What is the Difference Between Radial and Thrust Ball Bearings?

Ball bearings are essential components in many mechanical systems, designed to reduce friction between moving parts and support loads. Two common types of ball bearings are radial and thrust ball bearings. While both serve the purpose of minimizing friction and facilitating smooth motion, they differ significantly in their design, load-bearing capabilities, and applications. This blog post will explore the key differences between radial and thrust ball bearings, focusing on the unique characteristics and uses of thrust ball bearings.

How do thrust ball bearings handle axial loads?

Thrust ball bearings are specifically designed to handle axial loads, which are forces acting parallel to the shaft's axis. This unique capability sets them apart from radial ball bearings, which are primarily designed to handle radial loads perpendicular to the shaft's axis.

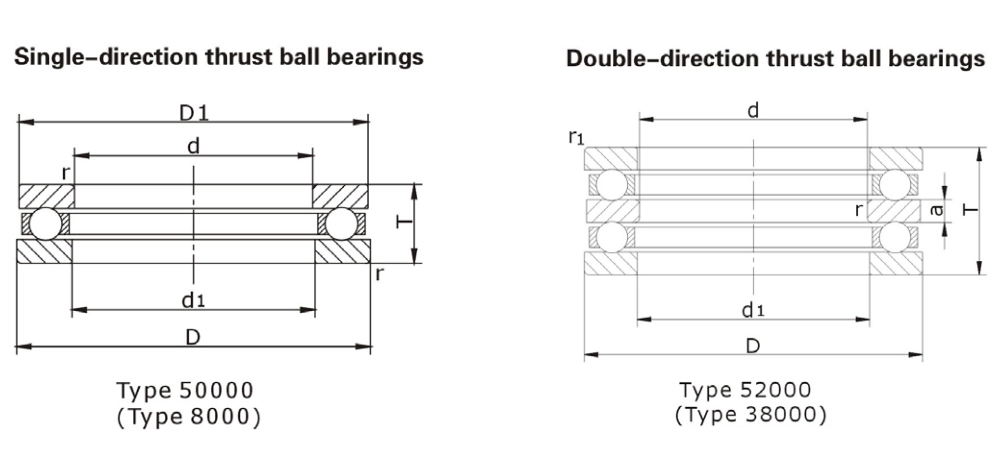

The structure of a thrust ball bearing consists of two washers, also known as races, with a series of balls sandwiched between them. This configuration allows the bearing to support significant axial loads in one direction. When an axial force is applied, the balls roll between the two races, distributing the load evenly and reducing friction.

The ability of thrust ball bearings to handle axial loads efficiently is due to several factors:

1. Large contact area: Thrust ball bearings typically have a larger contact area between the balls and the races compared to radial bearings. This increased surface area allows for better distribution of the axial load, reducing stress on individual components and improving overall load-bearing capacity.

2. Optimized ball size and quantity: The size and number of balls in a thrust bearing are carefully engineered to maximize load-carrying capacity while maintaining smooth operation. Larger balls can support heavier loads, while a higher number of balls can distribute the load more evenly.

3. Race design: The races in thrust ball bearings are designed with specific grooves or raceways that guide the balls and maintain proper alignment under axial loads. This design helps to minimize ball skidding and ensures efficient load distribution.

4. Cage or retainer: Many thrust ball bearings incorporate a cage or retainer that separates the balls and maintains their proper spacing. This component helps to prevent ball-to-ball contact, reducing friction and wear while ensuring smooth operation under axial loads.

5. Lubrication channels: Thrust ball bearings often feature lubrication channels or grooves that help distribute lubricant evenly across the bearing surfaces. Proper lubrication is crucial for maintaining low friction and preventing wear under high axial loads.

The unique design of thrust ball bearings allows them to excel in applications where high axial loads are present. They can support loads ranging from a few pounds to several tons, depending on their size and configuration. This makes them ideal for use in various industrial and automotive applications where axial forces are prevalent.

It's important to note that while thrust ball bearings are excellent at handling axial loads, they have limited capacity for radial loads. In applications where both axial and radial loads are present, other bearing types such as angular contact ball bearings or tapered roller bearings may be more suitable.

What are the common applications of thrust ball bearings?

Thrust ball bearings find widespread use across various industries due to their unique ability to handle axial loads efficiently. Their versatility and reliability make them indispensable in many mechanical systems. Let's explore some of the most common applications of thrust ball bearings:

1. Automotive Industry:

- Clutch systems: Thrust bearings are used in clutch release mechanisms to facilitate smooth engagement and disengagement of the clutch.

- Steering columns: They support the axial loads in steering columns, allowing for smooth rotation and precise steering control.

- Transmission systems: Thrust bearings are employed in gearboxes to handle the axial forces generated during gear shifting and power transmission.

2. Industrial Machinery:

- Pumps and compressors: Thrust bearings support the axial loads generated by impellers in centrifugal pumps and compressors, ensuring efficient operation and prolonging equipment life.

- Conveyor systems: They are used in the drive mechanisms of conveyor belts to handle the axial forces created by the movement of materials.

- Machine tools: Thrust bearings are crucial in the spindles of lathes, milling machines, and other precision tools to maintain accuracy under axial loads.

3. Marine Applications:

- Propeller shafts: Large thrust bearings support the enormous axial forces generated by ship propellers, allowing for efficient propulsion.

- Rudder systems: They are used in steering gear mechanisms to handle the axial loads created when maneuvering ships.

4. Aerospace:

- Helicopter rotors: Thrust bearings support the main rotor assemblies, handling the significant axial loads generated during flight.

- Turbine engines: They are used in various components of aircraft engines to manage axial loads and ensure smooth operation.

5. Construction Equipment:

- Excavators and cranes: Thrust bearings are employed in the slewing mechanisms of these machines, allowing for smooth rotation of the upper structure.

- Drilling equipment: They support the axial loads in drilling rigs, both for construction and oil and gas exploration.

The wide range of applications for thrust ball bearings demonstrates their importance in modern mechanical systems. Their ability to handle high axial loads while maintaining low friction makes them ideal for use in both high-speed and slow-speed applications, as well as in situations where intermittent or continuous axial loading occurs.

How do thrust ball bearings compare to other types of bearings in terms of efficiency?

When evaluating the efficiency of thrust ball bearings compared to other bearing types, it's essential to consider various factors such as load capacity, friction, speed capabilities, and overall performance in specific applications. Let's explore how thrust ball bearings stack up against other common bearing types in terms of efficiency:

1. Comparison with Radial Ball Bearings:

Thrust ball bearings are generally more efficient than radial ball bearings when it comes to handling axial loads. While radial bearings excel at managing radial forces, they are less effective at dealing with axial loads. Thrust bearings, with their specialized design, can handle much higher axial loads with lower friction, making them more efficient in applications where axial forces predominate.

However, it's important to note that thrust ball bearings are less efficient than radial bearings when it comes to radial loads. In applications where both radial and axial loads are present, a combination of both bearing types or the use of angular contact ball bearings might be more efficient.

2. Comparison with Roller Bearings:

When compared to roller bearings, such as cylindrical or tapered roller bearings, thrust ball bearings often exhibit lower friction, especially at higher speeds. This is due to the point contact between the balls and races, as opposed to the line contact in roller bearings. Lower friction translates to less heat generation and potentially higher efficiency in high-speed applications.

However, roller bearings generally have a higher load capacity than thrust ball bearings of similar size. In applications where very high axial loads are present, thrust roller bearings might be more efficient due to their ability to handle heavier loads without deformation.

3. Comparison with Plain Bearings:

Thrust ball bearings are generally more efficient than plain bearings (also known as bushings or sleeve bearings) in terms of friction reduction. Plain bearings rely on a thin film of lubricant to separate the moving surfaces, which can result in higher friction, especially at startup or low speeds. Thrust ball bearings, with their rolling elements, have inherently lower friction and can operate efficiently across a wider range of speeds.

However, plain bearings can be more cost-effective and may be preferred in certain low-speed, high-load applications or where simplicity and compactness are priorities.

4. Speed Considerations:

Thrust ball bearings are generally more efficient at higher speeds compared to many other bearing types. The rolling action of the balls allows for smooth operation with relatively low friction even at high rotational speeds. This makes them particularly efficient in applications such as high-speed pumps, turbines, and machine tool spindles.

However, at extremely high speeds, the centrifugal forces acting on the balls can reduce the bearing's efficiency and load-carrying capacity. In such cases, specialized high-speed thrust bearings or other bearing types might be more suitable.

5. Lubrication Efficiency:

Thrust ball bearings typically require less lubrication compared to some other bearing types, such as plain bearings or certain roller bearings. The rolling action of the balls helps distribute lubricant more effectively, reducing the need for continuous lubrication in many applications. This can lead to improved overall system efficiency and reduced maintenance requirements.

6. Size and Weight Efficiency:

For a given load capacity, thrust ball bearings often offer a more compact and lightweight solution compared to some other bearing types. This can be particularly advantageous in applications where space and weight are critical factors, such as in aerospace or automotive designs. The efficiency gained from reduced weight and size can translate to overall system performance improvements.

7. Misalignment Tolerance:

One area where thrust ball bearings may be less efficient is in their ability to handle misalignment. Compared to self-aligning bearings or spherical roller thrust bearings, standard thrust ball bearings have limited tolerance for angular misalignment. In applications where shaft deflection or misalignment is a concern, other bearing types might provide more efficient and reliable operation.

In conclusion, thrust ball bearings offer high efficiency in handling axial loads, particularly in high-speed applications with low to moderate loads. Their low friction characteristics, compact design, and ability to operate with minimal lubrication make them an efficient choice for many applications. However, the most efficient bearing choice always depends on the specific requirements of the application, including load type and magnitude, speed, space constraints, and environmental factors. Engineers must carefully consider these factors to select the most efficient bearing type for each unique application.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. SKF Group. (2021). Thrust ball bearings. SKF.com.

2. Schaeffler Technologies AG & Co. KG. (2021). Axial deep groove ball bearings.

3. NSK Ltd. (2021). Thrust Ball Bearings. NSK.com.

4. Timken Company. (2021). Thrust Ball Bearings. Timken.com.

5. NTN Corporation. (2021). Thrust Ball Bearings. NTN Global.

6. American Bearing Manufacturers Association. (2021). Ball Bearings. ABMA.com.

7. Khonsari, M. M., & Booser, E. R. (2017). Applied Tribology: Bearing Design and Lubrication. John Wiley & Sons.

8. Harris, T. A., & Kotzalas, M. N. (2006). Essential Concepts of Bearing Technology. CRC Press.

9. Hamrock, B. J., Schmid, S. R., & Jacobson, B. O. (2004). Fundamentals of Machine Elements. McGraw-Hill Higher Education.

10. ISO 104:2002. (2002). Rolling bearings — Thrust bearings, geometric product specifications (GPS) and tolerance values. International Organization for Standardization.