How Do Type C Thin Section Bearings Compare To Other Types?

Type C thin section bearings are a specialized type of bearing designed for applications where space is at a premium. These bearings offer unique advantages in terms of size, weight, and performance compared to other bearing types. In this blog post, we'll explore the characteristics of Type C thin section bearings and how they stack up against other bearing options, helping you determine if they're the right choice for your specific application.

What are the key features of Type C thin section bearings?

Type C thin section bearings are characterized by their slim profile and unique design. These bearings feature a cross-section that remains constant regardless of bore diameter, which sets them apart from conventional bearings. The "C" in Type C refers to the bearing's cross-sectional shape, which resembles the letter C.

Key features of Type C thin section bearings include:

1. Compact design: Type C bearings have a much thinner cross-section compared to standard bearings, making them ideal for space-constrained applications. This slim profile allows for a larger bore diameter without increasing the overall bearing size.

2. Lightweight construction: Due to their reduced material usage, Type C bearings are significantly lighter than their conventional counterparts. This weight reduction can be crucial in applications where every gram matters, such as aerospace or high-speed machinery.

3. High rigidity: Despite their thin profile, Type C bearings offer excellent rigidity. This is achieved through precise manufacturing techniques and the use of high-quality materials.

4. Versatility: Type C bearings can be used in various configurations, including single bearings, duplex pairs, or even larger bearing assemblies. This flexibility makes them suitable for a wide range of applications.

5. Low friction: The design of Type C bearings allows for reduced friction, which can lead to improved efficiency and lower operating temperatures in many applications.

These features make Type C thin section bearings an attractive option for engineers and designers working on projects where space and weight are critical factors. However, it's essential to consider the specific requirements of your application when deciding if Type C bearings are the best choice.

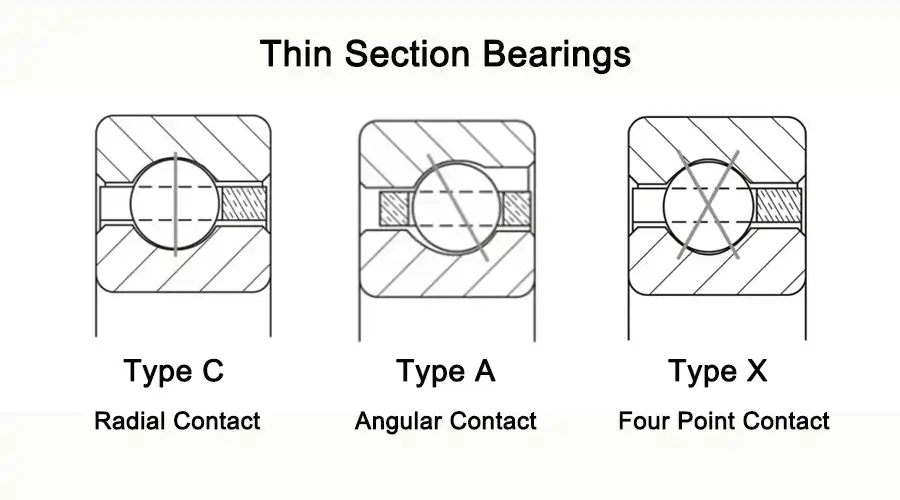

How do Type C thin section bearings differ from Types A and X?

When discussing thin section bearings, it's important to understand that there are three main types: A, B, and C. Each type has its own unique characteristics and advantages, making them suitable for different applications. Let's explore how Type C bearings differ from Types A and B:

1. Cross-sectional shape:

- Type A: Has a rectangular cross-section with rounded corners.

- Type B: Features a Gothic arch outer race and a rectangular inner race.

- Type C: Has a C-shaped cross-section, with both the inner and outer races having a curved profile.

2. Radial section height:

- Type A: Maintains a constant radial section height regardless of bore diameter.

- Type B: The radial section height increases slightly as the bore diameter increases.

- Type C: Like Type A, it maintains a constant radial section height across all bore diameters.

3. Load capacity:

- Type A: Offers the highest load capacity among the three types due to its rectangular cross-section.

- Type B: Provides a balance between load capacity and moment stiffness.

- Type C: Has the lowest load capacity but offers the highest moment stiffness.

4. Moment stiffness:

- Type A: Has the lowest moment stiffness of the three types.

- Type B: Offers improved moment stiffness compared to Type A.

- Type C: Provides the highest moment stiffness, making it ideal for applications requiring high precision and rigidity.

5. Ease of installation:

- Type A: Generally the easiest to install due to its simple rectangular cross-section.

- Type B: Requires more care during installation due to its Gothic arch outer race.

- Type C: Can be more challenging to install due to its C-shaped cross-section, but offers advantages in terms of self-alignment.

6. Suitability for different loads:

- Type A: Best suited for applications with primarily radial loads.

- Type B: Good for applications with combined radial and axial loads.

- Type C: Excels in applications with moment loads and where high stiffness is required.

7. Space efficiency:

- Type A: Offers good space efficiency but may require more radial space than Type C.

- Type B: Similar to Type A in terms of space efficiency.

- Type C: Provides the best space efficiency, allowing for the largest possible bore diameter in a given envelope.

When choosing between Type C and other thin section bearing types, it's crucial to consider the specific requirements of your application. While Type C bearings offer superior moment stiffness and space efficiency, they may not always be the best choice if high load capacity or cost-effectiveness is your primary concern.

Engineers and designers should carefully evaluate factors such as load types, space constraints, precision requirements, and budget when deciding between Type C and other thin section bearing options. In many cases, the unique advantages of Type C bearings, such as their high moment stiffness and compact design, make them the ideal choice for applications in robotics, aerospace, and precision instruments where these characteristics are critical.

What are the advantages of using Type C thin section bearings in robotics applications?

Robotics is one of the most prominent fields where Type C thin section bearings have found widespread use. The unique characteristics of these bearings make them particularly well-suited for the demands of modern robotic systems. Let's explore the advantages of using Type C thin section bearings in robotics applications:

1. Space-saving design:

Robotics often involves complex mechanisms that need to be packed into compact spaces. The slim profile of Type C bearings allows for more efficient use of available space. This is particularly beneficial in robotic arms and joints, where multiple bearings may need to be stacked or placed in close proximity. The space-saving design enables engineers to create more compact and lightweight robotic systems without compromising on functionality.

2. High moment stiffness:

One of the most significant advantages of Type C bearings in robotics is their superior moment stiffness. In robotic applications, precision and stability are crucial. The high moment stiffness of Type C bearings helps to minimize deflection under load, ensuring that robotic arms and joints maintain their intended position even when subjected to various forces. This characteristic is essential for applications requiring high accuracy, such as in assembly lines, surgical robots, or precision manufacturing equipment.

3. Lightweight construction:

Weight is a critical factor in robotics, especially for mobile robots or robotic arms that need to move quickly and efficiently. The lightweight nature of Type C bearings contributes to overall weight reduction in robotic systems. This allows for faster acceleration and deceleration, improved energy efficiency, and reduced wear on other components such as motors and actuators.

4. High-speed capability:

Many robotic applications require rapid movements and high-speed rotations. Type C bearings, with their low friction characteristics and lightweight design, are well-suited for high-speed operations. This capability allows robots to perform tasks more quickly and efficiently, increasing overall productivity in industrial settings.

5. Low friction and smooth operation:

The design of Type C bearings results in lower friction compared to many other bearing types. This reduced friction translates to smoother operation, which is crucial for precise robotic movements. Lower friction also means less heat generation, which can be beneficial in sensitive applications or where thermal management is a concern.

6. Versatility in mounting options:

Type C bearings offer flexibility in how they can be mounted and integrated into robotic systems. They can be used in various configurations, including single bearings, duplex pairs, or more complex assemblies. This versatility allows engineers to design innovative solutions for challenging robotic applications, such as multi-axis joints or compact rotary actuators.

7. Improved load distribution:

The curved profile of Type C bearings allows for better load distribution across the bearing elements. This can lead to increased durability and longer service life, which is particularly important in robotics applications where frequent maintenance or replacement can be costly and time-consuming.

While Type C thin section bearings offer numerous advantages for robotics applications, it's important to note that they may not be the best choice for every situation. Factors such as load capacity, cost, and specific application requirements should always be considered when selecting bearings for a robotic system. However, in many cases, the unique combination of compact size, high stiffness, and precision offered by Type C bearings makes them an excellent choice for advancing the capabilities of modern robotics.

As robotics technology continues to evolve, pushing the boundaries of speed, precision, and compactness, Type C thin section bearings are likely to play an increasingly important role in enabling these advancements. Their unique characteristics align well with the demands of cutting-edge robotic systems, making them a valuable component in the ongoing development of more capable, efficient, and versatile robots across various industries.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. SKF. (2024). Thin section bearings.

2. Kaydon Bearings. (2023). Thin Section Bearings.

3. NSK. (2024). Thin-Section Bearings.

4. Schaeffler. (2023). Thin section bearings.

5. RBC Bearings. (2024). Thin Section Bearings.

6. THK. (2023). Thin-Section Bearings.

7. NTN. (2024). Thin-Section Ball Bearings.

8. Timken. (2023). Thin Section Bearings.

9. IKO. (2024). Thin Type Crossed Roller Bearings.

10. AST Bearings. (2023). Thin Section Bearings.