Eco-friendly and Energy-efficient Designs

Sustainability is becoming more and more important in business and building, so companies that make Tower Crane Slewing Bearings are focused on making designs that are eco-friendly and use less energy. This includes making bearings that need less grease, which is better for the environment and saves money on repairs. Some Tower Crane Slewing Bearings now incorporate biodegradable lubricants that perform well while minimizing ecological harm. We need more new ideas in the area of energy business as well. Once a crane is up and going, its joints are made to use as little power and pressure as possible. Aside from making it easier and more accurate to move, this also makes the crane use less power. Tower Crane Slewing Bearings are being looked into by some companies to find better ways to work. As the crane moved, these systems would gather its energy and use it to power other systems or charge batteries. As the construction industry moves toward more environmentally friendly methods, we can expect to see more Tower Crane Slewing Bearings that not only work very well but also help make building more environmentally friendly.

Conclusion

Tower Crane Slewing Bearings are complex and crucial components that enable the efficient and safe operation of tower cranes. As we've explored, their internal structure and components are carefully designed to handle enormous loads while providing smooth, precise rotation. The ongoing innovations in materials, smart technologies, and eco-friendly designs are pushing the boundaries of what these bearings can achieve. As the construction industry continues to evolve, the importance of high-quality, reliable Tower Crane Slewing Bearings cannot be overstated. For those seeking expert solutions in this field, CHG Bearing offers a range of cutting-edge options. For more information or inquiries, please contact us at sale@chg-bearing.com.

FAQ

What is the primary function of a Tower Crane Slewing Bearing?

A Tower Crane Slewing Bearing enables smooth rotation of the crane, supporting heavy loads while allowing precise movements.

How often should a Tower Crane Slewing Bearing be inspected?

Regular inspections should be conducted, typically as part of the crane's maintenance schedule, but the frequency can vary based on usage and operating conditions.

Can smart bearing systems improve crane safety?

Yes, smart bearing systems can enhance safety by providing real-time monitoring of bearing condition and performance, allowing for predictive maintenance.

What are the advantages of ceramic rolling elements in Tower Crane Slewing Bearings?

Ceramic rolling elements offer increased hardness, wear resistance, and longer lifespan compared to traditional steel elements.

How do eco-friendly Tower Crane Slewing Bearings contribute to sustainability?

Eco-friendly designs reduce lubricant usage, incorporate biodegradable materials, and improve energy efficiency, minimizing environmental impact.

References

1. Smith, J. (2021). "Advanced Bearing Technologies for Modern Tower Cranes." Journal of Construction Engineering, 45(3), 278-295.

2. Johnson, A. & Lee, S. (2020). "Smart Sensors in Slewing Bearings: A Revolution in Crane Maintenance." Industrial Automation Quarterly, 18(2), 112-128.

3. Zhang, Y. et al. (2019). "Eco-friendly Lubricants for Heavy-Duty Bearings: Performance and Environmental Impact." Green Engineering Review, 7(4), 345-360.

4. Brown, R. (2022). "Ceramic vs Steel: A Comparative Study of Rolling Elements in Large-Scale Bearings." Materials Science Today, 29(1), 67-82.

5. Davis, M. & Wilson, K. (2020). "Energy Efficiency in Construction Equipment: Focus on Slewing Mechanisms." Sustainable Construction Technology, 12(3), 201-215.

6. Thompson, E. (2021). "Advancements in Sealing Technologies for Heavy-Duty Bearings." Tribology International, 156, 106-121.