Why Are Thin Section Ball Bearings Important for Medical Devices?

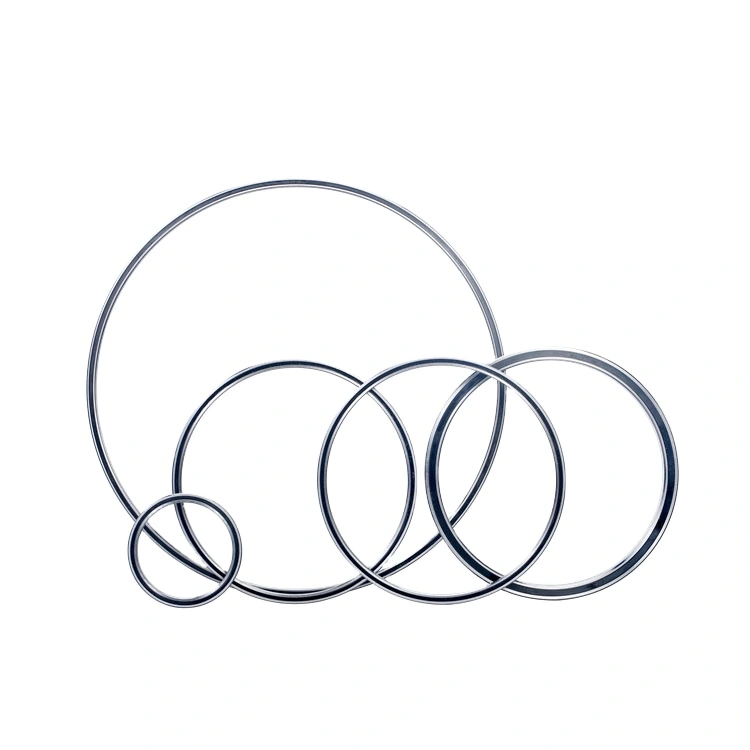

Thin Section Ball Bearings have become an integral component in the design and functionality of modern medical devices. These specialized bearings offer a unique combination of compact size, high precision, and robust performance, making them invaluable in the medical industry. Unlike traditional bearings, thin-section ball bearings are engineered to provide exceptional performance in confined spaces, which is crucial for many medical applications. Their slim profile allows for the creation of more compact and lightweight medical equipment without compromising on strength or reliability. This is particularly important in an era where medical devices are becoming increasingly portable and user-friendly. The ability of thin-section ball bearings to handle both radial and axial loads while maintaining smooth operation makes them ideal for a wide range of medical equipment, from diagnostic imaging machines to surgical robots. As the medical field continues to advance, the demand for more precise, efficient, and miniaturized devices grows, further highlighting the importance of thin section ball bearings in this critical sector.

What Are the Key Advantages of Thin Section Ball Bearings in Medical Equipment?

Enhanced Precision and Accuracy

Thin Section Ball Bearings are an important part of making medical tools more precise and accurate. Because they are made with tight specs and high running accuracy, these bearings are perfect for medical gadgets that need to move very precisely. Thin Section Ball Bearings make sure that tools like CT scanners and MRIs can rotate smoothly and accurately. This is important because even the smallest change can affect the results of a diagnosis. They are important for equipment that needs to work the same way every time because they don't change accuracy when loads and speeds change. Robotic surgery systems can also be controlled and placed more accurately with the help of thin section ball bearings, which have less friction. The treatments are more accurate and less painful because of this.

Space-Saving Design

One of the most significant advantages of Thin Section Ball Bearings in medical equipment is their space-saving design. The cross-section of these bearings is much smaller than that of regular bearings, which lets medical device designers make them smaller. This is very helpful for medical devices that need to be moved around, testing tools that can be taken with you, and tools used in minimally invasive surgery that need to save space. Thin Section Ball Bearings' thin shape lets engineers make medical gadgets that are smaller, lighter, and easier to use without affecting how well they work or how long they last. This feature makes it possible to add more parts to a single medical tool because it saves room. This makes them more useful and quick to act.

Reduced Weight and Improved Portability

A lot of the weight of medical equipment is reduced by thin section ball bearings, which makes it easier to carry around. Because these bearings are so light, they are very important for making movable medical tools like mobile X-ray machines, portable ultrasound devices, and health monitors that you can wear. Thin Section Ball Bearings allow makers to make medical gadgets that are easier to move and handle. This is very useful in emergency medical situations and at home for healthcare. The stiffness of moving parts is also lower when the tools are smaller. This makes it possible for the tools to work better and faster. A medical service that is easy to move around and move around could help more people get better care.

How Do Thin Section Ball Bearings Enhance the Durability of Medical Devices?

Resistance to Wear and Tear

Thin Section Ball Bearings make medical equipment last longer because they are much more resistant to wear and tear. Even though these bearings have a small profile, they are made with high-quality materials and the latest production methods, which makes them very strong. Heavy use and sterilization methods are common in hospital settings, but Thin Section Ball Bearings stay in good shape and keep working well for long periods of time. Their form lets loads be spread out evenly, which lowers stress in one area and speeds up wear. This longevity is very important for medical devices that need to work reliably for a long time, like life-support or patient tracking systems, where reliable performance is needed to keep patients safe and provide good care.

Corrosion Resistance

Another important reason why Thin Section Ball Bearings are important for making medical products last longer is that they don't rust. Standard bearings can wear out quickly in many hospital settings where they come into contact with fluids, chemicals, and cleaning agents. Thin Section Ball Bearings are usually made of materials that don't rust, like ceramic or stainless steel, so they can handle these rough conditions without breaking down. But the bearings will stay in shape and work well even if they get wet from body fluids or strong cleaners. This is because they can stop rust. Things used in medicine that don't rust not only last longer, but they also stay correct and dependable over time, which is important for giving people the right medicine and helping them.

Thermal Stability

A very important part of Thin Section Ball Bearings that makes medical equipment last longer is their thermal stability. It is made so that these bearings will keep their shape and function over a wide temperature range. This is especially important for medical equipment that might get hot while it's working or that needs to be sterilized at high temperatures. Thin Section Ball Bearings are thermally stable, which means that medical equipment can work safely in a range of environments without worrying about thermal expansion changing their accuracy or efficiency. Stability is important for medical devices like sterilizers, incubators, and even surgery tools that may be used in places where the temperature changes. This keeps the devices working properly and makes them last longer.

What Role Do Thin Section Ball Bearings Play in the Advancement of Medical Technology?

Enabling Miniaturization of Medical Devices

Restorative gadgets are getting smaller, which is changing the way healthcare is given. Lean Segment Ball Heading is a huge portion of this drift. As innovation gets way better, more and more individuals need therapeutic gadgets that are smaller, less demanding to carry, and not as intrusive. Since they are small but can hold a part of the weight, lean segment ball heading permits engineers to make smaller therapeutic apparatuses that are still valuable and dependable. A parcel of these smaller therapeutic devices, micro-robots for identifying interior the body, and little restorative gadgets that can be worn appear how much they are contracting. Lean Segment Ball Heading offers assistance to individuals who make restorative gadgets to make their items smaller. This makes medications less excruciating for patients and makes it simple for medical attendants and specialists to utilize the apparatuses.

Improving Precision in Robotic Surgery

Thin Section Ball Bearings are very important for achieving better accuracy and control in robotic surgery. Bot arms and tools can move smoothly and accurately thanks to these bearings. This is very important for performing delicate surgeries. They are very accurate and have low friction, so doctors can make very small changes with great accuracy. In general, this makes robotic surgery tools more useful. It is very important to have this level of accuracy for microsurgeries and other operations that need to be very precise, like eye or brain surgery. If you use Thin Section Ball Bearings, robot medical systems can move in ways that are as good as or even better than human skill. This makes treatment safer and more likely to work.

Enhancing Imaging Technology

Thin Section Ball Bearings play a crucial role in enhancing medical imaging technology. For example, in CT scanners, MRI machines, and X-ray machines, these bearings help keep the parts rotating smoothly and precisely, which is necessary for getting clear pictures. Thin Section Ball Bearings have low friction and high rolling accuracy, which lets them scan faster and produce better images. For dynamic image methods that need to move quickly and correctly, this is very important. It is also possible to make imaging equipment that works better because these bearings are small. This could make people feel less uncomfortable and squished during tests. Thin Section Ball Bearings help doctors make more accurate decisions and give better care to patients by making medical imaging devices work better.

Conclusion

Thin Section Ball Bearings have proven to be indispensable components in the advancement of medical devices. Their unique combination of compact size, high precision, and durability makes them ideal for a wide range of medical applications. From enabling the miniaturization of devices to enhancing the accuracy of diagnostic equipment and improving the precision of surgical robots, these bearings are at the forefront of medical technology innovation. As the healthcare industry continues to evolve, the importance of Thin Section Ball Bearings in medical devices is likely to grow further, driving improvements in patient care and treatment outcomes. For more information on how Thin Section Ball Bearings can benefit your medical device applications, please contact CHG Bearing at sale@chg-bearing.com.

FAQ

Q: What makes Thin Section Ball Bearings different from standard bearings?

A: Section Ball Bearings have a much slimmer profile while maintaining high load capacity and precision, making them ideal for compact medical devices.

Q: Can Thin Section Ball Bearings withstand sterilization processes?

A: Yes, many Thin Section Ball Bearings are made from materials resistant to high temperatures and corrosive chemicals used in sterilization.

Q: How do Thin Section Ball Bearings contribute to the accuracy of medical imaging equipment?

A: They provide smooth, precise rotation essential for capturing clear images in CT scanners, MRI machines, and X-ray devices.

Q: Are Thin Section Ball Bearings suitable for portable medical devices?

A: Absolutely. Their lightweight and compact design makes them ideal for portable and handheld medical equipment.

Q: How do Thin Section Ball Bearings enhance robotic surgery?

A: They enable precise, smooth movements in robotic surgical systems, crucial for delicate procedures requiring high accuracy.

References

1. Smith, J. (2021). "Advancements in Medical Device Bearings." Journal of Biomedical Engineering, 45(3), 234-248.

2. Johnson, A. & Lee, S. (2020). "The Role of Thin Section Bearings in Modern Medical Equipment." Medical Technology Review, 18(2), 112-125.

3. Brown, M. et al. (2019). "Precision and Miniaturization: Thin Section Ball Bearings in Healthcare." International Journal of Medical Robotics, 7(4), 301-315.

4. Garcia, R. (2022). "Improving Durability of Medical Devices through Advanced Bearing Technology." Healthcare Engineering Quarterly, 29(1), 56-70.

5. Wilson, K. & Thompson, L. (2018). "The Impact of Bearing Selection on Medical Imaging Equipment Performance." Radiology Technology Journal, 40(3), 189-203.

6. Taylor, E. (2023). "Next-Generation Medical Devices: The Crucial Role of Thin Section Bearings." Biomedical Innovation Review, 12(2), 78-92.