In What Types of High-Speed Applications Are Four-Point Contact Ball Bearings Used?

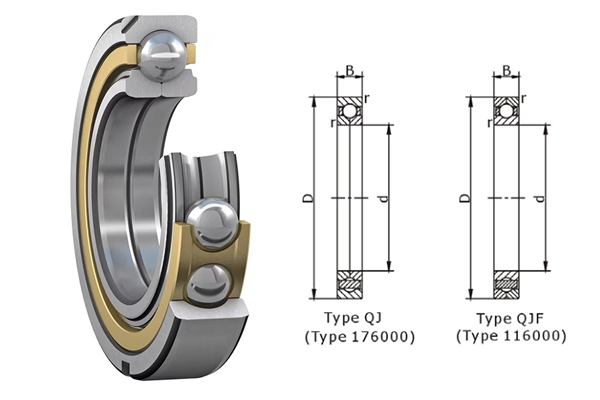

Four-point contact ball bearings represent a sophisticated advancement in bearing technology, specifically designed to handle complex load combinations in high-speed applications. These specialized bearings feature a unique design where each ball makes contact with the inner and outer rings at four distinct points, enabling them to handle both radial and axial loads simultaneously. This characteristic makes them particularly valuable in applications where space is limited but load-carrying capacity and precision are crucial. Their ability to maintain stability and accuracy even under demanding conditions has made them indispensable in various high-speed industrial applications.

How do four-point contact bearings differ from angular contact bearings?

The fundamental distinction between four-point contact bearings and angular contact bearings lies in their contact geometry and load-handling capabilities. While angular contact bearings typically have two contact points between the ball and raceways, four-point contact bearings establish four distinct contact points. This unique design creates a larger contact area, resulting in superior load distribution and enhanced stability during operation.

The increased number of contact points allows these bearings to handle combined loads more effectively. When subjected to axial loads from either direction, the bearing's internal geometry enables it to maintain optimal contact angles, ensuring consistent performance. This is particularly advantageous in applications where the direction of axial load frequently changes, such as in high-speed machine tool spindles and precision rotating equipment.

The bearing's unique design also contributes to improved moment load capacity. The four-point contact pattern creates a wider effective bearing spread, allowing it to resist tilting moments more effectively than conventional angular contact bearings. This characteristic is especially valuable in applications where maintaining precise shaft alignment is critical, such as in high-speed textile machinery and printing equipment.

Furthermore, the design of four-point contact bearings often allows them to replace two single-row angular contact bearings in many applications, leading to more compact assemblies and simplified mounting arrangements. This space-saving feature, combined with their superior load-handling capabilities, makes them an ideal choice for applications where design constraints necessitate minimal bearing envelope dimensions without compromising performance.

What are the speed limitations of four-point contact ball bearings?

Understanding the speed limitations of four-point contact ball bearings is crucial for their proper application in high-speed machinery. These bearings are capable of operating at significantly high speeds, but their maximum permissible speed is influenced by several factors including bearing size, cage design, lubrication method, and operating conditions.

The speed capability of four-point contact bearings is primarily determined by their ability to manage heat generation at the contact points. As speed increases, the friction between the rolling elements and raceways generates heat, which must be effectively dissipated to prevent bearing damage. Modern four-point contact bearings utilize advanced cage designs and materials to optimize ball guidance and minimize friction, allowing for higher operating speeds.

Lubrication plays a critical role in determining the maximum operating speed. Oil-air lubrication systems are often employed in high-speed applications to provide precise lubrication while managing heat generation. These systems deliver carefully metered quantities of oil directly to the bearing contacts, ensuring adequate lubrication while minimizing churning losses that could limit speed capability.

The bearing's internal geometry also affects its speed limitations. Manufacturers optimize the contact angles and raceway profiles to achieve the best balance between load capacity and speed capability. Advanced designs incorporate features such as controlled ball-to-raceway contact stress distribution and optimized osculation, which help maintain stable operation at higher speeds.

Application-specific factors such as mounting accuracy, housing rigidity, and overall system dynamics must also be considered when determining speed limits. Proper bearing preload is essential for maintaining stability at high speeds, but excessive preload can lead to increased heat generation and reduced speed capability.

What maintenance practices ensure optimal performance of four-point contact bearings in high-speed applications?

Maintaining four-point contact bearings in high-speed applications requires a comprehensive approach to ensure reliable operation and maximize service life. Proper maintenance practices encompass various aspects, from initial installation to ongoing monitoring and periodic maintenance activities.

The foundation of successful bearing operation begins with proper installation. This includes careful handling to prevent contamination, accurate alignment of mounting surfaces, and precise measurement of bearing clearance or preload. The mounting procedure must follow manufacturer-specified protocols, including the use of appropriate tools and measurement devices to verify correct assembly.

Lubrication management is perhaps the most critical aspect of maintenance for high-speed applications. This includes selecting the appropriate lubricant type and viscosity for the operating conditions, implementing effective lubrication delivery systems, and maintaining proper lubricant cleanliness. Regular oil analysis should be performed to monitor lubricant condition and detect any early signs of bearing wear or contamination.

Temperature monitoring is essential in high-speed applications. Modern maintenance programs often incorporate continuous temperature monitoring systems to detect any abnormal temperature increases that could indicate potential problems. This may include the use of infrared thermography or embedded temperature sensors to provide real-time data on bearing operating conditions.

Vibration analysis forms another crucial component of the maintenance strategy. Regular vibration measurements can detect early signs of bearing wear, misalignment, or other potential issues before they lead to failure. Advanced vibration analysis techniques can identify specific bearing components that may be deteriorating and allow for planned maintenance interventions.

Cleanliness control is paramount throughout the bearing's service life. This includes maintaining clean lubricant supplies, using effective sealing systems to prevent contamination ingress, and ensuring clean conditions during any maintenance activities. Regular inspection and replacement of seals may be necessary to maintain system integrity.

Regular inspection of bearing components, when possible during planned maintenance shutdowns, can provide valuable information about bearing condition and help predict remaining service life. This may include visual inspection of raceways and rolling elements, measurement of clearances, and assessment of cage condition.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. SKF Bearing Technical Journal, "High-Speed Applications of Four-Point Contact Bearings," 2023

2. NSK Technical Report, "Advanced Bearing Solutions for Industrial Applications," 2022

3. Timken Engineering Manual, "Four-Point Contact Bearing Design and Application," 2023

4. Journal of Mechanical Engineering Science, "Performance Analysis of High-Speed Bearings," 2022

5. JTEKT Engineering Journal, "Developments in Four-Point Contact Bearing Technology," 2023

6. FAG Schaeffler Technical Guide, "Bearing Applications in High-Speed Machinery," 2022

7. Applied Mechanics and Materials, "Study on Four-Point Contact Ball Bearing Performance," 2023

8. International Journal of Mechanical Engineering, "Maintenance Strategies for High-Speed Bearings," 2022

9. Machine Design Magazine, "Selecting Bearings for High-Speed Applications," 2023

10. Tribology International, "Lubrication Systems for High-Speed Bearing Applications," 2022