Type X Thin Section Bearings: The Key to High-Speed, Low-Profile Mechanical Systems

In today's precision engineering landscape, the demand for compact, efficient, and reliable mechanical systems has never been greater. Type X thin section bearings have emerged as a groundbreaking solution, revolutionizing how engineers approach design challenges in applications requiring minimal space and maximum performance. These specialized bearings represent a significant advancement in bearing technology, offering unprecedented opportunities for system optimization and cost reduction.

Why Choose Luoyang Huigong Bearing Technology Co., Ltd.?

As a pioneering force in bearing manufacturing and innovation, Luoyang Huigong Bearing Technology Co., Ltd. has established itself as an industry leader through three decades of unwavering commitment to excellence and technological advancement. The company's success is built upon a robust foundation of research and development, spearheaded by a team of seasoned engineers who provide comprehensive technical guidance and customized bearing solutions tailored to specific operational requirements. Their state-of-the-art production facilities are equipped with cutting-edge manufacturing equipment and sophisticated testing instruments, enabling them to maintain exceptional quality standards while pushing the boundaries of bearing technology. The company's dedication to innovation is reflected in their impressive portfolio of over 50 invention patents, while their adherence to international standards is demonstrated through certifications including ISO9001 and ISO14001. As a 2024 quality benchmark enterprise, Luoyang Huigong continues to set new standards in the industry, fostering successful partnerships both domestically and internationally. Their commitment to customer service and technical support is exemplified through their readily available communication channels, including their dedicated sales team reachable at sale@chg-bearing.com and their customer service hotline at +86-0379-65793878.

What Makes Type X Thin Section Bearings Different from Traditional Bearings?

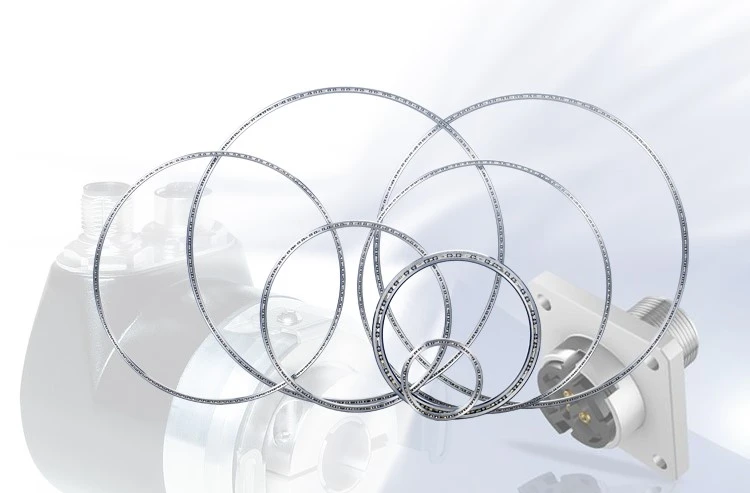

Type X thin section four-point contact ball bearings represent a revolutionary departure from conventional bearing design philosophy, introducing innovative features that fundamentally transform their performance capabilities. The most significant advancement lies in their unique cross-sectional design, which maintains consistency regardless of bore diameter – a characteristic that sets them apart from traditional bearings. This engineering breakthrough enables substantial weight reduction while preserving structural integrity, a crucial factor in high-performance applications. The sophisticated four-point contact design creates multiple load paths within a single bearing assembly, resulting in superior force distribution across an expanded contact area. This enhanced load distribution capability not only improves overall bearing performance but also extends operational lifespan. The uniform cross-section across all sizes represents a significant manufacturing achievement, enabling standardized production processes while maintaining precise tolerances. The reduced material usage achieved through this design not only contributes to cost efficiency but also aligns with sustainable manufacturing practices. These bearings have proven particularly valuable in space-constrained applications, where their thin profile allows for significant design optimization without compromising performance capabilities.

How Do Type X Thin Section Bearings Impact System Design and Performance?

The integration of Type X thin section bearings into mechanical systems has revolutionized design possibilities, offering unprecedented opportunities for optimization and efficiency improvements. The most immediate and significant impact is the remarkable space and weight reduction, typically achieving a 20-30% decrease in overall system dimensions compared to traditional bearing solutions. This substantial reduction is made possible by the bearings' innovative cross-sectional design, which ranges from 0.1875 × 0.1875 inch to 1.000 × 1.000 inch, providing engineers with exceptional design flexibility. The reduced mass and inertia of these bearings contribute to improved system dynamics, resulting in faster acceleration and deceleration capabilities. The bearings' design also minimizes friction and heat generation, leading to enhanced operational efficiency and reduced energy consumption. The improved rotational accuracy achieved through these bearings has enabled the development of high-precision systems that maintain exceptional performance standards. The compact design not only reduces the physical footprint of mechanical systems but also contributes to improved system response times, making these bearings particularly valuable in applications requiring rapid and precise movements. The cumulative effect of these improvements has led to more efficient, reliable, and compact mechanical systems across various industries.

What Applications Benefit Most from Type X Thin Section Bearings?

The exceptional versatility and unique performance characteristics of Type X thin section bearings have made them indispensable across a diverse range of industries, with their impact being particularly pronounced in high-precision and space-critical applications. In the aerospace sector, these bearings have revolutionized the design and functionality of satellite positioning systems, where their low-profile construction and precise operation enable more compact and efficient mechanical interfaces. Their implementation in aircraft control surfaces has led to significant weight reductions while maintaining or improving control precision, directly contributing to enhanced fuel efficiency and aircraft performance. The medical equipment industry has particularly benefited from these bearings, especially in advanced imaging technologies like CT scanners, where their thin profile allows for more compact gantry designs while maintaining the smooth, precise rotation necessary for high-quality imaging. Their integration into surgical robots has enabled more precise and controlled movements in minimally invasive procedures, while their use in various diagnostic devices has contributed to improved accuracy and reliability. In the industrial automation sector, these bearings have transformed the capabilities of pick-and-place robots and assembly line equipment, enabling faster operation speeds and greater precision in positioning tasks. The expansive dimensional range of these bearings, spanning from 1 inch to 40 inch bore diameter, ensures their applicability across numerous applications while maintaining the core advantages of their thin-section design.

Technical Specifications and Performance Characteristics

The technical capabilities of Type X thin section bearings represent a significant advancement in bearing engineering, incorporating sophisticated design elements that optimize performance across multiple parameters. Their bidirectional axial load handling capability is achieved through an innovative ball raceway design that efficiently manages forces in both directions, while the enhanced radial load capacity is made possible by optimized internal geometry and superior material selection. The integrated four-point contact design represents a masterful engineering solution that maximizes load distribution efficiency while minimizing bearing cross-section. The carefully calculated ball complement ensures optimal load sharing among bearing elements, resulting in improved load capacity and extended service life. In terms of dimensional specifications, these bearings offer unprecedented flexibility with bore diameters ranging from 1 inch to 40 inches, while maintaining a consistent cross-section that ranges from 0.1875 × 0.1875 inch to 1.000 × 1.000 inch. This consistency across sizes is achieved through precise manufacturing processes that maintain tight tolerances, ensuring reliable performance across all dimensions. The bearings exhibit remarkably low friction coefficients, enabling higher operational speeds while generating less heat. Their improved thermal management characteristics, combined with advanced materials and surface treatments, contribute to extended service life and improved reliability in demanding applications.

Installation and Maintenance Considerations

The optimal performance and longevity of Type X thin section bearings are heavily dependent on proper installation procedures and diligent maintenance practices. Installation requirements demand meticulous attention to detail, beginning with precise alignment specifications that must be carefully followed to ensure optimal bearing performance. The mounting procedures must be executed under controlled conditions, with particular attention paid to cleanliness and environmental factors that could impact bearing operation. Appropriate interference fits must be selected based on specific application requirements, taking into account factors such as operating temperatures, loads, and speed conditions. The clean environment requirements during installation are particularly critical due to the bearings' precision nature and relatively small cross-section. Maintenance protocols play an equally crucial role in ensuring long-term reliability, with regular inspection schedules needed to monitor bearing condition and performance. Lubrication schedules must be carefully planned and executed, taking into consideration operating conditions, environmental factors, and specific application requirements. Temperature monitoring systems should be implemented to detect any thermal anomalies that might indicate potential issues, while regular vibration analysis helps identify potential problems before they develop into serious failures. These comprehensive maintenance guidelines, when properly followed, ensure optimal bearing performance and maximize service life.

Future Developments and Industry Trends

The evolution of Type X thin section bearings continues to drive innovation in the bearing industry, with emerging technologies and new applications constantly expanding their capabilities and potential uses. Advanced materials research is focusing on developing new alloys and composites that offer improved strength-to-weight ratios and enhanced wear resistance. Surface treatment technologies are being refined to provide better protection against corrosion and wear while improving tribological properties. The integration of smart technologies into bearing designs is opening new possibilities for condition monitoring and predictive maintenance, with embedded sensors providing real-time data on bearing performance and health. Enhanced sealing solutions are being developed to improve bearing protection in challenging environments while maintaining the compact design advantages. In terms of industry applications, these bearings are finding new roles in renewable energy systems, where their efficiency and reliability contribute to improved system performance. Their integration into electric vehicle components is enabling more compact and efficient drivetrain designs, while their use in advanced manufacturing equipment is supporting the development of more precise and capable production systems. The continued evolution of robotics technology is creating new opportunities for these bearings, particularly in applications requiring high precision and compact design. These ongoing developments suggest a bright future for Type X thin section bearings, with continued innovation driving improvements in performance, reliability, and application versatility.

Conclusion

Type X thin section bearings represent a significant advancement in bearing technology, offering unprecedented opportunities for system optimization and performance enhancement. Their unique design characteristics, combined with extensive application possibilities, make them an invaluable component in modern mechanical systems.

With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Journal of Tribology (2023). "Advances in Thin Section Bearing Technology"

2. Mechanical Engineering Design Quarterly (2024). "Modern Bearing Solutions for Precision Applications"

3. International Journal of Mechanical Sciences (2023). "Performance Analysis of Four-Point Contact Bearings"

4. Engineering Design Handbook (2024). "Thin Section Bearing Applications in Advanced Systems"

5. Advanced Materials and Processes (2023). "Material Innovations in Bearing Technology"