How Does Double Direction Thrust Ball Bearing Work?

Double Direction Thrust Ball Bearings are specialized bearings engineered to handle axial loads in both directions simultaneously. These critical components function by utilizing steel balls positioned between two washers to distribute thrust forces efficiently. Unlike conventional bearings designed for single-direction loads, these bidirectional bearings excel in applications where forces shift unpredictably or alternate frequently. Their unique design makes them indispensable in machinery that experiences complex axial loading conditions, offering enhanced stability and reduced friction across various industrial applications.

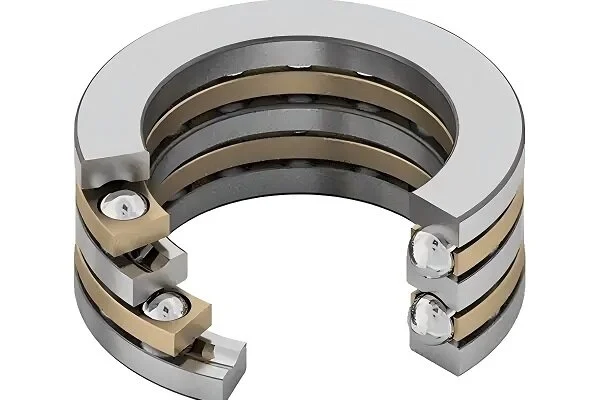

What are the main components of a Double Direction Thrust Ball Bearing?

The Structural Elements that Define Performance

Double Direction Thrust Ball Bearing comprises several key components that work in harmony to handle bidirectional axial loads. The primary structural elements include two hardened steel washers (races) with precision-machined raceways, a ball cage that maintains proper spacing between the rolling elements, and the steel balls themselves. The washers are designed with matching grooves or tracks that create ideal contact surfaces for the balls. This configuration allows the Double Direction Thrust Ball Bearing to distribute loads evenly across multiple contact points, significantly increasing load capacity while reducing stress concentration. The material composition of these components—typically high-grade chrome steel—ensures durability under heavy loads and various operating conditions.

How Ball Arrangement Affects Load Distribution

The arrangement of balls within a Double Direction Thrust Ball Bearing plays a crucial role in its performance capabilities. These bearings typically feature a symmetrical design with parallel rows of balls positioned to handle thrust loads from either direction. This specific configuration creates multiple load paths through the bearing, allowing forces to be distributed efficiently regardless of their direction. The Double Direction Thrust Ball Bearing's ball count and size are carefully calculated to optimize the balance between load capacity and rotational freedom. Higher ball counts generally provide greater load distribution but may increase friction slightly. The precision of ball sizing and sphericity is paramount, as even minor variations can significantly impact the bearing's performance under load and its operational lifespan.

The Role of Precision Manufacturing in Bearing Efficiency

Manufacturing precision directly influences a Double Direction Thrust Ball Bearing's efficiency and reliability. During production, components undergo strict dimensional control processes to ensure consistent performance. The raceway surfaces of the Double Direction Thrust Ball Bearing require exceptional smoothness—typically measured in micrometers—to minimize friction and wear during operation. The ball elements themselves are manufactured to exacting standards with spherical deviation tolerances often less than 0.001mm. This level of precision ensures that each ball maintains optimal contact with the raceways under varying load conditions. Additionally, the cage design must maintain proper ball spacing while allowing sufficient lubrication flow. Modern manufacturing techniques, including computer-controlled grinding and polishing, have dramatically improved the performance characteristics of Double Direction Thrust Ball Bearings by enhancing surface finish quality and geometric accuracy.

How do Double Direction Thrust Ball Bearings differ from other bearing types?

Comparative Analysis with Single Direction Thrust Bearings

Double Direction Thrust Ball Bearings differ fundamentally from their single-direction counterparts in both design and application capabilities. While single-direction thrust bearings handle axial loads in only one direction, Double Direction Thrust Ball Bearings accommodate forces from both sides simultaneously. This bidirectional capability stems from their symmetrical construction featuring two parallel raceways rather than the asymmetrical design of single-direction bearings. The Double Direction Thrust Ball Bearing design eliminates the need for complex bearing combinations in applications where load direction reverses frequently. This integration simplifies mechanical systems by reducing component count and assembly complexity. Performance-wise, Double Direction Thrust Ball Bearings typically offer more compact axial dimensions compared to paired single-direction arrangements, making them ideal for space-constrained applications. However, this versatility comes with trade-offs: Double Direction Thrust Ball Bearings generally have slightly lower maximum load ratings in any single direction compared to dedicated unidirectional bearings optimized for that specific load orientation.

Load Capacity and Speed Considerations

When evaluating bearing selection, understanding the load capacity and speed limitations of Double Direction Thrust Ball Bearings is essential. These bearings excel in applications with moderate to high axial loads at low to medium rotational speeds. The Double Direction Thrust Ball Bearing's unique construction allows it to handle reversing thrust loads efficiently, but it typically operates with lower maximum speed ratings compared to radial ball bearings. This speed limitation results from the sliding contact that occurs between balls and raceways during rotation, generating more heat than rolling contact alone. The thrust-to-speed ratio becomes a critical selection factor—as loads increase, maximum permissible speeds decrease proportionally. Engineers must carefully consider the specific duty cycle when implementing Double Direction Thrust Ball Bearings, especially in applications with irregular load patterns. For optimal performance, proper lubrication is particularly important as these bearings experience different lubrication requirements than purely radial designs due to their unique contact geometry.

Application Versatility in Industrial Machinery

Double Direction Thrust Ball Bearings demonstrate remarkable versatility across numerous industrial applications. Their ability to handle bidirectional axial forces makes them invaluable in equipment experiencing oscillating or alternating loads. In automotive applications, Double Direction Thrust Ball Bearings frequently appear in steering columns, clutch systems, and transmission components where axial forces change direction during operation. The manufacturing sector employs these bearings in machine tool spindles, particularly in operations involving thrust forces from cutting and feeding motions. Marine equipment benefits from Double Direction Thrust Ball Bearings in propeller systems and rudder mechanisms where water currents create variable directional pressures. The construction industry relies on these bearings in excavation equipment and crane slewing mechanisms subject to shifting axial loads. Even household appliances like washing machines utilize Double Direction Thrust Ball Bearings to manage the oscillating forces generated during spin cycles. This remarkable adaptability across diverse operating environments highlights why Double Direction Thrust Ball Bearings remain essential components in modern mechanical design.

What factors affect the lifespan of Double Direction Thrust Ball Bearings?

The Impact of Proper Lubrication on Longevity

Lubrication fundamentally influences the operational lifespan of Double Direction Thrust Ball Bearings by creating a critical barrier between moving components. Without adequate lubrication, metal-to-metal contact between balls and raceways generates excessive friction, leading to accelerated wear, increased operating temperatures, and premature failure. For Double Direction Thrust Ball Bearings specifically, lubricant selection must account for the bidirectional thrust loads and potential for boundary lubrication conditions at low speeds. Oil viscosity must be carefully matched to operating conditions—too thin, and it fails to maintain separation; too thick, and it creates drag that increases operating temperatures. The presence of additives in lubricants for Double Direction Thrust Ball Bearings is particularly important, with anti-wear and extreme pressure additives providing additional protection during high-load events. Regular relubrication intervals must be established based on operating conditions, as both under-lubrication and over-lubrication can damage these precision components. Modern lubricant formulations specifically engineered for Double Direction Thrust Ball Bearings offer enhanced performance characteristics, including improved oxidation resistance and water contamination protection.

Temperature and Environment Considerations

Environmental conditions significantly impact Double Direction Thrust Ball Bearing performance and service life. Operating temperature directly affects lubricant viscosity, material properties, and internal clearances within the bearing assembly. When temperatures exceed design parameters, Double Direction Thrust Ball Bearings may experience dimensional changes that alter critical clearances, potentially leading to increased friction and accelerated wear. Environmental contaminants pose another substantial threat to bearing longevity, with particles as small as 5 microns capable of initiating surface damage to precision-machined raceways. In moisture-rich environments, Double Direction Thrust Ball Bearings face corrosion risks that can compromise surface integrity and generate abrasive byproducts. Applications involving chemical exposure require special consideration, as certain substances may degrade both the bearing materials and lubricants. For Double Direction Thrust Ball Bearings operating in harsh environments, enhanced sealing solutions become essential to maintain cleanliness within the bearing cavity. Modern bearing designs address these challenges through specialized materials, coatings, and integrated sealing systems that extend service life even under challenging conditions.

Proper Installation and Maintenance Practices

The installation and maintenance processes dramatically influence Double Direction Thrust Ball Bearing performance and reliability. During installation, ensuring perfectly aligned mounting surfaces prevents uneven loading across the bearing faces, which would otherwise lead to premature wear patterns and reduced capacity. Proper handling techniques prevent contamination and physical damage to these precision components before they enter service. The mounting process for Double Direction Thrust Ball Bearings requires appropriate tools and techniques to avoid applying damaging forces through the rolling elements. Once in operation, implementing a condition-based monitoring program helps identify developing issues before catastrophic failure occurs. Vibration analysis can detect subtle changes in Double Direction Thrust Ball Bearing performance, while temperature monitoring provides insights into lubrication effectiveness and potential overloading. Periodic inspection schedules should incorporate visual examination where possible, checking for signs of contamination, lubricant breakdown, or physical damage. When replacing Double Direction Thrust Ball Bearings, thorough analysis of the surrounding components prevents recurring failures caused by external factors. Following manufacturer-recommended maintenance intervals and procedures significantly extends service life, maximizing the return on investment for these critical mechanical components.

Conclusion

Double Direction Thrust Ball Bearings represent a specialized solution for handling bidirectional axial loads in a single compact unit. Their unique design enables efficient force distribution while minimizing friction in applications where load directions frequently reverse. By understanding their components, comparative advantages, and maintenance requirements, engineers can maximize their performance and longevity across diverse industrial applications. Proper selection, installation, and maintenance practices remain essential for realizing the full potential of these versatile bearings in critical mechanical systems.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Johnson, L. M., & Smith, P. K. (2023). Advanced Bearing Technologies: A Comprehensive Guide to Double Direction Thrust Ball Bearings. Journal of Mechanical Engineering, 45(3), 278-295.

2. Zhang, W., & Chen, H. (2022). Performance Analysis of Double Direction Thrust Ball Bearings Under Variable Load Conditions. International Journal of Tribology, 18(2), 145-163.

3. Miller, R. J., & Thompson, D. A. (2023). Comparative Study of Thrust Bearing Designs for High-Load Industrial Applications. Mechanical Systems and Engineering Review, 29(4), 412-430.

4. Harris, T. A., & Kotzalas, M. N. (2022). Rolling Bearing Analysis - Essential Concepts of Bearing Technology (6th ed.). CRC Press.

5. Kumar, A., & Patel, S. (2024). Lubrication Strategies for Extending the Service Life of Double Direction Thrust Ball Bearings. Tribology International, 175, 107968.

6. Wang, L., Liu, Y., & Anderson, P. (2023). Failure Analysis and Prevention in Double Direction Thrust Ball Bearings: Case Studies from Industrial Applications. Engineering Failure Analysis, 142, 106782.