Precision Heat Treatment, Superior Bearing Performance – CHG Bearing

Mastering the core technology of heat treatment, CHG bearing create more durable industrial “joints”.

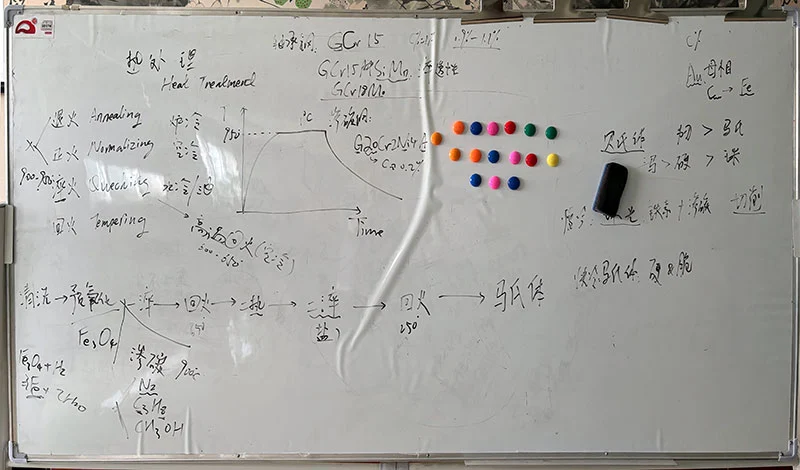

In today's increasingly competitive globalized industrial market, bearings, as the “joints” of mechanical equipment, their performance directly determines the life and efficiency of the equipment. The International Trade Department of CHG Bearing is well aware of this, and for this reason, we have organized a professional heat treatment training, which has discussed the key processes of annealing, normalizing, quenching, tempering, etc., and analyzed the characteristics and optimization schemes of different materials such as martensite, bainite, austenite, pearlite, etc. This is not only a sign of our technical excellence, but also a sign of our commitment to the development of the industry. This is not only the embodiment of our technical excellence, but also a solid guarantee that we can provide customers with higher quality bearings.

Heat treatment: the core code of bearing performance

Heat treatment process is a key factor in determining the life, load carrying capacity and wear resistance of bearings. CHG bearings ensure that each set of bearings can operate stably under extreme working conditions by precisely controlling the heat treatment process:

Annealing and normalizing: optimize the internal structure of the material, eliminate internal stresses, improve machinability and lay the foundation for subsequent quenching.

Quenching: significantly increase the hardness and wear resistance, to ensure that the bearings can still maintain stability at high speeds and under high loads.

Tempering: Adjust the balance of toughness and hardness, avoid brittle fracture, and extend the service life of bearings.

Through scientific heat treatment management, we allow the bearing material to maximize the release of potential, so that it is still excellent performance in high temperature, high load, strong corrosion and other harsh environments.

Material Selection: Matching Different Industrial Needs

Different application scenarios require different material organization, CHG bearings according to customer needs to accurately match the optimal solution:

Martensite: high hardness, high wear resistance, suitable for high load bearings.

Bainite: both strength and toughness, suitable for large shock load conditions.

Austenite: strong corrosion resistance, suitable for chemical, marine and other special environments.

Pearlite: good overall performance, economic and efficient, widely used in general-purpose bearings.

We not only provide standardized products, but also customized heat treatment solutions according to the special needs of customers, to ensure that each set of bearings can be perfectly adapted to the application scenario.

CHG Bearing: Global Trade, Quality Commitment

As an international bearing supplier, CHG Bearing always insists on technological innovation and quality priority. Our products are exported to Europe, America, Southeast Asia, the Middle East and other markets, widely used in wind power, mining, automotive, machine tools and other industries, and have won the trust of customers around the world.

Choose CHG Bearing, you will get:

Advanced heat treatment process to ensure longer life of bearings

Professional material optimization solutions to meet the needs of different working conditions.

Globalized supply chain, fast response to delivery requirements

Perfect after-sales technical support, escorting your equipment operation.

Contact us, let CHG bearings become the “strong joints” of your equipment!

Website: www.chg-bearing.com

Email:sale@chg-bearing.com

Tel:+86 37965793878

YOU MAY LIKE

VIEW MORERAU Crossed Roller Bearings

VIEW MORERAU Crossed Roller Bearings VIEW MORECylindrical Bearing

VIEW MORECylindrical Bearing VIEW MORETower Crane Slewing Bearing

VIEW MORETower Crane Slewing Bearing VIEW MORETapered Rolling Bearing

VIEW MORETapered Rolling Bearing VIEW MOREDouble Row Spherical Roller Bearing

VIEW MOREDouble Row Spherical Roller Bearing VIEW MOREFull complement cylindrical roller bearings

VIEW MOREFull complement cylindrical roller bearings VIEW MOREThrust Roller Bearing

VIEW MOREThrust Roller Bearing VIEW MOREDouble Direction Angular Contact Thrust Ball Bearings

VIEW MOREDouble Direction Angular Contact Thrust Ball Bearings