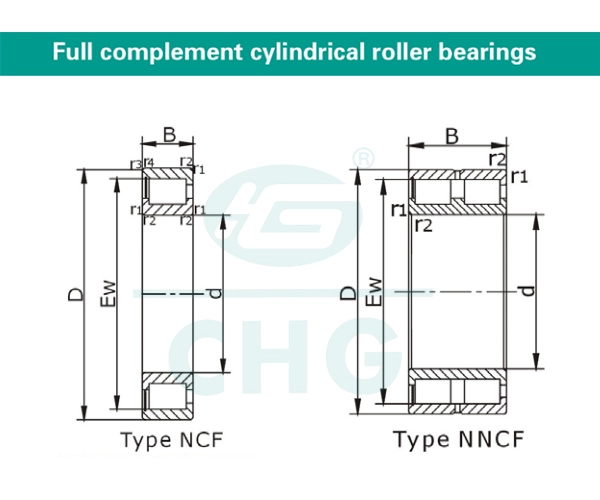

What are Full Complement Cylindrical Roller Bearings?

Full complement cylindrical roller bearings are specialized components designed to handle significant radial loads. Unlike traditional roller bearings, these rely entirely on the rolling elements without a cage, allowing for higher load capacity. Their design is ideal for applications in demanding environments where maximum durability and efficiency are pivotal.

Technical Specifications

Below is a table summarizing the key technical specifications of our cylindrical roller bearings:

| Specification | Details |

|---|---|

| Load Capacity | High |

| Temperature Range | -40°C to +120°C |

| Material | Chrome steel |

| Lubrication Options | Grease/Oil |

| Customization Availability | Size, Structure, Material |

| Compliance | ISO9001, ISO14001 |

Why Choose CHG Bearing?

Expertise and Experience:

Over 30 years of industry-related experience.

Extensive collaboration with numerous large corporations.

Customization and Solutions:

Provide tailored solutions for different working conditions.

Ability to customize size, structure, material, and lubrication methods.

Innovation and Patents:

Holder of more than 50 invention patents.

Continual investment in research and development.

Quality Assurance:

Certified by ISO9001 quality management system.

Certified by ISO14001 environmental management system.

Commitment to meeting international quality standards.

Benefits of Full Complement Cylindrical Roller Bearings

High Load Capacity: The absence of a cage allows more rollers, increasing load capacity.

Durability: Constructed from high-grade steel for extended life and wear resistance.

Customization: Tailored designs meet diverse application requirements across various industries.

Cost-Effectiveness: Competitive pricing while ensuring premium performance and longevity.

Applications

Full complement cylindrical roller bearings are pivotal in sectors like metallurgy and mining:

Metallurgical Industry: Essential in large rotating equipment such as blast furnaces and rolling mills.

Mining Machinery: Used in jaw crushers, impact crushers, vibrating screens, and feeders due to their robust design and high-load capabilities.

Installation Guide

Preparation: Ensure the environment is clean and free of contaminants.

Alignment: Properly align the bearing to avoid misalignment during operation.

Lubrication: Apply the recommended lubricant generously before installation.

Mounting: Utilize appropriate tools to mount the bearing without causing damage.

Maintenance and Care

Regular Inspections: Periodically check for wear and tear.

Lubrication: Maintain adequate lubrication levels to ensure smooth operation.

Environment Control: Keep the operating environment clean to prevent contamination.

FAQ

Q: Can these bearings operate in high temperatures?

A: Yes, they are built to function efficiently between -40°C and +120°C.

Q: Do you offer customization services?

A: Absolutely. We can customize size, structure, material, and lubrication methods to suit specific needs.

Customer Reviews

"Our partnership with CHG Bearing has been invaluable. Their cylindrical roller bearings have remarkably improved the reliability of our equipment."

— John D., Metallurgical Equipment Manager

"Exceptional quality and service! CHG's bearings have significantly reduced our maintenance costs."

— Sarah L., Mining Operations Director

Contact Us

For comprehensive solutions and expert advice on full complement cylindrical roller bearings, please get in touch with us at [sale@chg-bearing.com]. Our team is eager to assist you with all your bearing-related inquiries and ensure your operations run smoothly.

YOU MAY LIKE

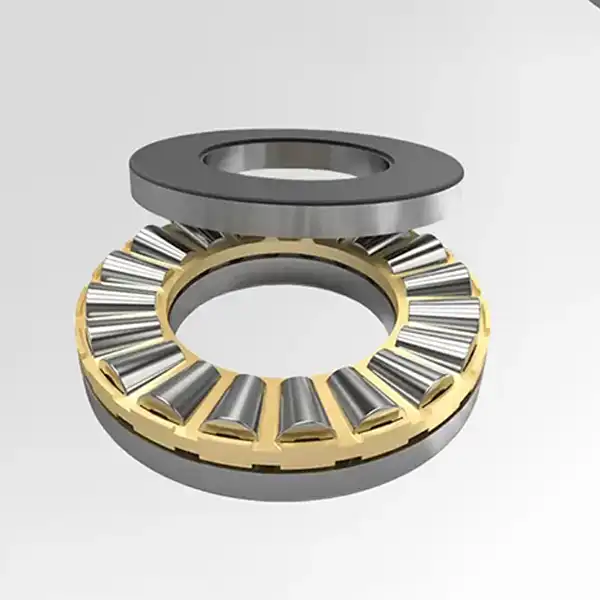

VIEW MORECylindrical Roller Thrust Bearings

VIEW MORECylindrical Roller Thrust Bearings VIEW MORESelf Aligning Tapered Roller Bearing

VIEW MORESelf Aligning Tapered Roller Bearing VIEW MOREHigh Speed Tapered Roller Bearings

VIEW MOREHigh Speed Tapered Roller Bearings VIEW MORESpherical Roller Thrust Bearings

VIEW MORESpherical Roller Thrust Bearings VIEW MOREInch Series Single Row Tapered Roller Bearings

VIEW MOREInch Series Single Row Tapered Roller Bearings VIEW MORETapered Roller Thrust Bearing

VIEW MORETapered Roller Thrust Bearing VIEW MORERoll Neck Bearings

VIEW MORERoll Neck Bearings VIEW MOREThrust Roller Bearing

VIEW MOREThrust Roller Bearing