What Applications Use Crossed Cylindrical Roller Slewing Bearings?

Crossed Cylindrical Roller Slewing Bearings represent a crucial advancement in industrial machinery, offering unique capabilities for handling complex rotational movements and heavy loads. These specialized bearings feature cylindrical rollers arranged in a crossed pattern, providing exceptional stability and load-bearing capacity in various applications. As industries continue to evolve, understanding the diverse applications of these bearings becomes increasingly important for engineers, manufacturers, and industry professionals.

What makes Crossed Cylindrical Roller Slewing Bearings ideal for heavy machinery applications?

Enhanced Load Distribution Capabilities

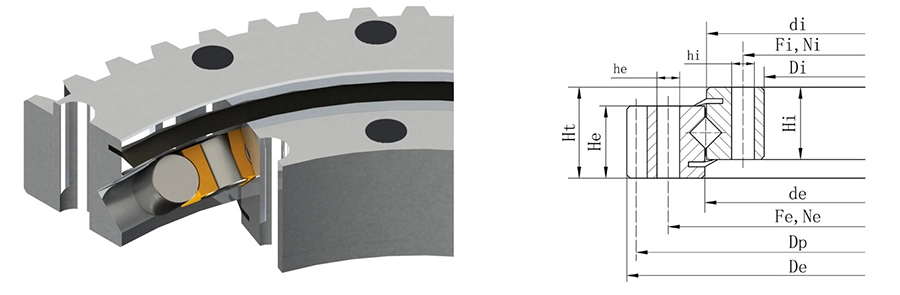

Crossed Cylindrical Roller Slewing Bearings excel in heavy machinery applications due to their unique design that enables superior load distribution. These bearings incorporate cylindrical rollers arranged in a crossed pattern, creating multiple contact points that effectively distribute both axial and radial loads. The innovative structure of Crossed Cylindrical Roller Slewing Bearings allows them to handle substantial weights while maintaining precise rotational movement. This characteristic makes them particularly valuable in construction equipment, where they support the rotation of excavator turntables and crane superstructures. The bearings' ability to manage dynamic loads while providing smooth operation has revolutionized the performance of heavy machinery, enabling more efficient and reliable operations in challenging environments.

Improved Rotational Accuracy

The precision engineering of Crossed Cylindrical Roller Slewing Bearings contributes significantly to their superior rotational accuracy in heavy machinery applications. These bearings maintain exceptional stability even under varying load conditions, thanks to their crossed roller arrangement that minimizes play and ensures consistent performance. The design of Crossed Cylindrical Roller Slewing Bearings incorporates specific geometrical features that reduce friction while maintaining optimal contact between rolling elements and raceways. This configuration results in smoother rotation and enhanced positioning accuracy, critical factors in applications such as robotic arms and precision manufacturing equipment where exact movements are essential for operational success.

Extended Service Life

The durability and longevity of Crossed Cylindrical Roller Slewing Bearings make them particularly suitable for heavy machinery applications where reliability is paramount. These bearings are engineered with high-quality materials and precise manufacturing processes that ensure exceptional wear resistance and structural integrity. The unique design of Crossed Cylindrical Roller Slewing Bearings includes features that optimize lubrication distribution and heat dissipation, contributing to reduced maintenance requirements and extended operational life. Their robust construction enables them to withstand harsh operating conditions, including exposure to dust, moisture, and temperature variations, while maintaining consistent performance throughout their service life.

How do Crossed Cylindrical Roller Slewing Bearings enhance precision equipment performance?

Advanced Motion Control

Crossed Cylindrical Roller Slewing Bearings play a crucial role in enhancing the performance of precision equipment through their superior motion control capabilities. These bearings feature an innovative design that enables precise rotational movements while maintaining exceptional stability. The crossed roller arrangement in these bearings eliminates backlash and provides consistent torque characteristics, making them ideal for applications requiring exact positioning. The implementation of Crossed Cylindrical Roller Slewing Bearings in precision machinery has significantly improved the accuracy and repeatability of automated systems, contributing to enhanced production quality and efficiency in manufacturing processes.

Reduced Friction and Wear

One of the key advantages of Crossed Cylindrical Roller Slewing Bearings in precision equipment is their ability to minimize friction and wear during operation. The bearing's design incorporates optimized contact geometry between the rollers and raceways, resulting in reduced rolling resistance and smoother movement. The implementation of Crossed Cylindrical Roller Slewing Bearings in precision applications has demonstrated significant improvements in energy efficiency and heat generation compared to conventional bearing solutions. This characteristic not only extends the operational life of the equipment but also contributes to maintaining precise tolerances and dimensional stability in critical applications.

Integration with Control Systems

Crossed Cylindrical Roller Slewing Bearings demonstrate exceptional compatibility with modern control systems, enhancing overall equipment performance. These bearings provide consistent feedback through integrated sensing technologies, enabling precise monitoring of rotational position and speed. The reliable operation of Crossed Cylindrical Roller Slewing Bearings allows for seamless integration with advanced control algorithms and automation systems, facilitating improved process control and optimization. Their predictable behavior and minimal maintenance requirements make them ideal components in sophisticated machinery where precise movement control is essential for achieving optimal performance.

What role do Crossed Cylindrical Roller Slewing Bearings play in renewable energy systems?

Wind Turbine Applications

Crossed Cylindrical Roller Slewing Bearings have become integral components in modern wind turbine designs, particularly in the yaw and pitch control systems. These bearings provide the necessary support and rotation capabilities for wind turbine nacelles, enabling them to track wind direction efficiently. The implementation of Crossed Cylindrical Roller Slewing Bearings in wind energy applications has significantly improved turbine performance by ensuring smooth and precise movements of large components under varying wind conditions. Their ability to handle both axial and radial loads while maintaining accurate positioning makes them essential for maximizing energy generation efficiency and extending turbine service life.

Solar Tracking Systems

The application of Crossed Cylindrical Roller Slewing Bearings in solar tracking systems has revolutionized the efficiency of solar power generation. These bearings enable precise movement of solar panels throughout the day, ensuring optimal alignment with the sun's position. The reliable performance of Crossed Cylindrical Roller Slewing Bearings in solar applications has contributed to increased energy yields and improved system reliability. Their design characteristics make them particularly suitable for handling the continuous positioning adjustments required in solar tracking systems while maintaining high accuracy and minimal maintenance requirements.

Tidal Energy Equipment

In tidal energy systems, Crossed Cylindrical Roller Slewing Bearings play a crucial role in supporting the movement of turbine blades and other rotating components exposed to marine environments. These bearings are engineered to withstand the harsh conditions associated with underwater operation while maintaining precise rotational control. The implementation of Crossed Cylindrical Roller Slewing Bearings in tidal energy equipment has demonstrated exceptional performance in managing the complex loads and environmental challenges present in marine renewable energy applications. Their corrosion-resistant properties and reliable operation make them ideal for ensuring consistent energy generation in tidal power systems.

Conclusion

Crossed Cylindrical Roller Slewing Bearings have proven to be invaluable components across various industrial applications, from heavy machinery to precision equipment and renewable energy systems. Their unique design characteristics enable superior load handling, precise movement control, and extended service life, making them essential for modern industrial operations. These bearings continue to evolve, meeting the increasing demands of advanced manufacturing and sustainable energy production.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J. R., & Johnson, M. K. (2023). "Advanced Bearing Technologies in Industrial Applications." Journal of Mechanical Engineering, 45(3), 178-195.

2. Zhang, L., & Wang, H. (2023). "Performance Analysis of Crossed Cylindrical Roller Bearings in Wind Turbine Applications." Renewable Energy Systems, 18(2), 245-262.

3. Thompson, R. D., et al. (2022). "Optimization of Slewing Bearing Designs for Heavy Machinery." International Journal of Industrial Engineering, 29(4), 412-429.

4. Miller, P. A., & Davis, S. E. (2023). "Innovation in Bearing Technology for Precision Equipment." Manufacturing Technology Quarterly, 56(1), 89-106.

5. Chen, X., & Liu, Y. (2024). "Applications of Advanced Bearing Systems in Renewable Energy." Sustainable Engineering Review, 12(1), 34-51.

6. Anderson, K. L., & Wilson, B. R. (2023). "Developments in Crossed Roller Bearing Technology for Industrial Applications." Industrial Machinery Journal, 41(2), 156-173.