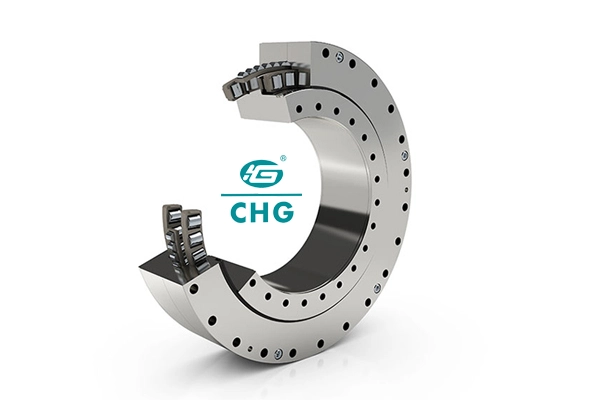

Triple Row Roller Slewing Bearings

2. Feature: The Triple-row Roller Slewing Bearing has three seating rings, which separate the upper, lower and radial raceways. It can specify the loads of each row of rollers. Moreover, its load carrying capacity and it can bear different loads simultaneously. The solid structure and the large axial and radial dimensions.

3. Application: It is applicable to the heavy equipment with large diameter such as bucket-wheel excavator, wheeled crane, ship crane, harbor crane, ladle turrets and heavy-duty mobile crane, etc.

4. Material:50Mn/42CrMo/S48C/42CrMo4/16Mn

What is Triple Row Roller Slewing Bearings?

Triple Row Roller Slewing Bearings are advanced mechanical components designed to support and enable rotational movements in various machinery and equipment. These bearings consist of three rows of rollers, providing exceptional load capacity, stability, and durability. They are crucial for applications requiring high torque and precision, such as construction machinery, lifting equipment, and more.

CHG Bearing: Your Expert in Triple Row Roller Slewing Bearings

At CHG Bearing, we are a leading manufacturer and supplier specializing in the slewing bearings. With over 30 years of industry experience, we provide customized solutions to meet diverse working conditions. Our extensive expertise has allowed us to cooperate with many large companies, and our commitment to quality is reflected in our more than 50 invention patents and certifications, including ISO9001 and ISO14001.

Feel free to contact us at sale@chg-bearing.com for more information or to discuss your specific needs.

Technical Specifications

| Specification | Details |

|---|---|

| Bearing Type | Triple Row Roller Slewing Bearing |

| Load Capacity | High load capacity |

| Material | High-strength steel |

| Precision | High precision |

| Corrosion Resistance | Enhanced corrosion resistance |

| Temperature Range | Wide temperature range |

| Customization | Available based on requirements |

Triple Row Roller Slewing Bearings and Benefits

The slewing bearings offer several significant advantages:

- Enhanced Load Capacity: With three rows of rollers, these bearings can support heavier loads and endure higher stresses compared to single-row bearings.

- Improved Stability: The design ensures better stability during operation, reducing vibrations and enhancing the overall performance of machinery.

- Durability: Constructed from high-strength materials, these bearings are built to last, even in harsh working environments.

- Versatility: They are suitable for a wide range of applications, from construction and lifting machinery to wind turbines and medical equipment.

Applications

Triple Row Roller Slewing Bearings are used across various industries, including:

- Construction Machinery: In excavators, loaders, and bulldozers, providing rotational support and load-bearing capabilities.

- Lifting Machinery: Essential for tower cranes, gantry cranes, and truck cranes to facilitate smooth rotation.

- Wind Power Generation: Supporting the rotating parts of wind turbines to align with wind direction.

- Oil Drilling: Ensuring stable operation of drilling rigs under high loads.

- Military Equipment: Enhancing the maneuverability of tanks and armored vehicles.

- Port Terminals: Improving the efficiency of gantry cranes and other loading equipment.

- Agricultural Machinery: Facilitating rotation in harvesters and tractors.

- Medical Equipment: Assisting in the rotation of imaging devices for better operational ease.

- Amusement Facilities: Providing smooth rotation in carousels and Ferris wheels.

- Aerospace: Supporting rotational components in satellites and rockets.

- Other Fields: Including material processing machinery, transportation machinery, and automated production lines.

Installation Guide

- Preparation: Ensure the mounting surfaces are clean, smooth, and free from debris.

- Alignment: Align the slewing bearing accurately with the housing to avoid misalignment issues.

- Securing: Tighten the mounting bolts evenly in a crisscross pattern to achieve uniform pressure.

- Lubrication: Apply the recommended lubricant to the bearing before use.

- Inspection: Check for any irregularities in rotation or installation to ensure proper functioning.

Maintenance and Care

To ensure the longevity and optimal performance of your slewing bearings:

- Regular Lubrication: Keep the bearings properly lubricated to prevent wear and tear.

- Inspection: Periodically inspect for signs of damage, corrosion, or excessive wear.

- Cleaning: Clean the bearings and surrounding areas to avoid contamination.

- Alignment Check: Regularly verify that the bearings remain properly aligned.

FAQ

Q: What industries commonly use the slewing bearings? A: They are widely used in construction machinery, lifting equipment, wind power generation, oil drilling, military equipment, port terminals, agricultural machinery, medical equipment, amusement facilities, and aerospace.

Q: How do I choose the right Triple Row Roller Slewing Bearing for my application? A: Consider factors such as load capacity, operating environment, and precision requirements. Consult with experts or suppliers for guidance on the best fit for your needs.

Q: What should I do if I experience issues with my bearings? A: Contact your supplier for technical support. Regular maintenance and timely inspections can help prevent most issues.

Customer Reviews

John D. - Construction Equipment Manager "CHG Bearing's slewing bearings have significantly improved the performance and durability of our excavators. Highly recommended for their quality and reliability."

Sarah L. - Wind Turbine Technician "Exceptional quality and great customer service. The bearings we received from CHG Bearing have been performing flawlessly in our wind turbines."

Contact Us

For more information about our Triple Row Roller Slewing Bearings or to get a quote, please contact us at sale@chg-bearing.com. Our team is here to assist you with any questions and provide expert advice tailored to your needs.

Features

The Triple-row Roller Slewing Bearing has three seating rings, which separate the upper, lower and radial raceways. It can specify the loads of each row of rollers. Moreover, its load carrying capacity and it can bear different loads simultaneously. Due to the solid structure and the large axial and radial dimensions, it is applicable to the heavy equipment with large diameter such as bucket-wheel excavator, wheeled crane, ship crane, harbor crane, ladle turrets and heavy-duty mobile crane, etc.

Note:

1.n1 is the number of holes of lubricant, equally spaced, with oil cup M10×1 JB/T7940.1-JB/ T7940.2

2.The fastening holes n-dn1 and n-dn2 can be replaced by the tapped hole; the tooth width b can be changed to H-h

3.The tangential force of the internal gear is the maximum tangential force; the rating tangential force is the half of the maximum tangential force

4.The addendum modification coefficient of internal teeth is 0.2

Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | Gear data | weight (kg) | |||||||||||||||

Dmm | dmm | Hmm | D1mm | D2mm | n | omm | dmmm | Lmm | n1 | D3mm | d1mm | H1mm | hmm | bmm | x | Mmm | Demm | z | ||

133.25.500 | 634 | 366 | 148 | 598 | 402 | 24 | 18 | M16 | 32 | 474 | 463 | 4 | 0 | 32 | 80 | 0.5 | 5 | 337 | 68 | 224 |

134.25.500 | 6 | 338.4 | 57 | |||||||||||||||||

133.25.560 | 694 | 426 | 148 | 658 | 462 | 24 | 18 | M16 | 32 | 534 | 523 | 1 | 10 | 32 | 80 | 0.5 | 5 | 397 | 80 | 240 |

134.25.560 | 6 | 398.4 | 67 | |||||||||||||||||

133.25.630 | 764 | 496 | 148 | 728 | 532 | 28 | 18 | M16 | 32 | 604 | 593 | 4 | 10 | 32 | 80 | 0.5 | 6 | 458.4 | 77 | 270 |

134.25.630 | 8 | 459.2 | 58 | |||||||||||||||||

133.25.710 | 844 | 576 | 148 | 808 | 612 | 28 | 18 | M16 | 32 | 684 | 673 | 4 | 10 | 32 | 80 | 0.5 | 6 | 536.4 | 90 | 300 |

134.25.710 | 8 | 539.2 | 68 | |||||||||||||||||

133.32.800 | 964 | 636 | 182 | 920 | 680 | 36 | 22 | M20 | 40 | 770 | 759 | 4 | 10 | 40 | 120 | 0.5 | 8 | 595.2 | 75 | 500 |

134.32.800 | 10 | 594 | 60 | |||||||||||||||||

133.32.900 | 1064 | 736 | 182 | 1020 | 780 | 36 | 22 | M20 | 40 | 870 | 859 | 4 | 10 | 40 | 120 | 0.5 | 8 | 691.2 | 87 | 600 |

134.32.900 | 10 | 60 | 70 | |||||||||||||||||

133.32.100 | 1164 | 836 | 182 | 1120 | 880 | 40 | 22 | M20 | 40 | 970 | 959 | 5 | 10 | 40 | 120 | 0.5 | 10 | 784 | 79 | 680 |

134.32.100 | 12 | 784.8 | 66 | |||||||||||||||||

133.32.112 | 1284 | 956 | 182 | 1240 | 1000 | 40 | 22 | M20 | 40 | 1090 | 1079 | 5 | 10 | 40 | 120 | 0.5 | 10 | 904 | 91 | 820 |

134.32.112 | 12 | 904 | 76 | |||||||||||||||||

133.40.125 | 1445 | 1055 | 220 | 1393 | 1107 | 45 | 26 | M24 | 48 | 1213 | 100 | 5 | 10 | 50 | 150 | 0.5 | 12 | 988.8 | 83 | 1200 |

134.40.125 | 14 | 985.6 | 71 | |||||||||||||||||

133.40.140 | 1595 | 1205 | 220 | 1543 | 1257 | 45 | 26 | M24 | 48 | 1363 | 1350 | 5 | 10 | 50 | 150 | 0.5 | 12 | 1145 | 96 | 1300 |

134.40.140 | 14 | 1410 | 82 | |||||||||||||||||

133.40.160 | 1795 | 1405 | 220 | 1743 | 1457 | 48 | 26 | M24 | 48 | 1563 | 1550 | 6 | 10 | 50 | 150 | 0.5 | 14 | 1336 | 96 | 1520 |

134.40.160 | 16 | 1334 | 84 | |||||||||||||||||

133.40.180 | 1995 | 1605 | 220 | 1943 | 1657 | 48 | 26 | M24 | 48 | 1763 | 1750 | 6 | 10 | 50 | 150 | 0.5 | 14 | 1532 | 110 | 1750 |

134.40.180 | 16 | 1526 | 96 | |||||||||||||||||

133.45.200 | 2221 | 1779 | 231 | 2155 | 1845 | 60 | 33 | M30 | 60 | 1967 | 1945 | 6 | 12 | 54 | 160 | 0.5 | 16 | 1702 | 107 | 2400 |

134.45.200 | 18 | 1699 | 95 | |||||||||||||||||

133.45.224 | 2461 | 2019 | 231 | 2395 | 2085 | 60 | 33 | M30 | 60 | 2207 | 2185 | 6 | 12 | 54 | 160 | 0.5 | 16 | 1926 | 121 | 2700 |

134.45.224 | 18 | 1933 | 108 | |||||||||||||||||

133.45.250 | 2721 | 2279 | 231 | 2655 | 2345 | 72 | 33 | M30 | 60 | 2467 | 2445 | 8 | 12 | 54 | 160 | 0.5 | 18 | 2185 | 12 | 3000 |

134.45.250 | 20 | 2188 | 110 | |||||||||||||||||

133.45.280 | 3021 | 2579 | 231 | 2955 | 2645 | 72 | 33 | M30 | 60 | 2767 | 2745 | 8 | 12 | 54 | 160 | 0.5 | 18 | 2491 | 139 | 3400 |

134.45.280 | 20 | 2488 | 125 | |||||||||||||||||

133.50.315 | 3432 | 2868 | 270 | 3342 | 2958 | 72 | 45 | M42 | 84 | 3104 | 3090 | 8 | 12 | 65 | 180 | 0.5 | 20 | 2768 | 139 | 5000 |

134.50.315 | 22 | 2759 | 126 | |||||||||||||||||

131.50.355 | 3832 | 3268 | 270 | 3742 | 3358 | 72 | 45 | M42 | 84 | 3504 | 3490 | 8 | 258 | 65 | 180 | 0.5 | 20 | 3168 | 159 | 5680 |

132.50.355 | 22 | 3155 | 144 | |||||||||||||||||

131.50.400 | 4282 | 3718 | 270 | 4192 | 3808 | 80 | 45 | M42 | 84 | 3954 | 3940 | 8 | 258 | 65 | 180 | 0.5 | 22 | 311 | 165 | 6470 |

132.50.400 | 25 | 3610 | 145 | |||||||||||||||||

131.50.450 | 4782 | 4218 | 270 | 4692 | 4308 | 80 | 45 | M42 | 84 | 4454 | 4440 | 8 | 258 | 65 | 180 | 0.5 | 22 | 4123 | 188 | 7320 |

132.50.450 | 25 | 4110 | 165 | |||||||||||||||||

Features

The Triple-row Roller Slewing Bearing has three seating rings, which separate the upper, lower and radial raceways. It can specify the loads of each row of rollers. Moreover, its load carrying capacity and it can bear different loads simultaneously. Due to the solid structure and the large axial and radial dimensions, it is applicable to the heavy equipment with large diameter such as bucket-wheel excavator, wheeled crane, ship crane, harbor crane, ladle turrets and heavy-duty mobile crane, etc.

Note:

1.n1 is the number of holes of lubricant, equally spaced, with oil cup M10×1 JB/T7940.1-JB/ T7940.2

2.The fastening holes n-dn1 and n-dn2 can be replaced by the tapped hole; the tooth width b can be changed to H-h

Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | weight (kg) | |||||||||||

Dmm | dmm | Hmm | D1mm | D2mm | n | mm | dmmm | Lmm | nl | D3mm | d1mm | H1mm | hmm | ||

130.25.500 | 634 | 366 | 148 | 598 | 402 | 24 | 18 | M16 | 32 | 474 | 463 | 4 | 10 | 32 | 224 |

130.25.560 | 694 | 426 | 148 | 658 | 462 | 24 | 18 | M16 | 32 | 534 | 523 | 4 | 10 | 32 | 240 |

130.25.630 | 764 | 496 | 148 | 728 | 532 | 28 | 18 | M16 | 32 | 604 | 593 | 4 | 10 | 32 | 270 |

130.25.710 | 844 | 576 | 148 | 808 | 612 | 28 | 18 | M16 | 32 | 684 | 673 | 4 | 10 | 32 | 300 |

130.32.800 | 964 | 636 | 182 | 920 | 680 | 36 | 22 | M20 | 40 | 770 | 759 | 4 | 10 | 40 | 500 |

130.32.900 | 1064 | 736 | 182 | 1020 | 780 | 36 | 22 | M20 | 40 | 870 | 859 | 4 | 10 | 40 | 600 |

130.32.1000 | 1164 | 836 | 182 | 1120 | 880 | 40 | 22 | M20 | 40 | 970 | 959 | 5 | 10 | 40 | 680 |

130.32.1120 | 1284 | 956 | 182 | 1240 | 1000 | 40 | 22 | M20 | 40 | 1090 | 1079 | 5 | 10 | 40 | 820 |

130.40.1250 | 1445 | 1055 | 220 | 1393 | 1107 | 45 | 26 | M24 | 48 | 1213 | 1200 | 5 | 10 | 50 | 1200 |

130.40.1400 | 1595 | 1205 | 220 | 1543 | 1257 | 45 | 26 | M24 | 48 | 1363 | 1350 | 5 | 10 | 50 | 1300 |

130.40.1600 | 1795 | 1405 | 220 | 1743 | 1457 | 48 | 26 | M24 | 48 | 1563 | 1550 | 6 | 10 | 50 | 1520 |

130.40.1800 | 1995 | 1605 | 220 | 1943 | 1657 | 48 | 26 | M24 | 48 | 1763 | 1750 | 6 | 10 | 50 | 1750 |

130.45.2000 | 2221 | 1779 | 231 | 2155 | 1845 | 60 | 33 | M30 | 60 | 1967 | 1945 | 6 | 12 | 54 | 2400 |

130.45.2240 | 2461 | 2019 | 231 | 2395 | 2085 | 60 | 33 | M3O | 60 | 2207 | 2185 | 6 | 12 | 54 | 2700 |

130.45.2500 | 2721 | 2279 | 231 | 2655 | 2345 | 72 | 33 | M30 | 60 | 2467 | 2445 | 8 | 12 | 54 | 3000 |

130.45.2800 | 3021 | 2579 | 231 | 2955 | 2645 | 72 | 33 | M30 | 60 | 2767 | 2745 | 8 | 12 | 54 | 3400 |

130.50.3150 | 3432 | 2868 | 270 | 3342 | 2958 | 72 | 45 | M42 | 84 | 3104 | 3090 | 8 | 12 | 65 | 5000 |

130.50.3550 | 3832 | 3268 | 270 | 3742 | 3358 | 72 | 45 | M42 | 84 | 3504 | 3490 | 8 | 258 | 65 | 5680 |

130.05.4000 | 4282 | 3718 | 270 | 4192 | 3808 | 80 | 45 | M42 | 84 | 3954 | 3940 | 8 | 258 | 65 | 6470 |

130.50.4500 | 4782 | 4218 | 270 | 4692 | 4308 | 80 | 45 | M42 | 84 | 4454 | 4440 | 8 | 258 | 65 | 7320 |

Features

The Triple-row Roller Slewing Bearing has three seating rings, which separate the upper, lower and radial raceways. It can specify the loads of each row of rollers. Moreover, its load carrying capacity and it can bear different loads simultaneously. Due to the solid structure and the large axial and radial dimensions, it is applicable to the heavy equipment with large diameter such as bucket-wheel excavator, wheeled crane, ship crane, harbor crane, ladle turrets and heavy-duty mobile crane, etc.

Note:

1.n1 is the number of holes of lubricant, equally spaced, with oil cup M10×1 JB/T7940.1-JB/ T7940.2

2.The fastening holes n-dn1 and n-dn2 can be replaced by the tapped hole; the tooth width b can be changed to H-h

3.The tangential force of the internal gear is the maximum tangential force; the rating tangential force is the half of the maximum tangential force

4.The addendum modification coefficient of internal teeth is 0.2

| Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | Gear data | weight (kg) | |||||||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | omm | dmmm | Lmm | n1 | D3mm | d1mm | H1mm | hmm | bmm | x | Mmm | Demm | z | ||

| 131.25.500 | 634 | 366 | 148 | 598 | 402 | 24 | 18 | M16 | 32 | 537 | 526 | 4 | 138 | 32 | 80 | 0.5 | 5 | 664 | 130 | 224 |

| 132.25.500 | 6 | 664.8 | 108 | |||||||||||||||||

| 131.25.560 | 694 | 426 | 148 | 658 | 462 | 24 | 18 | M16 | 32 | 597 | 586 | 4 | 138 | 32 | 80 | 0.5 | 5 | 724 | 142 | 240 |

| 132.25.560 | 6 | 724.8 | 118 | |||||||||||||||||

| 131.25.630 | 764 | 496 | 148 | 728 | 532 | 28 | 18 | M16 | 32 | 667 | 656 | 4 | 138 | 32 | 80 | 0.5 | 6 | 808.8 | 132 | 270 |

| 132.25.630 | 8 | 806.4 | 98 | |||||||||||||||||

| 131.25.710 | 844 | 576 | 148 | 808 | 612 | 28 | 18 | M16 | 32 | 747 | 736 | 4 | 138 | 32 | 80 | 0.5 | 6 | 886.8 | 145 | 300 |

| 132.25.710 | 8 | 886.4 | 108 | |||||||||||||||||

| 131.32.800 | 964 | 636 | 182 | 920 | 680 | 36 | 22 | M20 | 40 | 841 | 830 | 4 | 172 | 40 | 120 | 0.5 | 8 | 1006.4 | 123 | 500 |

| 132.32.800 | 10 | 1008 | 98 | |||||||||||||||||

| 131.32.900 | 1064 | 736 | 182 | 1020 | 780 | 36 | 22 | M20 | 40 | 941 | 930 | 4 | 172 | 40 | 120 | 0.5 | 8 | 1102.4 | 135 | 600 |

| 132.32.900 | 10 | 1108 | 108 | |||||||||||||||||

| 131.32.1000 | 1164 | 836 | 182 | 1120 | 880 | 40 | 22 | M20 | 40 | 1041 | 1030 | 5 | 172 | 40 | 120 | 0.5 | 10 | 1218 | 119 | 680 |

| 132.32.1000 | 12 | 1221.6 | 99 | |||||||||||||||||

| 131.32.1120 | 1284 | 956 | 182 | 1240 | 1000 | 40 | 22 | M20 | 40 | 1161 | 1150 | 5 | 172 | 40 | 120 | 0.5 | 10 | 1338 | 131 | 820 |

| 132.32.1120 | 12 | 1341.6 | 109 | |||||||||||||||||

| 131.40.1250 | 1445 | 1055 | 220 | 1393 | 1107 | 45 | 26 | M24 | 48 | 1300 | 1287 | 5 | 210 | 50 | 150 | 0.5 | 12 | 150.6 | 123 | 1200 |

| 132.40.1250 | 14 | 1509.2 | 105 | |||||||||||||||||

| 131.40.1400 | 1595 | 1205 | 220 | 1543 | 1257 | 45 | 26 | M24 | 48 | 1450 | 1437 | 5 | 210 | 50 | 150 | 0.5 | 12 | 1665.6 | 136 | 1300 |

| 132.40.1400 | 14 | 1663.2 | 116 | |||||||||||||||||

| 131.40.1600 | 1795 | 1405 | 220 | 1743 | 1457 | 48 | 26 | M24 | 48 | 1650 | 1637 | 6 | 210 | 50 | 150 | 0.5 | 14 | 1873.2 | 131 | 1520 |

| 132.40.1600 | 16 | 1868.8 | 114 | |||||||||||||||||

| 131.40 1800 | 1995 | 1605 | 220 | 1943 | 1657 | 48 | 26 | M24 | 48 | 1850 | 1837 | 6 | 210 | 50 | 150 | 0.5 | 14 | 2069.2 | 145 | 1750 |

| 132.40.1800 | 16 | 2076.8 | 127 | |||||||||||||||||

| 131.45.2000 | 2221 | 1779 | 231 | 2155 | 1845 | 60 | 33 | M30 | 60 | 2055 | 2033 | 6 | 219 | 54 | 160 | 0.5 | 16 | 2300.8 | 141 | 2400 |

| 132.45.2000 | 18 | 2300.4 | 125 | |||||||||||||||||

| 131.45.2240 | 2461 | 2019 | 231 | 2395 | 2085 | 60 | 33 | M30 | 60 | 2295 | 2273 | 6 | 219 | 54 | 160 | 0.5 | 16 | 2556.8 | 157 | 2700 |

| 132.45.2240 | 18 | 2552.4 | 139 | |||||||||||||||||

| 131.45.2500 | 2721 | 2279 | 231 | 2655 | 2345 | 72 | 33 | M30 | 60 | 2555 | 2533 | 8 | 219 | 54 | 160 | 0.5 | 18 | 2822.4 | 154 | 3000 |

| 132.45.2500 | 20 | 2816 | 138 | |||||||||||||||||

| 131.45.2800 | 3021 | 2579 | 231 | 2955 | 2645 | 72 | 33 | M30 | 60 | 2855 | 2833 | 8 | 219 | 54 | 160 | 0.5 | 18 | 3110.4 | 170 | 3400 |

| 132.45.2800 | 20 | 3116 | 153 | |||||||||||||||||

| 131.50.3150 | 3432 | 2868 | 270 | 3342 | 2958 | 72 | 45 | M42 | 84 | 3213 | 3196 | 8 | 258 | 65 | 180 | 0.5 | 20 | 3536 | 174 | 50000 |

| 132.50.3150 | 22 | 3537.6 | 158 | |||||||||||||||||

| 131.50.3550 | 3832 | 3268 | 270 | 3742 | 3358 | 72 | 45 | M42 | 84 | 3613 | 3596 | 8 | 258 | 65 | 180 | 0.5 | 22 | 3936 | 194 | 5680 |

| 132.50.3550 | 22 | 393.6 | 176 | |||||||||||||||||

| 131.50.4000 | 4282 | 3718 | 270 | 4192 | 3808 | 80 | 45 | M42 | 84 | 4063 | 4046 | 8 | 258 | 65 | 180 | 0.5 | 22 | 4395.6 | 197 | 6470 |

| 132.50.4000 | 25 | 4395 | 173 | |||||||||||||||||

| 131.50.4500 | 4782 | 4218 | 270 | 4692 | 4308 | 80 | 45 | M42 | 84 | 4563 | 4546 | 8 | 258 | 65 | 180 | 0.5 | 22 | 4901.6 | 220 | 7320 |

| 132.50.4500 | 25 | 4895 | 193 | |||||||||||||||||

YOU MAY LIKE

VIEW MOREThree Row Roller Slewing Bearing

VIEW MOREThree Row Roller Slewing Bearing VIEW MOREFour-Point Contact Ball Slewing Bearings

VIEW MOREFour-Point Contact Ball Slewing Bearings VIEW MORERoller Slewing Bearing

VIEW MORERoller Slewing Bearing VIEW MOREExternal Gear Slewing Bearing

VIEW MOREExternal Gear Slewing Bearing VIEW MORESlewing Ring Bearing With External Gear

VIEW MORESlewing Ring Bearing With External Gear VIEW MORETower Crane Slewing Bearing

VIEW MORETower Crane Slewing Bearing VIEW MOREDouble Row Ball Slewing Bearing

VIEW MOREDouble Row Ball Slewing Bearing VIEW MOREFour Point Contact Ball Slewing Bearing

VIEW MOREFour Point Contact Ball Slewing Bearing