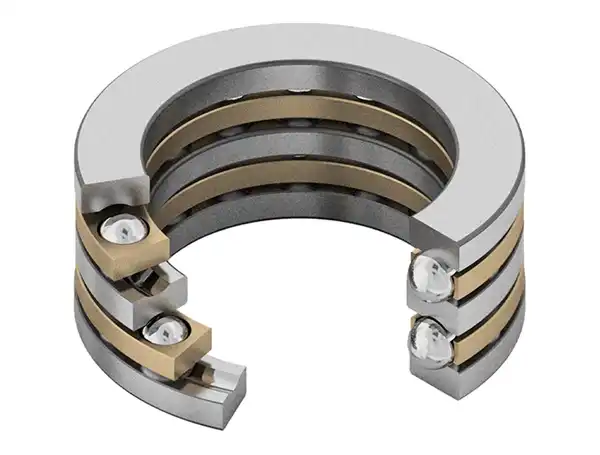

Double Direction Thrust Ball Bearing

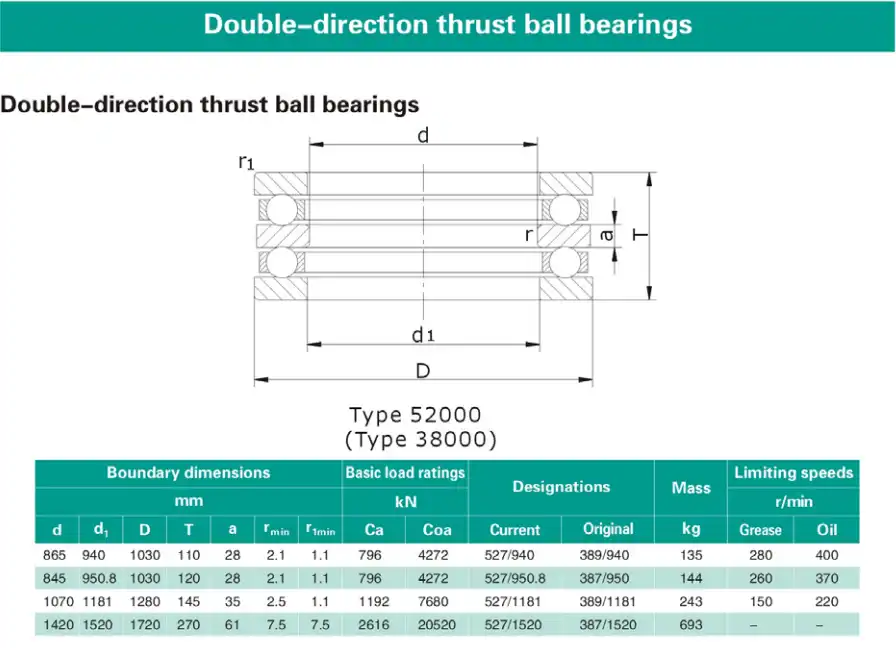

Outer Diameter: 1030-1720mm

Weight: 135-693kg

Type: 52000,38000

Double direction thrust ball bearings consist of three rings, along with two ball and cage assemblies. The two ball and cage assemblies are separated by the shaft washer.

Double direction thrust ball bearings are able to accommodate axial thrust loads in both directions. They are not able to tolerate any amount of radial load.

The balls which are used as rolling elements in this type of bearing enable outstanding performance at the highest speeds.

These bearings have a separable design to facilitate easy mounting, dismounting and bearing inspection. This also means that they are easily interchangeable.

What is a Double Direction Thrust Ball Bearing?

A Double Direction Thrust Ball Bearing is a specialized bearing designed to handle axial loads in both directions. Unlike single-direction thrust ball bearings, which can only manage axial forces in one direction, these bearings are engineered to support load in both orientations, making them ideal for applications requiring bi-directional axial stability. They consist of two washers with raceways and a set of ball assemblies, ensuring smooth operation and minimal friction. This type of bearing is commonly used in high-precision machinery where the load must be supported from multiple directions.

Why Choose CHG Bearing for Double Direction Thrust Ball Bearings?

At CHG Bearing, we pride ourselves on being a leading manufacturer and supplier of Double Direction Thrust Ball Bearings. Here’s why you should consider us for your bearing needs:

Customized Solutions: We understand that every industry has unique requirements. That’s why we offer customized solutions to meet specific working conditions, ensuring that our bearings perform optimally in your machinery.

Industry Experience: With over 30 years of experience, CHG Bearing has partnered with numerous large companies across various industries, providing reliable and high-quality bearings.

Innovation and Quality: We hold more than 50 invention patents and have been certified with ISO9001 for quality management and ISO14001 for environmental management. Our bearings are manufactured under strict quality control, ensuring durability and precision.

Welcome to contact us at sale@chg-bearing.com for more information or to discuss your specific requirements.

Technical Specifications

| Parameter | Specification |

|---|---|

| Bearing Type | Double Direction Thrust Ball Bearing |

| Material | High-grade Steel (Custom options available) |

| Load Capacity | Up to 500 kN |

| Size Range | 50mm to 200mm (ID) |

| Temperature Range | -30°C to 150°C |

| Lubrication | Grease/Oil (Custom options available) |

| Certification | ISO9001, ISO14001 |

Benefits of Double Direction Thrust Ball Bearings

- High Precision: Our bearings are manufactured to high precision standards, ensuring smooth and efficient operation in demanding environments.

- Durability: Designed to withstand harsh conditions, including high temperatures and heavy loads, our bearings offer long service life and reduced maintenance needs.

- Cost-Effective: With their extended lifespan and low maintenance requirements, our bearings offer excellent value for money.

- Customization: We provide tailored solutions to meet the specific needs of your equipment, including size, material, and lubrication customizations.

Applications

Double Direction Thrust Ball Bearings are versatile and used across various industries, including:

- Metallurgical Industry: Essential in large rotating equipment like blast furnaces, rolling mills, and steelmaking equipment.

- Mining Machinery: Commonly used in jaw crushers, impact crushers, vibrating screens, and feeders to handle large impact loads.

- Machinery Manufacturing: Suitable for a range of equipment where axial load support in both directions is critical.

Installation Guide

To ensure optimal performance of them, follow these installation steps:

- Preparation: Clean the housing and shaft to remove any debris or contaminants.

- Alignment: Ensure proper alignment of the bearing with the shaft and housing to avoid uneven load distribution.

- Lubrication: Apply the appropriate lubricant to the bearing. Check manufacturer recommendations for grease or oil types.

- Mounting: Carefully mount the bearing using the correct tools to prevent damage to the bearing components.

- Testing: After installation, run the equipment to verify smooth operation and correct any misalignments if necessary.

Maintenance and Care

Proper maintenance is key to extending the life of your Double Direction Thrust Ball Bearings. Here are some tips:

- Regular Inspection: Periodically check for signs of wear, misalignment, or lubrication issues.

- Re-lubrication: Follow the recommended lubrication schedule based on operating conditions.

- Cleaning: Keep the bearing and surrounding area clean to prevent contamination.

- Replacement: Replace bearings if you notice excessive wear or if they fail to perform as expected.

FAQ

Q1: What makes their different from single-direction bearings?

A1: They can handle axial loads in both directions, providing greater flexibility and stability in applications where load direction may vary.

Q2: Can these bearings be customized for specific applications?

A2: Yes, CHG Bearing offers customization options for size, material, and lubrication to meet the specific needs of your equipment.

Q3: How long do these bearings last?

A3: With proper installation and maintenance, our bearings are designed for long life even in harsh environments.

Q4: What industries commonly use these bearings?

A4: They are widely used in the metallurgical, mining, and machinery manufacturing industries.

Q5: How quickly can CHG Bearing deliver these products?

A5: We offer fast delivery services, and lead times may vary depending on the order size and customization requirements.

Customer Reviews

"We've been using CHG Bearing's Double Direction Thrust Ball Bearings for over a decade, and they've consistently performed beyond expectations. The durability and precision are unmatched." – John D., Production Manager

"CHG Bearing's customization options helped us find the perfect solution for our unique equipment needs. Highly recommend their products and services." – Lisa T., Technical Engineer

Contact Us

For more information or to place an order, please contact us at sale@chg-bearing.com. Our team is ready to assist you with any inquiries and provide tailored solutions for your bearing needs.