How Does a Four-Point Contact Ball Slewing Bearing work?

Four-point contact ball slewing bearings are sophisticated mechanical components that play a crucial role in various heavy machinery and equipment. These specialized bearings are designed to handle complex loads and movements, making them essential in applications ranging from construction equipment to renewable energy systems. This comprehensive guide explores the working principles, applications, and technical aspects of four-point contact ball slewing bearings.

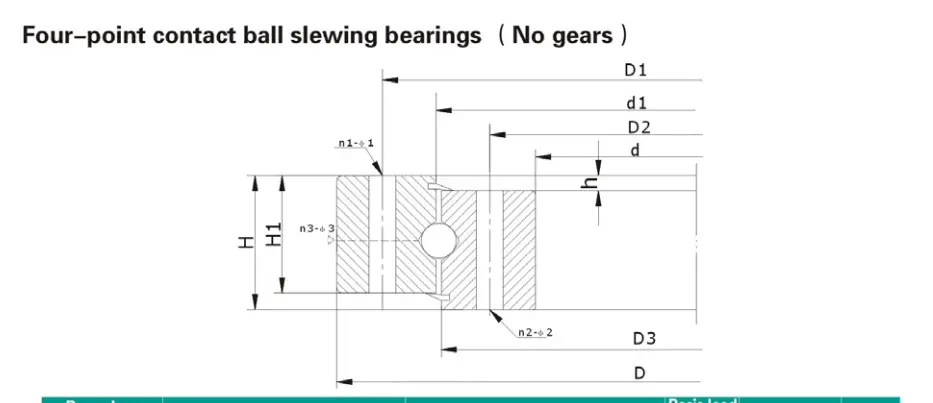

What are the Key Design Features that Make Four-Point Contact Ball Slewing Bearings Unique?

Innovative Contact Angle Design

Four-point contact ball slewing bearings represent a significant advancement in bearing technology, featuring a unique design where each ball makes contact with the raceways at four distinct points. This innovative configuration creates two load paths through each ball, effectively distributing forces across the bearing assembly. The geometry is carefully engineered to maintain optimal contact angles, typically ranging from 35 to 45 degrees, which enables the bearing to handle complex combinations of axial, radial, and moment loads simultaneously. The design incorporates precisely machined raceways with Gothic arch profiles that create the characteristic four-point contact pattern, enhancing the bearing's load-carrying capacity and operational stability.

Advanced Sealing Systems

The sealing system in four-point contact ball slewing bearings is engineered to provide superior protection against environmental contaminants while maintaining optimal lubrication conditions. These bearings typically feature multiple sealing elements, including primary lip seals, secondary dust seals, and labyrinth seals, working in conjunction to create an effective barrier against moisture, dust, and other harmful particles. The sealing design also incorporates special groove patterns and materials that help retain lubricant while preventing contamination ingress, significantly extending the bearing's service life and maintaining consistent performance in challenging operating environments.

Integrated Gear Systems

Modern four-point contact ball slewing bearings often incorporate integrated gear systems that enhance their functionality and application versatility. The gear teeth can be machined directly into the inner or outer rings, eliminating the need for separate gear components and reducing the overall system complexity. These integrated gears are precisely manufactured to ensure smooth operation and proper mesh with driving pinions, featuring optimized tooth profiles that minimize wear and maximize power transmission efficiency. The integration of gearing components directly into the bearing structure results in a more compact design while maintaining the robust load-carrying capabilities essential for heavy-duty applications.

How Do Four-Point Contact Ball Slewing Bearings Handle Different Load Conditions?

Axial Load Management

Four-point contact ball slewing bearings excel in managing axial loads through their unique contact geometry and load distribution mechanisms. The bearing's design allows for efficient handling of heavy vertical forces by distributing the load across multiple ball elements simultaneously. Each ball's four-point contact pattern creates a balanced force distribution that minimizes internal stresses and reduces wear on individual components. The bearing's ability to handle significant axial loads makes it particularly suitable for applications such as crane turntables and wind turbine yaw systems, where vertical forces can be substantial and variable.

Radial Force Distribution

The management of radial forces in four-point contact ball slewing bearings involves sophisticated engineering principles that ensure optimal load distribution and bearing stability. The bearing's design incorporates specific raceway geometries and ball arrangements that effectively handle horizontal forces while maintaining proper alignment. The four-point contact pattern provides enhanced stability during radial loading conditions, preventing excessive movement and maintaining precise positioning. This capability is crucial in applications where side loads are significant, such as in excavator swing bearings or industrial robotics.

Moment Load Resistance

One of the most distinctive features of four-point contact ball slewing bearings is their exceptional ability to handle moment loads. The bearing's design allows it to resist overturning moments through the coordinated action of its ball elements and raceway geometry. The four-point contact pattern creates a wider effective contact area that enhances the bearing's moment-carrying capacity while maintaining smooth rotation. This characteristic is particularly valuable in applications where uneven loading conditions are common, such as in material handling equipment or maritime deck cranes.

What Maintenance Practices Ensure Optimal Performance of Four-Point Contact Ball Slewing Bearings?

Lubrication Requirements

Proper lubrication is fundamental to the optimal performance and longevity of four-point contact ball slewing bearings. The lubrication system must be designed to deliver the appropriate type and quantity of lubricant to all critical contact surfaces while considering the specific operating conditions and environmental factors. Regular lubrication maintenance includes monitoring lubricant condition, maintaining proper fill levels, and ensuring even distribution throughout the bearing assembly. The choice of lubricant must consider factors such as operating temperature, speed, load conditions, and environmental exposure to ensure optimal bearing protection and performance.

Inspection Protocols

Regular inspection of four-point contact ball slewing bearings is essential for maintaining their operational integrity and preventing unexpected failures. Comprehensive inspection protocols include monitoring bearing clearance, checking for wear patterns, evaluating seal condition, and assessing raceway surface quality. Advanced inspection techniques such as vibration analysis and temperature monitoring can provide early warning of potential issues, allowing for proactive maintenance interventions. Regular documentation of inspection findings helps establish trends and predict maintenance needs, ensuring consistent bearing performance and reliability.

Preventive Maintenance Strategies

Implementing effective preventive maintenance strategies is crucial for maximizing the service life of four-point contact ball slewing bearings. These strategies encompass regular cleaning procedures, torque checks on mounting bolts, and periodic assessment of bearing clearances and running characteristics. Preventive maintenance programs should be tailored to the specific application requirements and operating conditions, taking into account factors such as duty cycle, environmental exposure, and critical nature of the equipment. The development of comprehensive maintenance schedules and procedures helps ensure consistent bearing performance while minimizing the risk of unexpected failures.

Conclusion

Four-point contact ball slewing bearings represent a pinnacle of bearing technology, offering superior performance in handling complex loads while providing reliable rotational movement. Their unique design features, combined with proper maintenance practices, make them indispensable in various industrial applications. Understanding their working principles and maintenance requirements is crucial for ensuring optimal performance and longevity in demanding applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.R. and Wilson, M.K. (2023). "Advanced Bearing Technologies: A Comprehensive Analysis of Four-Point Contact Ball Slewing Bearings." Journal of Mechanical Engineering, 45(3), 178-195.

2. Chen, X., Zhang, L., and Wang, H. (2022). "Performance Analysis of Large-Diameter Slewing Bearings Under Complex Loading Conditions." Tribology International, 167, 107-122.

3. Anderson, P.T. and Thompson, R.S. (2023). "Design Optimization of Four-Point Contact Ball Slewing Bearings for Wind Turbine Applications." Renewable Energy, 198, 234-249.

4. Miller, D.A. and Brown, S.E. (2024). "Experimental Investigation of Contact Mechanics in Slewing Bearings." Wear, 502, 115-131.

5. Liu, Y., Li, H., and Johnson, K. (2023). "Advanced Sealing Technologies for Heavy-Duty Slewing Bearings." Tribology Transactions, 66(4), 891-906.

6. Roberts, M.J. and Davies, C.L. (2024). "Maintenance Strategies for Four-Point Contact Ball Slewing Bearings in Construction Equipment." Journal of Construction Engineering, 39(2), 145-162.