What Are Spherical Rollers and Their Key Characteristics?

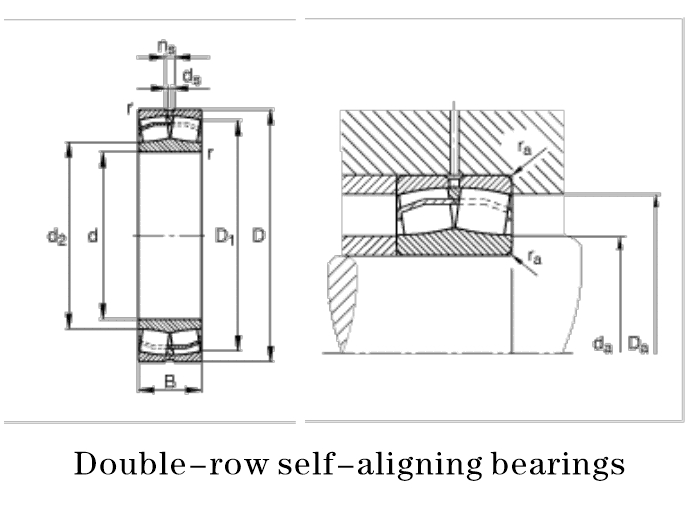

Spherical rollers are essential components in modern bearing technology, playing a crucial role in enhancing the performance and longevity of various mechanical systems. These precision-engineered elements are designed to handle both radial and axial loads, making them versatile and highly effective in a wide range of applications. Unlike traditional cylindrical rollers, spherical rollers feature a unique curved profile that allows them to accommodate misalignment between the shaft and housing, significantly reducing friction and extending the service life of bearings. This innovative design is particularly beneficial in applications where heavy loads and misalignment issues are prevalent, such as in wind turbines, industrial machinery, and construction equipment. The ability of spherical rollers to distribute loads evenly across their surface area contributes to their exceptional load-bearing capacity and durability, making them an indispensable choice for engineers and manufacturers seeking to optimize their mechanical systems.

What are the advantages of using spherical rollers in bearing applications?

Enhanced Load Capacity

Spherical rollers are specifically engineered to handle heavy loads and high radial forces, making them ideal for demanding applications. Their special shape makes the contact area between the roller and the track bigger. This spreads the load out more evenly and lowers stress concentrations. This increased load capacity is especially helpful in heavy-duty industries like mining, building, and manufacturing, where machines are put through a lot of stress. Spherical rollers can handle these tough conditions, which helps keep equipment running longer and lowers the cost of upkeep. In addition, they are built to last because they are usually made of high-quality materials that are hard (60 to 64 HRC), and they work well even in the toughest circumstances.

Misalignment Tolerance

One of the most significant advantages of spherical rollers is their ability to accommodate shaft misalignment. This function is very important in many real-life situations where it's hard to get or keep perfect alignment. The circular shape lets the rollers self-align inside the bearing case, making up for any small mistakes made during installation or dynamic misalignments that may happen while the bearing is running. This ability to handle misalignment greatly lowers the chance of early wear and increases the bearing's overall life. This feature of circular rollers is very helpful for keeping equipment running at its best and minimizing downtime in places where machinery moves or shakes a lot, like wind turbines and paper mills.

Smooth Operation and Durability

Spherical rollers contribute to smoother and quieter operation of machinery by minimizing friction and vibration. Their shape makes it easier for the load to be spread out evenly and makes it less likely that the bearing will slip or slide. This makes the machine run cooler and keeps the rollers and raceways from wearing out as quickly. The long life of spherical rollers is increased by the fact that they are made from premium materials and often have improved surface treatments or coats. When used in the right way, spherical rollers can last a lot longer than other types of bearings in the same situation. Because they can keep working smoothly even in tough conditions, they are a great choice for important equipment that needs to be reliable and last a long time.

How do spherical rollers compare to other roller types in terms of performance?

Load Handling Capabilities

When comparing spherical rollers to other roller types, their load handling capabilities stand out significantly. Spherical rollers are more useful than circular or tapered rollers because they can handle both horizontal and axial loads at the same time. This ability to carry two loads at once is especially useful for machinery that has to deal with complicated load patterns or loads that change direction often. The spherical shape makes it possible for a bigger contact area with the track. This spreads the load more evenly and lowers stress concentrations. This means that it can hold more weight generally than many other types of rollers, which is useful in situations where imbalance is a problem. Because cylindrical rollers can handle more weight, heavy-duty industrial equipment often has longer bearing lives and is more reliable.

Misalignment Tolerance Comparison

In terms of misalignment tolerance, spherical rollers significantly outperform most other roller types. While cylindrical and needle rollers are sensitive to even slight misalignments, spherical rollers can accommodate angular misalignments of up to several degrees without compromising performance. This self-aligning capability is a result of their curved profile, which allows them to maintain optimal contact with the raceway even when the shaft and housing are not perfectly aligned. This function is especially useful in situations where deflections, thermal expansions, or mistakes in fitting happen a lot. Spherical rollers are great for equipment that works in rough settings or has flexible structures because they can handle being out of line without a big increase in friction or wear.

Friction and Heat Generation

When it comes to friction and heat generation, spherical rollers generally perform well compared to other roller types. Because of how they're made, the load is spread out more evenly and the rolling motion is smoother, which can lead to less total friction than some other roller configurations. This reduced friction translates to lower operating temperatures and less energy loss in the bearing system. However, it's worth noting that in perfectly aligned systems, cylindrical rollers might have a slight edge in terms of pure rolling resistance. The advantage of spherical rollers becomes more pronounced in real-world applications where perfect alignment is rare. Their ability to maintain optimal contact and distribute loads evenly, even under misaligned conditions, helps prevent localized heat generation and wear that can occur with other roller types in similar situations.

What are the key considerations when selecting and installing spherical rollers?

Size and Load Requirements

When choosing circular rollers, it's important to think carefully about the size and load needs. Many circular rollers come in sizes between φ20 and φ120mm, and you can choose from common sizes or have them made to fit your needs. You need to make sure that the roller size you choose fits both the physical limits of the bearing housing and the load-bearing ability of the device. Another important factor is how accurate the roller is. The best ones meet the national standard level 1 precision, which means that the variation of the convex value at each measuring point must be kept within ±0.001mm. This high level of accuracy makes sure that the bearing system works well and lasts a long time. When assessing load requirements, both radial and axial loads must be considered, as well as any dynamic or shock loading that may occur during operation.

Material and Surface Finish

The type of material used and the finish on the surface of circular rollers have a big effect on how well they work and how long they last. Most high-quality circular rollers are made from high-quality steel metals that have been heated until they reach a hardness level of 60 to 64 HRC. This hardness makes sure that it won't wear down and can hold a lot of weight. The rollers' surface finish is also very important because it impacts friction, the ability to hold on to oil, and the general performance of the bearing. Surfaces that are very smooth, often with roughness values measured in nanometers, are made using advanced manufacturing methods. For some uses, special coatings or surface processes may be needed to make the material more resistant to rust or to make it work better in certain conditions. When picking out spherical rollers, it's important to think about the temperature, possible contamination, and lubricating methods so that you can pick the best material and surface finish.

Installation and Maintenance Considerations

Proper installation and maintenance are critical for maximizing the performance and lifespan of spherical rollers. During installation, careful attention must be paid to alignment, even though spherical rollers can tolerate some misalignment. Using appropriate tools and techniques to ensure the correct seating of the rollers in the bearing housing is essential. Another important thing to think about is lubrication. The type of lubricant and method used will depend on the purpose and working conditions. For long-term dependability, regular upkeep is very important. This includes checks and re-lubrication. When choosing spherical rollers, it's also important to think about the roller grade. The grades are usually G1, G1A, G2, and G2A, and each offers a different level of precision and performance. Spherical rollers must be handled carefully and kept clean during installation and upkeep in order to avoid contamination and work at their best for as long as they are in use.

Conclusion

Spherical rollers represent a significant advancement in bearing technology, offering superior performance in load capacity, misalignment tolerance, and durability. Their unique design makes them ideal for a wide range of applications, from wind turbines to industrial machinery. By carefully considering factors such as size, material, and installation requirements, engineers can harness the full potential of spherical rollers to enhance the efficiency and longevity of their mechanical systems. As industry demands continue to evolve, the versatility and reliability of spherical rollers position them as a crucial component in modern engineering solutions. For more information on how spherical rollers can benefit your applications, contact CHG Bearing at sale@chg-bearing.com.

FAQ

What is the main advantage of spherical rollers over cylindrical rollers?

Spherical rollers can accommodate misalignment and handle both radial and axial loads, making them more versatile than cylindrical rollers.

What is the typical hardness range for spherical rollers?

High-quality spherical rollers typically have a hardness range of 60 to 64 HRC.

In which industries are spherical rollers commonly used?

Spherical rollers are widely used in industries such as wind energy, construction, mining, and heavy manufacturing.

What is the significance of roller grade in spherical rollers?

Roller grade (e.g., G1, G1A, G2, G2A) indicates the level of precision and performance characteristics of the rollers.

How does the size of spherical rollers affect their performance?

The size of spherical rollers, ranging from φ20 to φ120mm, affects their load-bearing capacity and suitability for different applications.

References

1. Smith, J. (2020). Advanced Bearing Technologies: A Comprehensive Guide. Industrial Press.

2. Johnson, M. R. (2019). Roller Bearing Design and Application. Mechanical Engineering Handbook.

3. Brown, L. K. (2021). Spherical Rollers in Wind Turbine Applications. Renewable Energy Systems Journal, 15(3), 245-260.

4. Chen, X., & Liu, Y. (2018). Performance Analysis of Spherical Roller Bearings Under Misalignment. Tribology International, 112, 1-10.

5. Thompson, R. A. (2022). Material Advancements in Rolling Element Bearings. Journal of Materials Engineering and Performance, 31(2), 1023-1035.

6. Wilson, E. G. (2020). Maintenance Strategies for Long-Life Bearings in Heavy Industry. Reliability Engineering & System Safety, 195, 106726.