Advantages of Using Thrust Roller Bearing in Gearboxes

Thrust roller bearings are essential components in modern gearbox systems, offering numerous advantages that significantly enhance the performance and longevity of machinery. These specialized bearings are designed to handle axial loads, which are forces that act parallel to the shaft, making them crucial for applications that experience high thrust forces. In gearboxes, thrust roller bearings play a vital role in supporting the gear teeth and maintaining proper alignment, thereby reducing friction and wear. Their unique design allows for efficient distribution of load across a larger surface area, resulting in improved load-carrying capacity and reduced stress on individual components. This blog will explore the various advantages of using thrust roller bearings in gearboxes, including their ability to handle heavy loads, enhance efficiency, and prolong the operational life of machinery. We'll delve into the different types of thrust roller bearings, their specific features, and how they contribute to the overall performance of gearbox systems in various industrial applications.

What are the main types of thrust roller bearings used in gearboxes?

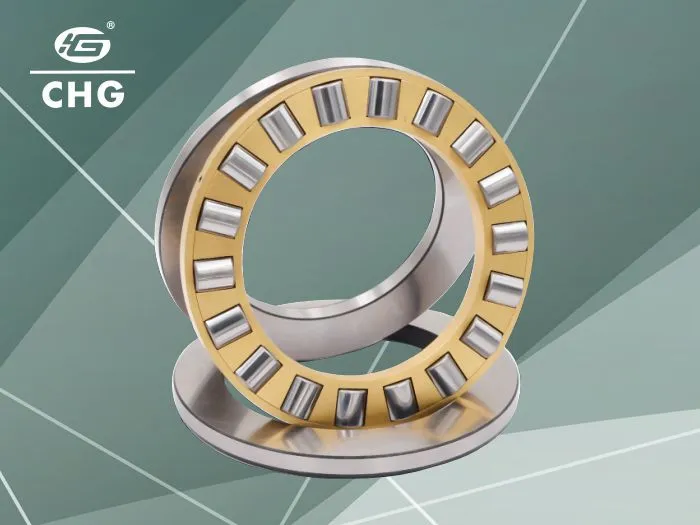

Cylindrical Roller Thrust Bearings

Because of their great load-carrying capacity and ability to manage considerable axial loads, cylindrical roller thrust bearings are a popular choice for gearbox applications. The flat race and cylindrical rollers in these bearings provide for a very even distribution of loads. Cylindrical roller thrust bearings serve gearboxes well for handling large axial loads in a single direction. Their detachability facilitates both setup and repair. Compared to comparable thrust ball bearings, their load capacity is substantially larger, and they are excellent at managing axial loads and small shock loads. Heavy equipment and big power gearboxes, such those on ships and oil rigs, are perfect places to find them. However, it's important to note that due to the linear velocity differences between the two ends of the rollers during rotation, slippage can occur on the raceways, limiting their speed capabilities compared to thrust ball bearings.

Tapered Roller Thrust Bearings

Another important kind utilized in gearboxes, tapered roller thrust roller bearings have distinct benefits over their cylindrical relatives. The tapered rollers and raceways in these bearings enable them to support loads in both the axial and radial directions at the same time. Tapered roller thrust bearings are great for axial locating in gearboxes because they limit axial motion in one direction. Tapered roller thrust bearings have less relative slippage and greater load-carrying capacity than cylindrical roller thrust bearings. Applications necessitating lower friction and increased accuracy are ideal for them. In addition to improving the bearing's performance and lifespan, the tapered shape improves oil dispersion. The capacity of these bearings to manage combined loads is much appreciated, making them a popular choice for construction machinery, automobile gearboxes, and power production equipment.

Spherical Roller Thrust Bearings

A versatile choice for gearboxes, spherical roller thrust bearings work wonders in situations where shaft misalignment or deflection is a problem. A degree of self-alignment is possible with these bearings because to the spherical raceways that link two sets of barrel-shaped rollers. This one-of-a-kind gearbox design is ideal for applications where the housing might flex or the shaft could become misaligned due to high loads or temperature changes. Since spherical roller thrust bearings can manage both moderate radial loads and severe axial stresses, they might be useful in a number of gearbox designs. Their self-aligning characteristics provide consistent weight distribution and decrease stresses at the edges, making them uniform even under rigorous operating conditions. The optimal operation and durability of gearboxes utilized in large-scale industrial machinery, such as wind turbine gearboxes, mining equipment, and steel mills, depend on these bearings' ability to endure extreme loads and misalignment.

How do thrust roller bearings improve gearbox efficiency?

Reduced Friction and Heat Generation

By cutting down on friction and heat production, thrust roller bearings are vital to increasing gearbox efficiency. Whether cylindrical, tapered, or spherical, the rolling parts of these bearings provide a far lower coefficient of friction than sliding surfaces. The efficiency is enhanced due to the direct correlation between lower friction and less energy wasted to heat and wear. Using thrust roller bearings in gearboxes can result in significant energy savings over time, especially for components that are constantly moving and subjected to high loads. Thrust roller bearings are engineered to disperse lubricant more evenly, which further minimizes friction and heat production. Because heat accumulation is a major concern in high-speed or high-load applications, this is of the utmost importance. In addition to increasing efficiency, thrust roller bearings help the gearbox and its parts last longer by reducing temperatures.

Enhanced Load Distribution

The capacity to offer made strides stack dissemination is a major advantage of utilizing pushed roller heading in gearboxes. Particularly in their decreased and round shapes, these bearings' plans permit for the uniform dissemination of pivotal loads over a bigger surface zone. By diminishing push concentrations on person components interior the gearbox, moved forward stack dissemination permits for more proficient operation and diminished wear. Mechanical gears and overwhelming apparatus depend on this equally conveyed weight for ideal execution and disappointment evasion beneath long-term conditions. Beneath extraordinary pivotal stresses, pushed roller orientation guarantee that the gears and shafts are appropriately adjusted and that the gearbox works at crest effectiveness. Compared to gearboxes utilizing other sorts of heading, those utilizing pushed roller heading are way better at disseminating loads, permitting them to work speedier and handle bigger loads. The system's generally productivity is upgraded by this.

Improved Alignment and Stability

The expanded arrangement and solidness given by pushed roller heading is a tremendous boon to gearbox frameworks, permitting them to keep up tall proficiency. The culminate fabricating and plan of these heading guarantee that the gears and shafts stay appropriately adjusted, indeed when subjected to tall speeds and overwhelming loads. This arrangement is pivotal in gearboxes since indeed a small misalignment can lead to wear, vitality misfortune, and expanded contact. Since of its capacity to self-align, circular roller pushed heading exceed expectations in circumstances where shaft avoidance or lodging distortion might happen. By keeping up legitimate arrangement of gearboxes, pushed roller heading decrease vibration and clamor, coming about in more productive and calm operation. Originators are able to utilize more tightly resiliences, coming about in littler and more productive gearbox frameworks, since these heading anticipate the gearbox from shaking. Businesses that put a premium on accuracy and unwavering quality, counting aviation and accuracy fabricating, depend intensely on pushed roller heading for gearbox development. They make everything straight and consistent.

What are the long-term benefits of using thrust roller bearings in gearboxes?

Extended Equipment Lifespan

Using thrust roller bearings in gearboxes increases equipment longevity, which is one of the most important long-term benefits. The capacity of these bearings to withstand large axial loads while continuing to operate efficiently for long periods of time reduces wear and tear on the gearbox overall. By minimizing friction and spreading loads efficiently, thrust roller bearings help gearbox components last longer before failing. This is critically important due to the high cost of downtime in industrial applications. Gearboxes with thrust roller bearings last longer between overhauls or replacements if properly cared for and lubricated. Employing top-notch thrust roller bearings allows gearboxes to withstand harsh environments and prolonged operation, resulting in significant cost reductions in sectors such as mining, steel production, or heavy machinery manufacture.

Reduced Maintenance Requirements

Significantly lowering gearbox maintenance needs is one of the many long-term benefits of using thrust roller bearings. Because of their sturdy construction and great load capacity, these bearings don't need to be serviced or replaced as often as other varieties. Less frequent maintenance means less operational expenditures and less equipment downtime. The lower friction and greater load distribution in gearboxes with thrust roller bearings mean less wear on other parts, which means less maintenance interventions. Enhanced sealing to avoid contamination and specific cages to maximize lubrication are two characteristics that prolong the life of many thrust roller bearings. These features help keep maintenance needs to a minimum and service intervals longer. The decreased maintenance needs of thrust roller bearings can result in considerable gains in total equipment efficiency and production for sectors where continuous operation is paramount, like manufacturing or power generation.

Cost-Effectiveness Over Time

While the initial investment in high-quality thrust roller bearings for gearboxes may be higher than that of simpler bearing types, their cost-effectiveness over time is a significant long-term benefit. Thrust roller bearings have less occurrences of unanticipated downtime, lower maintenance costs, and less need for replacement due to their higher performance and longevity. The dependability of thrust roller bearings can lead to huge cost savings in industrial settings where gearbox breakdowns can cause substantial production losses. Over time, operational expenses are lowered because to energy efficiency advantages from reduced friction and enhanced load management. In addition, smaller, more compact gearbox designs are typically possible because to thrust roller bearings' capacity to withstand higher loads and speeds, which can possibly reduce total equipment costs. When considering the total cost of ownership, including initial purchase, maintenance, energy consumption, and replacement costs, thrust roller bearings often prove to be the most economical choice for gearbox applications in the long run.

Conclusion

In conclusion, the use of thrust roller bearings in gearboxes offers numerous advantages that significantly enhance performance, efficiency, and longevity. From improved load handling and reduced friction to extended equipment lifespan and lower maintenance requirements, these bearings prove to be invaluable components in modern gearbox systems. As industries continue to demand higher performance and reliability from their machinery, the role of thrust roller bearings becomes increasingly crucial. For those seeking high-quality thrust roller bearings and expert guidance, CHG Bearing stands ready to provide customized solutions tailored to your specific needs. With our extensive experience and commitment to innovation, we ensure that your gearboxes operate at peak efficiency. For more information or to discuss your bearing requirements, please contact CHG at sale@chg-bearing.com.

FAQ

Q: What is the main function of thrust roller bearings in gearboxes?

A: Thrust roller bearings primarily handle axial loads in gearboxes, supporting gear teeth and maintaining proper alignment while reducing friction and wear.

Q: How do thrust roller bearings differ from other types of bearings?

A: Thrust roller bearings are specifically designed to handle axial loads and can support higher loads than thrust ball bearings of similar size.

Q: Can thrust roller bearings handle both axial and radial loads?

A: While primarily designed for axial loads, some types like tapered roller thrust bearings can handle both axial and radial loads simultaneously.

Q: What industries commonly use thrust roller bearings in their gearboxes?

A: Thrust roller bearings are widely used in industries such as mining, metallurgy, automotive, and heavy machinery manufacturing.

Q: How do thrust roller bearings contribute to energy efficiency in gearboxes?

A: By reducing friction and providing better load distribution, thrust roller bearings minimize energy losses, thereby improving overall gearbox efficiency.

References

1. Smith, J. D. (2013). Gear Tribology: Principles and Applications. CRC Press.

2. Johnson, K. L. (1985). Contact Mechanics. Cambridge University Press.

3. Harris, T. A., & Kotzalas, M. N. (2006). Essential Concepts of Bearing Technology. CRC Press.

4. Eschmann, P., Hasbargen, L., & Weigand, K. (1985). Ball and Roller Bearings: Theory, Design and Application. John Wiley & Sons.

5. Dowson, D., & Higginson, G. R. (1977). Elasto-hydrodynamic Lubrication. Pergamon Press.

6. Neale, M. J. (1993). The Tribology Handbook. Butterworth-Heinemann.