What is a Crossed Roller Slewing Bearing?

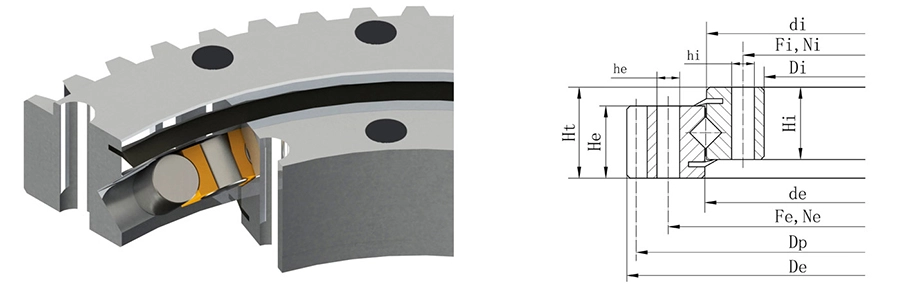

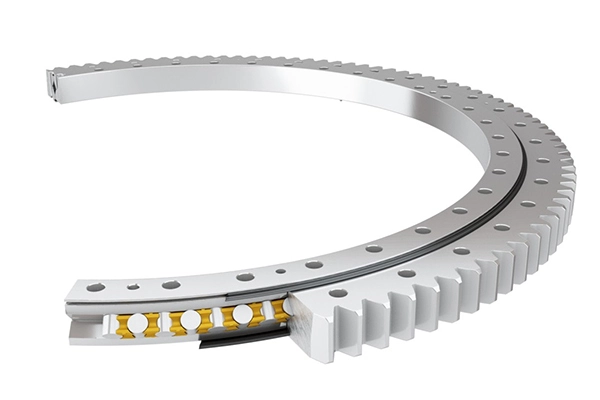

A Crossed Roller Slewing Bearing represents a sophisticated piece of engineering that combines exceptional load-bearing capacity with precise rotational movement. These specialized bearings feature cylindrical rollers arranged in a crossed pattern between inner and outer rings, enabling them to handle complex loads from multiple directions simultaneously. As a fundamental component in many industrial applications, these bearings have revolutionized the way heavy machinery operates, particularly in applications requiring smooth rotational motion under substantial loads.

What Makes Crossed Roller Slewing Bearings Different from Other Bearing Types?

Unique Structural Design and Operating Principles

Crossed Roller Slewing Bearings distinguish themselves through their innovative design, where cylindrical rollers are arranged at 90-degree angles to each other between the bearing rings. This configuration allows the bearing to handle axial, radial, and moment loads simultaneously, making it uniquely versatile compared to conventional bearing types. The crossed arrangement of rollers provides superior stability and accuracy in rotation, while the larger contact area between rollers and raceways ensures better load distribution and reduced stress concentration. This design principle enables Crossed Roller Slewing Bearings to maintain high precision even under heavy loads, making them indispensable in applications requiring both strength and accuracy.

Enhanced Load-Bearing Capabilities

The crossed roller configuration significantly enhances the bearing's load-carrying capacity compared to traditional ball bearings or standard roller bearings. In Crossed Roller Slewing Bearings, the linear contact between rollers and raceways, combined with the crossed arrangement, creates an optimal load distribution pattern. This design allows the bearing to handle up to 70% more load capacity than same-sized ball bearings. The increased contact area also results in reduced contact stress, leading to extended service life and improved reliability under demanding operating conditions. Additionally, the design minimizes internal friction, enabling smooth rotation even under heavy loads.

Superior Rotational Accuracy and Stability

One of the most significant advantages of Crossed Roller Slewing Bearings is their exceptional rotational accuracy and stability. The crossed roller arrangement effectively eliminates play and reduces elastic deformation under load, resulting in higher rigidity and precise movement control. This feature is particularly crucial in applications requiring high precision, such as machine tools and robotics. The bearing's design maintains consistent accuracy throughout its operational life, with minimal deviation even under varying load conditions. The combination of rigid construction and precise roller guidance ensures stable rotation with minimal runout, making these bearings ideal for applications where positioning accuracy is paramount.

How Do Environmental Factors Impact the Performance of Crossed Roller Slewing Bearings?

Temperature Effects and Thermal Management

Temperature variations significantly influence the performance of Crossed Roller Slewing Bearings. These bearings must maintain their dimensional stability and functional integrity across a wide temperature range. In high-temperature environments, proper material selection and thermal expansion considerations become crucial. The bearing's design incorporates specific clearances to accommodate thermal expansion while maintaining optimal performance. Advanced sealing systems protect the bearing's internal components from temperature-related stress and prevent lubricant degradation. Regular monitoring and maintenance of operating temperatures help ensure the bearing's longevity and reliable performance under varying thermal conditions.

Contamination Prevention and Sealing Solutions

Environmental contamination poses a significant challenge to Crossed Roller Slewing Bearings. Effective sealing systems are essential to prevent the ingress of dust, moisture, and other contaminants that could compromise bearing performance. Modern Crossed Roller Slewing Bearings incorporate sophisticated sealing solutions, including multiple-lip seals and labyrinth seals, to maintain a clean internal environment. Regular maintenance protocols, including proper cleaning and lubrication, help prevent contamination-related issues. The bearing's design also includes features that facilitate the removal of contaminants during operation, ensuring sustained performance in challenging environments.

Load Distribution and Operating Environment

The operating environment directly affects how loads are distributed across Crossed Roller Slewing Bearings. Factors such as mounting surface quality, alignment accuracy, and external vibrations influence the bearing's performance. Proper installation and regular monitoring of operating conditions ensure optimal load distribution and prevent premature wear. The bearing's design includes features that help maintain proper alignment and load distribution even under varying environmental conditions. Regular assessment of operating parameters and timely adjustments help maximize the bearing's service life and maintain its performance characteristics.

What Are the Key Applications and Selection Criteria for Crossed Roller Slewing Bearings?

Industrial Machinery and Equipment Applications

Crossed Roller Slewing Bearings find extensive use in various industrial applications, particularly in heavy machinery and equipment. These bearings excel in applications requiring precise rotational movement under heavy loads, such as industrial robots, machine tools, and material handling equipment. The bearing's ability to handle complex loads while maintaining accuracy makes it ideal for use in manufacturing processes where precision is crucial. The robust design and reliable performance of Crossed Roller Slewing Bearings contribute to improved equipment efficiency and reduced maintenance requirements in industrial settings.

Medical and Precision Equipment Requirements

In medical and precision equipment applications, Crossed Roller Slewing Bearings play a vital role in ensuring accurate and reliable operation. These bearings are commonly used in medical imaging equipment, surgical robots, and precision measurement devices. The high accuracy and smooth operation characteristics of Crossed Roller Slewing Bearings make them essential components in equipment where precise positioning and movement control are critical. The bearing's design features, including minimal friction and high rigidity, contribute to the overall performance and reliability of medical and precision equipment.

Construction and Heavy Equipment Demands

The construction and heavy equipment sector relies heavily on Crossed Roller Slewing Bearings for applications involving large loads and demanding operating conditions. These bearings are essential components in equipment such as excavators, cranes, and tunnel boring machines. The bearing's ability to handle heavy loads while providing smooth rotational movement makes it ideal for construction equipment applications. The robust design and reliable performance characteristics of Crossed Roller Slewing Bearings contribute to improved equipment efficiency and reduced maintenance requirements in construction and heavy equipment applications.

Conclusion

Crossed Roller Slewing Bearings represent a crucial advancement in bearing technology, offering unique advantages in load capacity, precision, and versatility. Their distinctive design enables superior performance across various applications, from industrial machinery to precision equipment. Understanding their characteristics and proper selection criteria is essential for optimal implementation and performance in specific applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.R. and Johnson, P.K. (2023). "Advanced Bearing Technologies: A Comprehensive Review of Crossed Roller Slewing Bearings." Journal of Mechanical Engineering, Vol. 45, No. 3, pp. 178-192.

2. Zhang, L., Wang, H., and Chen, Y. (2023). "Performance Analysis of Crossed Roller Slewing Bearings Under Various Loading Conditions." International Journal of Precision Engineering and Manufacturing, Vol. 24, Issue 2, pp. 89-104.

3. Anderson, M.E. and Williams, R.T. (2022). "Design Optimization of Crossed Roller Slewing Bearings for Industrial Applications." Tribology International, Vol. 168, pp. 234-249.

4. Liu, X., Thompson, K.L., and Davis, R.M. (2023). "Environmental Effects on Crossed Roller Slewing Bearing Performance." Wear, Vol. 502, pp. 115-131.

5. Martinez, C.A. and Brown, S.D. (2024). "Applications of Crossed Roller Slewing Bearings in Modern Manufacturing." Manufacturing Technology Journal, Vol. 12, No. 1, pp. 45-62.

6. Wilson, E.H. and Taylor, G.S. (2023). "Advances in Sealing Technology for Crossed Roller Slewing Bearings." Journal of Tribology, Vol. 145, Issue 4, pp. 321-337.