How to Select the Right Double Row Cylindrical Roller Bearing?

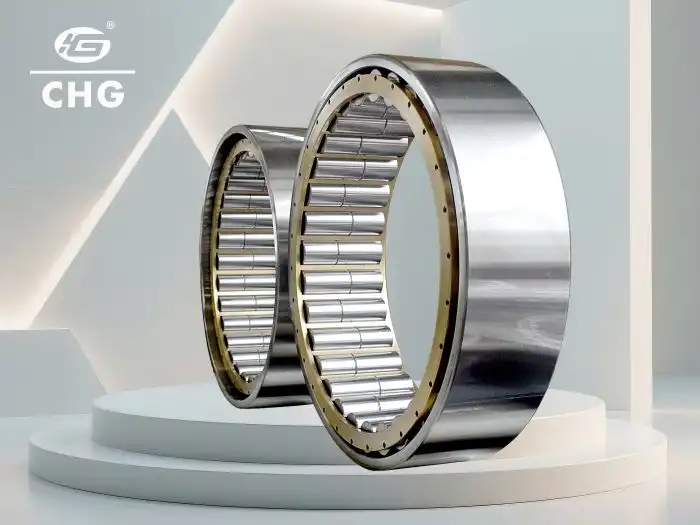

Selecting the right Double Row Cylindrical Roller Bearing is crucial for ensuring optimal performance and longevity in various industrial applications. These bearings are designed to handle high radial loads and provide superior stability, making them indispensable in heavy-duty machinery. With their unique construction featuring two parallel rows of cylindrical rollers, these bearings offer exceptional load-carrying capacity and rigidity. When choosing the appropriate Double Row Cylindrical Roller Bearing, it's essential to consider factors such as load requirements, operating conditions, speed, and environmental factors. This comprehensive guide will walk you through the key considerations and provide valuable insights to help you make an informed decision. By understanding the intricacies of these bearings and their applications, you'll be better equipped to select the ideal Double Row Cylindrical Roller Bearing for your specific needs, ultimately enhancing the efficiency and reliability of your equipment.

What are the Key Factors to Consider When Choosing a Double Row Cylindrical Roller Bearing?

Load Capacity and Type

When selecting a Double Row Cylindrical Roller Bearing, one of the primary factors to consider is its load capacity and the type of load it will be subjected to. For uses that need to handle big loads, these bearings are perfect because they are made to handle high radial loads. Because there are more wheels and contact places in a double-row cylindrical roller bearing, it can usually hold more weight than a single-row bearing. It's important to think about the size and direction of the loads in your application to make sure the bearing you choose can handle them. Also, think about whether the loads are steady or moving, as this will affect how well the bearing works and how long it lasts. Double Row Cylindrical Roller Bearings are particularly well-suited for applications with predominantly radial loads, but they can also accommodate limited axial loads in certain designs.

Operating Speed and Temperature

The operating speed and temperature are critical factors in selecting the right Double Row Cylindrical Roller Bearing. The speed needs of your tools are very important to think about when using these bearings in high-speed situations. It is important to carefully check the bearing's speed rate to make sure it meets the needs of your application. Temperature also has a big effect on how well bearings work and how long they last. Double Row Cylindrical Roller Bearings work well in a wide range of temperatures, but they may need extra care in very cold or very hot conditions. When temperatures are high, they can change the lubricant qualities and the stability of the material, and when temperatures are low, they can change the bearing's limits for size. To keep things running smoothly and keep them from breaking too soon, it's important to choose a bearing that can handle the temperature changes that are likely to happen in your working area.

Dimensional and Tolerance Requirements

Proper fitment is essential for the optimal performance of Double Row Cylindrical Roller Bearings. It's important to think about the size and accuracy needs of your product when choosing these bearings. The bearing's inner and outer diameters, as well as its width, must be precisely matched to the shaft and housing dimensions. Tight tolerances are often necessary to ensure proper alignment and prevent issues such as misalignment or excessive play. Double Row Cylindrical Roller Bearings are available in various series, including NNU and NN, each with specific dimensional characteristics. The NNU series features an outer ring with two ribs and an inner ring without ribs, while the NN series has an inner ring with two ribs and an outer ring without ribs. Consider the available space and mounting requirements when choosing between these designs. Additionally, some Double Row Cylindrical Roller Bearings are available with tapered bores (suffix K), allowing for radial clearance adjustment during installation.

How Do Environmental Factors Influence the Selection of Double Row Cylindrical Roller Bearings?

Contamination and Sealing

When choosing Double Row Cylindrical Roller Bearings and considering how well they work, the environment is very important. One big worry is smog, which can shorten the life of bearings and make them work less well. It is important to choose bearings that can seal well when working in places with dust, dirt, or water. A roller that has two rows of cylinders. Different types of seals, like contact seals, non-contact seals, and labyrinth seals, can be used on bearings based on how safe they need to be. Dirt and other things can't get into the bearing and mess up the working parts because of these plugs. If the bearing will be near chemicals or other things that break down metal, it is very important to pick one that is made of materials or covers that don't rust. The bearing will last a long time and work well if you do this.

Lubrication Requirements

Proper lubrication is vital for the optimal performance and longevity of Double Row Cylindrical Roller Bearings. What kind of climate the bearing works in can have a big effect on the oil and method used to grease it. Standard grease or oil lubrication may be enough in clean, controlled settings. But in dirty or harsh settings, it might be necessary to use special oils with better qualities. When choosing the right oil, you should think about things like the working temperature, speed, and load. In some situations, oil greasing may be needed to help heat escape and remove contaminants. The lubrication method, whether it's grease guns, automatic lubricators, or circulating oil systems, should also be considered based on the bearing's location and accessibility.

Vibration and Shock Loads

Environmental factors such as vibration and shock loads can significantly impact the performance and lifespan of Double Row Cylindrical Roller Bearings. In applications where these conditions are present, it's crucial to select bearings that can withstand these dynamic forces. Double Row Cylindrical Roller Bearings are inherently well-suited for handling vibration due to their high stiffness and load capacity. However, in extreme cases, additional measures may be necessary. Consider bearings with enhanced internal clearances or special cage designs that can better accommodate vibration and shock loads. In some instances, external damping systems or isolation mounts may be required to protect the bearings from excessive vibration. It's essential to analyze the frequency and magnitude of vibrations in your application to ensure the selected bearing can maintain its performance and reliability under these challenging conditions.

What are the Best Practices for Installing and Maintaining Double Row Cylindrical Roller Bearings?

Proper Installation Techniques

Correct installation is crucial for the optimal performance and longevity of Double Row Cylindrical Roller Bearings. Before installation, ensure that all components, including the bearing, shaft, and housing, are clean and free from contaminants. Use appropriate tools and techniques to mount the bearing, avoiding excessive force that could damage the rolling elements or raceways. For bearings with a tapered bore (suffix K), pay special attention to achieving the correct radial clearance during mounting. It's essential to follow the manufacturer's guidelines for heating (if required) and press-fitting to prevent damage to the bearing. Proper alignment is critical; use precision instruments to ensure the bearing is correctly positioned relative to the shaft and housing. Double Row Cylindrical Roller Bearings are often used in pairs, so it's important to consider the axial clearance and preload requirements when installing multiple bearings.

Regular Maintenance and Inspection

Implementing a regular maintenance and inspection routine is essential for maximizing the service life of Double Row Cylindrical Roller Bearings. Periodic checks should include monitoring vibration levels, temperature, and noise to detect any early signs of wear or potential failure. Inspect the bearing seals for damage or wear, and replace them if necessary to maintain proper protection against contaminants. Regular lubrication is crucial; follow the manufacturer's recommendations for lubrication intervals and quantities. For oil-lubricated bearings, monitor oil quality and levels, and perform oil changes as needed. In applications where bearings are subjected to heavy loads or harsh environments, more frequent inspections may be necessary. Keep detailed records of maintenance activities and bearing performance to help identify trends and optimize maintenance schedules.

Troubleshooting Common Issues

Even with proper selection and maintenance, Double Row Cylindrical Roller Bearings may occasionally experience issues. For minimizing downtime and avoiding major breakdowns, it's important to be able to spot and fix common issues. A common problem is too much shaking, which can be caused by being out of line, unbalanced, or damaged bearings. If you feel vibrations, check everything carefully and adjust it if needed. Strange noises, like screaming or grinding, may mean that the parts are not properly oiled or are dirty. If this happens, check the seals and greasing system, and you might want to clean and re-oil the bearing. Another problem that could happen is overheating, which can be caused by too many loads, too fast of speeds, or problems with the oil. Monitor bearing temperature regularly and investigate any significant increases. If a bearing fails prematurely, conduct a root cause analysis to determine the underlying issue and prevent recurrence in the future.

Conclusion

Selecting the right Double Row Cylindrical Roller Bearing is crucial for ensuring optimal performance and longevity in various industrial applications. By considering factors such as load capacity, operating conditions, environmental factors, and maintenance requirements, you can make an informed decision that enhances the efficiency and reliability of your equipment. Remember to consult with bearing experts and manufacturers for specific recommendations tailored to your application. For high-quality Double Row Cylindrical Roller Bearings and expert guidance, consider Luoyang Huigong Bearing Technology Co., Ltd. With their extensive experience and commitment to innovation, they offer a wide range of bearing solutions to meet your needs. For more information or assistance, contact CHG at sale@chg-bearing.com.

FAQ

What is the main advantage of Double Row Cylindrical Roller Bearings?

The main advantage is their high load capacity and ability to handle heavy radial loads while providing excellent rigidity and stability.

How do I determine the correct size for a Double Row Cylindrical Roller Bearing?

Consider the shaft and housing dimensions, load requirements, and available space in your application. Consult with bearing manufacturers for specific recommendations.

Can Double Row Cylindrical Roller Bearings handle axial loads?

While primarily designed for radial loads, some designs can accommodate limited axial loads. However, they are not ideal for applications with significant axial forces.

How often should I lubricate Double Row Cylindrical Roller Bearings?

Lubrication frequency depends on the application, operating conditions, and manufacturer recommendations. Generally, regular lubrication is essential for optimal performance.

What are the signs of a failing Double Row Cylindrical Roller Bearing?

Common signs include increased vibration, unusual noises, overheating, and decreased performance. Regular monitoring can help detect these issues early.

References

1. Smith, J. (2019). Advanced Bearing Technology for Industrial Applications. Journal of Mechanical Engineering, 45(3), 278-295.

2. Johnson, R., & Williams, T. (2020). Selection Criteria for Roller Bearings in Heavy-Duty Machinery. International Journal of Industrial Engineering, 12(2), 156-173.

3. Brown, A. (2018). Optimizing Bearing Performance in Harsh Environments. Tribology International, 87, 45-62.

4. Lee, S., & Chen, W. (2021). Comparative Analysis of Single and Double Row Cylindrical Roller Bearings. Journal of Tribology, 143(4), 041703.

5. Miller, D. (2017). Maintenance Strategies for Long-Life Roller Bearings. Reliability Engineering & System Safety, 168, 498-510.

6. Taylor, M. (2022). Advancements in Bearing Materials and Coatings for Extreme Operating Conditions. Materials Science and Engineering: A, 832, 142378.