How Do You Maintain a Four Point Contact Ball Slewing Bearing?

Four point contact ball slewing bearings are critical components in various heavy machinery and equipment, particularly in applications that require rotational movement under heavy loads. These bearings are designed to handle both axial and radial loads simultaneously, making them ideal for use in cranes, excavators, wind turbines, and other large rotating structures. Proper maintenance of these bearings is essential to ensure optimal performance, longevity, and safety of the equipment they support. In this comprehensive guide, we will explore the key aspects of maintaining four point contact ball slewing bearings, including their components, lubrication requirements, and signs of wear.

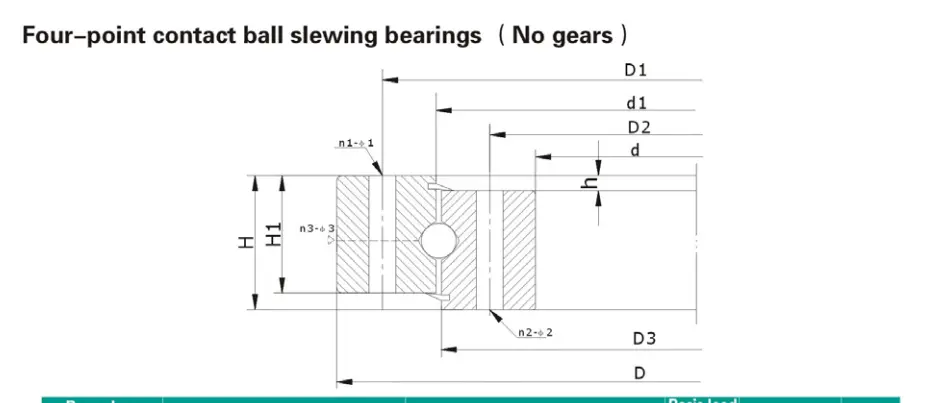

What are the key components of a four point contact ball slewing bearing?

Understanding the key components of a four point contact ball slewing bearing is crucial for effective maintenance. These bearings are complex assemblies designed to distribute loads evenly and facilitate smooth rotational movement. Let's break down the main components and their functions:

1. Outer and Inner Rings: The outer and inner rings form the primary structure of the bearing. The outer ring is typically stationary and attached to the fixed part of the machine, while the inner ring rotates with the moving component. These rings are precision-machined to ensure proper alignment and load distribution.

2. Ball Elements: The ball elements are the heart of the bearing, providing the rolling contact that allows for smooth rotation. In a four point contact design, these balls are arranged in a way that they contact both the inner and outer rings at four points, hence the name. This configuration allows the bearing to handle axial loads from both directions as well as radial loads.

3. Cage or Retainer: The cage, also known as a retainer, keeps the ball elements evenly spaced around the bearing. It prevents the balls from coming into contact with each other, reducing friction and wear. The cage design is critical for maintaining proper ball spacing and ensuring smooth operation.

4. Seals: Seals are vital components that protect the internal parts of the bearing from contamination. They prevent dust, water, and other debris from entering the bearing while also keeping lubricant inside. Proper sealing is essential for prolonging the life of the bearing and maintaining its performance.

5. Raceways: The raceways are the grooved tracks on the inner and outer rings where the balls roll. In a four point contact bearing, these raceways are designed with a specific curvature that allows for the four-point contact of each ball. This design is what gives the bearing its unique load-handling capabilities.

Understanding these components is essential for several reasons. First, it allows maintenance personnel to perform thorough inspections, knowing exactly what to look for and where. Second, it helps in troubleshooting issues that may arise during operation. For example, if unusual noise is detected, understanding the bearing's components can help narrow down the potential sources of the problem.

How often should you lubricate a four point contact ball slewing bearing?

Proper lubrication is arguably the most critical aspect of maintaining a four point contact ball slewing bearing. The frequency of lubrication depends on various factors, including the operating conditions, environment, and the specific recommendations of the bearing manufacturer. However, there are general guidelines and best practices that can help ensure optimal lubrication.

Firstly, it's important to understand that under-lubrication and over-lubrication can both lead to bearing failure. Under-lubrication causes increased friction, heat generation, and wear, while over-lubrication can lead to churning, increased operating temperatures, and potential seal damage. Therefore, striking the right balance is crucial.

For most industrial applications, four point contact ball slewing bearings should be lubricated at regular intervals. As a general rule, many manufacturers recommend re-lubricating the bearing every 100 operating hours or at least once a month, whichever comes first. However, this frequency can vary significantly based on the following factors:

1. Operating Speed: Bearings that operate at higher speeds typically require more frequent lubrication due to increased heat generation and potential for lubricant breakdown.

2. Load Conditions: Heavily loaded bearings may need more frequent lubrication to maintain a proper lubricant film between the rolling elements and raceways.

3. Environmental Conditions: Bearings exposed to harsh environments (high humidity, dust, extreme temperatures) may require more frequent lubrication to counteract contamination and lubricant degradation.

4. Bearing Size: Larger bearings often have more demanding lubrication requirements due to their increased surface area and higher operating loads.

5. Application: The specific application of the bearing can greatly influence lubrication needs. For example, a bearing in a continuously operating wind turbine may have different requirements than one in an intermittently used crane.

To determine the optimal lubrication frequency for your specific application, consider the following steps:

1. Consult the Manufacturer's Guidelines: Always start with the recommendations provided by the bearing manufacturer. They have extensive knowledge of their products and can provide application-specific advice.

2. Implement a Monitoring Program: Regularly monitor the bearing's performance, temperature, and vibration levels. Increases in these parameters may indicate a need for lubrication.

3. Analyze Used Grease: Periodically analyze samples of used grease from the bearing. This can provide insights into the rate of lubricant degradation and help optimize re-lubrication intervals.

4. Use Automatic Lubrication Systems: For critical applications or hard-to-reach bearings, consider installing automatic lubrication systems. These can provide small, frequent doses of lubricant, ensuring consistent lubrication without the risk of over-greasing.

5. Keep Detailed Records: Maintain logs of lubrication activities, including dates, amounts, and types of lubricant used. This information can be invaluable for identifying trends and optimizing maintenance schedules.

In conclusion, while the general recommendation for lubricating four point contact ball slewing bearings is every 100 operating hours or monthly, the actual frequency should be tailored to your specific application and operating conditions. Regular monitoring, analysis, and adherence to manufacturer guidelines will help ensure optimal lubrication practices, contributing to extended bearing life and reliable equipment operation.

What are the signs of wear in a four point contact ball slewing bearing?

Detecting early signs of wear in a four point contact ball slewing bearing is crucial for preventing unexpected failures, reducing downtime, and optimizing maintenance schedules. These bearings are designed for long service life, but like all mechanical components, they are subject to wear over time. Recognizing the signs of wear allows for timely intervention, which can extend the bearing's lifespan and prevent catastrophic failures. Here are the key indicators of wear to watch for:

1. Unusual Noise: One of the earliest and most noticeable signs of wear in a slewing bearing is unusual noise during operation. This can manifest as:

- Grinding: A grinding noise often indicates that the balls or raceways have become damaged or contaminated.

- Clicking or Popping: These sounds may suggest that the balls are no longer running smoothly in their tracks, possibly due to flat spots or surface damage.

- Rumbling: A low, rumbling noise can indicate general wear across the bearing surfaces or potential misalignment.

It's important to note that the normal operating sound of a slewing bearing should be a smooth, consistent noise. Any change in the sound characteristics warrants investigation.

2. Increased Vibration: As wear progresses, you may notice increased vibration in the bearing or the equipment it's supporting. This can be detected through:

- Touch: Placing a hand on the equipment near the bearing can sometimes allow you to feel increased vibration.

- Vibration Analysis: Using specialized vibration analysis equipment can provide more detailed information about the nature and severity of the vibration.

Increased vibration can indicate various issues, including uneven wear of the raceways, damaged balls, or misalignment of the bearing.

3. Irregular Motion: A worn slewing bearing may not rotate as smoothly as it should. Signs of irregular motion include:

- Jerky Movement: The rotation may no longer be smooth, with noticeable jumps or hesitations during operation.

- Increased Torque Requirements: If more force is required to rotate the bearing than previously needed, this could indicate internal wear or misalignment.

- Play or Looseness: Excessive axial or radial play in the bearing can indicate wear in the raceways or rolling elements.

4. Lubricant Contamination: Examining the condition of the lubricant can provide valuable insights into the bearing's health:

- Metal Particles: The presence of metal particles in the grease or oil suggests that wear is occurring within the bearing.

- Color Changes: Darkening of the lubricant or the presence of a metallic sheen can indicate contamination or oxidation.

- Consistency Changes: If the lubricant becomes thicker or thinner than normal, it may suggest contamination or breakdown of the lubricant itself.

Regular oil analysis can help detect these changes early and provide insights into the rate of wear.

5. Temperature Increases: A worn bearing may generate more heat during operation due to increased friction. Monitor for:

- Localized Hot Spots: Use infrared thermography to detect any unusual hot spots on the bearing or surrounding structure.

- Overall Temperature Increase: If the bearing is consistently running hotter than its normal operating temperature, this could indicate wear or lubrication issues.

It's important to establish a baseline for normal operation and regularly monitor these parameters to detect changes over time. Implementing a comprehensive condition monitoring program that includes regular inspections, vibration analysis, oil analysis, and performance monitoring can help detect wear early and inform maintenance decisions.

When any of these signs of wear are detected, it's crucial to take appropriate action. This may involve:

- Increasing the frequency of inspections and monitoring

- Adjusting lubrication practices

- Planning for bearing replacement during scheduled downtime

- Investigating the root cause of accelerated wear (e.g., misalignment, overloading, contamination)

Remember that the significance of these wear indicators can vary depending on the specific application and operating conditions of the four point contact ball slewing bearing. Always consult with the bearing manufacturer or a qualified engineer when interpreting these signs and making maintenance decisions.

By staying vigilant and responsive to these signs of wear, you can maximize the service life of your four point contact ball slewing bearings, ensure the reliability of your equipment, and optimize your maintenance practices.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. SKF Group. (2018). Slewing bearings.

2. Rothe Erde GmbH. (2021). Slewing Bearings Handbook. Dortmund, Germany.

3. Timken Company. (2020). Timken Engineering Manual: Bearings. Canton, OH, USA.

4. Schaeffler Technologies AG & Co. KG. (2019). Schaeffler Technical Pocket Guide. Herzogenaurach, Germany.

5. American Bearing Manufacturers Association. (2017). ABMA 9:2015 - Load Ratings and Fatigue Life for Ball Bearings. Washington, D.C., USA.

6. Hynix Corporation. (2022). Maintenance Guide for Industrial Slewing Bearings. Seoul, South Korea.

7. International Organization for Standardization. (2018). ISO 281:2007 - Rolling bearings - Dynamic load ratings and rating life. Geneva, Switzerland.

8. National Renewable Energy Laboratory. (2021). Wind Turbine Drivetrain Condition Monitoring. Golden, CO, USA.

9. Journal of Mechanical Engineering Science. (2019). "Wear Mechanisms in Slewing Bearings: A Comprehensive Review." Vol. 233, Issue 23.