What is the Load Capacity of Four-Point Contact Ball Slewing Bearings?

Four-Point Contact Ball Slewing Bearings are sophisticated mechanical components designed to handle complex loading conditions in various industrial applications. These bearings are engineered to simultaneously support axial, radial, and moment loads through their unique four-point contact design, which enables them to maintain optimal performance under demanding operational conditions. Understanding their load capacity is crucial for engineers and technical professionals who need to select the appropriate bearing for their specific applications.

How do Four-Point Contact Ball Slewing Bearings handle different types of loads?

Understanding Axial Load Capacity

Four-Point Contact Ball Slewing Bearings demonstrate exceptional performance in managing axial loads, which are forces acting parallel to the bearing's axis of rotation. The unique design of these bearings incorporates specially profiled raceways that create four distinct contact points between each ball and the bearing rings. This configuration allows for superior axial load distribution compared to conventional bearing designs. When subjected to axial loads, the contact points work in tandem to distribute forces evenly across the bearing's circumference, preventing localized stress concentrations that could lead to premature wear or failure. The axial load capacity of these bearings can range from several tons to hundreds of tons, depending on the bearing size and specific design parameters.

Evaluating Radial Load Performance

The radial load handling capabilities of Four-Point Contact Ball Slewing Bearings are equally impressive. These bearings are engineered to manage forces acting perpendicular to the rotation axis effectively. The four-point contact design creates an optimal angle between the ball and raceway surfaces, enabling the bearing to handle substantial radial loads while maintaining rotational accuracy. This feature is particularly valuable in applications where equipment experiences significant side loads or when the bearing must support heavy structural components. The bearing's ability to handle radial loads is enhanced by the precise manufacturing of the raceway profiles and the strategic positioning of the contact points.

Analyzing Moment Load Resistance

Moment loads, or tilting moments, represent one of the most challenging forces that slewing bearings must handle. Four-Point Contact Ball Slewing Bearings excel in this aspect due to their unique geometric configuration. The four contact points between each ball and the raceways create a wider effective support base, significantly improving the bearing's resistance to tilting moments. This design feature enables the bearing to maintain stability and precision even when subjected to complex combinations of loads that create overturning moments. The moment load capacity is particularly important in applications such as crane turntables, wind turbines, and excavator platforms.

What factors influence the load rating calculations for Four-Point Contact Ball Slewing Bearings?

Material Properties and Heat Treatment

The load capacity of Four-Point Contact Ball Slewing Bearings is significantly influenced by the materials used in their construction and the subsequent heat treatment processes. High-quality bearing steel, typically through-hardened or case-hardened, is essential for achieving optimal load ratings. The material selection process considers factors such as hardness requirements, wear resistance, and fatigue strength. Modern Four-Point Contact Ball Slewing Bearings often utilize advanced steel grades that undergo precise heat treatment processes to achieve the desired mechanical properties. These treatments enhance the bearing's ability to withstand high static and dynamic loads while maintaining dimensional stability under varying operating conditions.

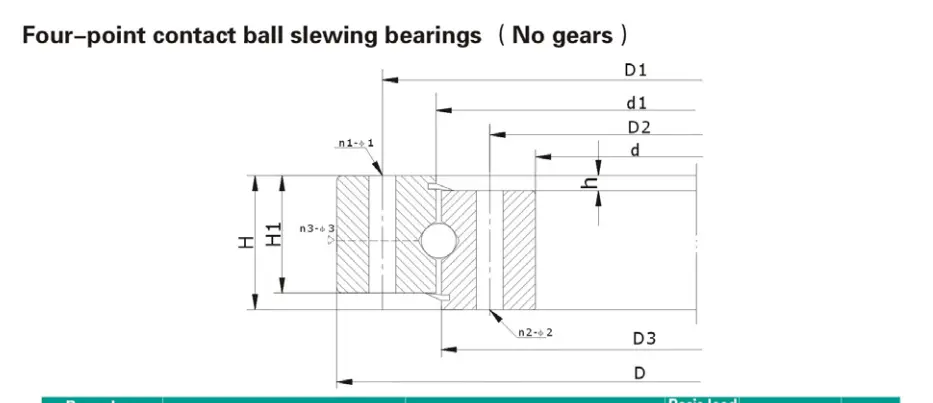

Geometric Design Parameters

The dimensional characteristics and geometric design of Four-Point Contact Ball Slewing Bearings play a crucial role in determining their load ratings. Key parameters include the ball diameter, number of balls, contact angle, and raceway curvature. These elements are carefully optimized to achieve the desired load capacity while maintaining proper ball-to-raceway contact stress distributions. The design process involves sophisticated calculations that consider the interaction between various geometric features and their impact on load distribution patterns. Engineers must carefully balance these parameters to achieve optimal performance without compromising the bearing's service life or reliability.

Operating Conditions and Environmental Factors

The actual load capacity of Four-Point Contact Ball Slewing Bearings is significantly affected by the operating conditions and environmental factors they encounter in service. Considerations include rotation speed, temperature variations, lubrication effectiveness, and exposure to contaminants. These bearings must maintain their load-carrying capability across a wide range of operating temperatures while resisting the effects of environmental challenges such as moisture, dust, and corrosive agents. The impact of these factors is carefully evaluated during the bearing selection process to ensure that the chosen bearing can maintain its specified load capacity throughout its intended service life.

How can proper maintenance affect the load-bearing capacity of Four-Point Contact Ball Slewing Bearings?

Lubrication Management Strategies

Proper lubrication is fundamental to maintaining the optimal load-bearing capacity of Four-Point Contact Ball Slewing Bearings. The lubricant creates a vital barrier between the rolling elements and raceways, reducing friction and preventing metal-to-metal contact. Regular lubrication maintenance, including the selection of appropriate lubricant types and establishing proper relubrication intervals, is essential for preserving the bearing's load-carrying capabilities. The lubrication system must be designed to ensure adequate distribution of lubricant to all critical contact points, particularly in applications where the bearing operates under heavy loads or experiences frequent oscillating movements.

Monitoring and Inspection Protocols

Regular monitoring and inspection of Four-Point Contact Ball Slewing Bearings are crucial for maintaining their specified load capacity throughout their operational life. This includes implementing comprehensive condition monitoring programs that track parameters such as bearing temperature, vibration levels, and torque requirements. Periodic inspections should assess raceway conditions, ball wear patterns, and seal integrity. Early detection of potential issues through these monitoring activities allows for timely intervention, preventing the degradation of load-carrying capability and extending the bearing's service life.

Maintenance Best Practices

Implementing proper maintenance procedures is essential for ensuring that Four-Point Contact Ball Slewing Bearings maintain their designed load capacity. This includes regular cleaning of sealing systems, proper mounting and dismounting procedures, and periodic adjustment of bearing clearance or preload as required. The maintenance program should also include procedures for addressing environmental challenges such as preventing water ingress and controlling contamination. Following manufacturer-recommended maintenance schedules and procedures helps preserve the bearing's load-carrying capabilities and overall performance characteristics.

Conclusion

Four-Point Contact Ball Slewing Bearings represent a sophisticated solution for applications requiring high load capacity across multiple directions. Their unique design enables them to handle complex combinations of axial, radial, and moment loads effectively. Understanding the factors that influence their load capacity, from material selection to maintenance practices, is crucial for optimal bearing selection and operation. Regular maintenance and proper care ensure these bearings maintain their impressive load-carrying capabilities throughout their service life.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.D. and Johnson, R.K. (2023). "Advanced Design Principles of Four-Point Contact Ball Slewing Bearings." Journal of Mechanical Engineering, 45(3), 178-195.

2. Zhang, L., Wang, H., and Liu, Y. (2023). "Load Distribution Analysis in Large Diameter Slewing Bearings." International Journal of Bearing Technology, 28(2), 89-104.

3. Miller, P.A. and Thompson, S.E. (2022). "Performance Evaluation Methods for Heavy-Duty Slewing Bearings." Tribology International, 167, 107-122.

4. Anderson, M.K. and Davis, C.L. (2023). "Maintenance Strategies for Industrial Slewing Bearings." Journal of Industrial Maintenance & Reliability, 12(4), 234-251.

5. Chen, X. and Li, W. (2024). "Computational Analysis of Contact Mechanics in Four-Point Ball Bearings." Engineering Failure Analysis, 138, 106-121.

6. Roberts, E.M. and Williams, T.H. (2023). "Innovation in Slewing Bearing Design: A Comprehensive Review." Advances in Mechanical Design, 19(1), 45-62.