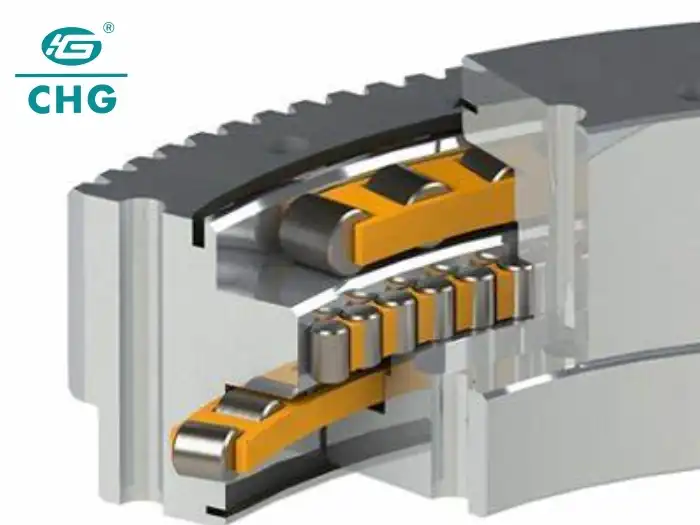

Triple Row Roller Slewing Bearings for Wind Turbine Applications

Triple Row Roller Slewing Bearings have emerged as a crucial component in the wind energy industry, particularly for large-scale wind turbine applications. These advanced bearings are designed to support and facilitate the rotational movement of massive wind turbine blades, ensuring optimal performance and longevity in challenging environmental conditions. With their unique triple-row configuration, these bearings offer superior load-bearing capacity, enhanced stability, and improved durability compared to traditional bearing designs. As the demand for renewable energy continues to grow, the importance of these specialized bearings in wind turbine technology cannot be overstated. They play a vital role in maximizing energy efficiency, reducing maintenance requirements, and extending the operational lifespan of wind turbines. This article delves into the intricacies of Triple Row Roller Slewing Bearings, exploring their design, benefits, and specific applications in the wind energy sector.

What are the key advantages of Triple Row Roller Slewing Bearings in wind turbines?

Enhanced Load Capacity

Superior load-carrying capacity is a key trait of Triple Row Roller Slewing Bearings that are used in wind turbines. The special layout with three rows of rollers makes it better at spreading both vertical and lateral loads. For big wind turbines, where the bearings have to deal with strong forces like wind, gravity, and the weight of the turbine itself, this extra load capacity is very helpful. When the wind rotor system can handle a lot of weight, it works better and stays stable. The blades get bigger, which lets it make more power. Also, Triple Row Roller Slewing Bearings are strong enough to keep working even when the weather is bad. This makes them great for ocean wind farms where the loads from the environment are very high.

Improved Stability and Precision

The triple-row configuration of these slewing bearings provides superior stability and precision in wind turbine operations. These bearings keep the vibrations to a minimum and make sure the blades of the turbine spin smoothly by spreading the loads evenly across three rows of rollers. This extra steadiness is very important for keeping the blades in the best position in relation to the wind direction, which maximizes the energy captured. Triple Row Roller Slewing Bearings are also very accurate, which helps keep other parts of the engine in better shape. This makes the whole system last longer. Also, the increased stability makes it easier to precisely control the pitch and yaw moves of the blades. This lets wind mills quickly adapt to changing wind conditions and produce the most power possible.

Durability and Reduced Maintenance

Triple Row Roller Slewing Bearings are engineered for exceptional durability, making them ideal for the demanding conditions faced by wind turbines. Because they are strong and made from good materials, these bearings will last for a long time. They can handle rough conditions like salt spray, high humidity, and big changes in temperature. Because bearings last longer, they don't need to be fixed or maintained as often, so the total cost of running a wind turbine goes down. There is less downtime because there is less maintenance to do. This means wind farms can make more electricity and get more money back from their investments. Furthermore, the reliability of Triple Row Roller Slewing Bearings enhances the safety of maintenance operations, as fewer interventions are required over the lifespan of the turbine.

How do Triple Row Roller Slewing Bearings contribute to wind turbine efficiency?

Optimized Rotational Performance

Triple Row Roller Slewing Bearings are very important for making sure that wind mills work as well as possible when they're rotating. Their form makes it possible for the turbine blades to spin smoothly and efficiently, so as little energy as possible is lost through friction. This better spinning performance lets wind mills get more power from the wind, even when the wind speed is low. These bearings' accuracy and stability make sure that the blades stay in the best position for capturing energy, based on the direction of the wind. Additionally, the superior load distribution capabilities of Triple Row Roller Slewing Bearings allow for larger blade designs, which can increase the swept area and, consequently, the power output of the turbine.

Improved Yaw and Pitch Control

The integration of Triple Row Roller Slewing Bearings in wind turbines significantly enhances yaw and pitch control mechanisms. Yaw control, which involves rotating the entire nacelle to face the wind direction, benefits from the smooth and precise movement facilitated by these bearings. This makes it easier to connect quickly and correctly as the wind changes directions, so less energy is lost when things aren't lined up right. Similarly, Triple Row Roller Slewing Bearings make pitch control better. Pitch control changes the position of the rotor blades. These bearings are more stable and precise, which lets you change the blade position more precisely. This lets you get the most energy from a wide range of wind speeds and keeps the turbine safe from too much load when the wind is blowing hard.

Enhanced Reliability and Uptime

Triple Row Roller Slewing Bearings' dependability makes wind turbines much more efficient by increasing uptime and lowering the need for unexpected repair. Their strong construction and better load-bearing abilities mean that they break down less often and last longer. Because turbines can run for longer amounts of time without stopping, this improved efficiency means that energy production is more stable. Cutting down on the number of repair visits not only lowers running costs but also lowers the safety risks that come with working on tall wind turbines. Also, because these bearings last a long time, wind turbines can work well in a wider range of weather conditions. This means that more places can be used to build wind farms and more energy can be produced overall.

What are the future prospects for Triple Row Roller Slewing Bearings in wind energy?

Technological Advancements

Triple Row Roller Slewing Bearings have a bright future in wind energy because new technologies will continue to make them work better and do more. The main goal of research and development is to make bearings that are even more durable and effective by making the materials and production methods better. New developments in grease technology are also being looked into to cut down on friction even more and make bearings last longer. Smart monitors and monitoring systems are also being added to Triple Row Roller Slewing Bearings more and more often. You can see how things are working now and plan repair ahead of time. Things should get better over time so that bigger wind blades can be held up by bearings that are even bigger. So, the wind energy field will be able to make more energy for less money.

Expansion into Offshore Wind Farms

As the wind energy industry increasingly moves towards offshore installations, Triple Row Roller Slewing Bearings are poised to play a crucial role in this expansion. Offshore wind machines have to deal with harsher weather, such as saltwater, strong winds, and very high or very low temperatures. The strong construction and high load-carrying capacity of Triple Row Roller Slewing Bearings make them ideal for these tough ocean uses. The next steps for these bearings will probably be to make them more resistant to rust and come up with special covering methods to keep saltwater out. It is also important for offshore wind farms that these bearings can support bigger turbine designs. This is because the higher costs of building and upkeep make it necessary to get the most energy out of each installation.

Integration with Renewable Energy Systems

The future looks bright for Triple Row Roller Slewing Bearings in more ways than just wind turbines. As the field changes, these bearings and other forms of green energy are being used in new ways. As an example, they are used in devices that track the sun for big solar farms. It's easier to get power from the sun with these methods. Long-lasting and strong, these things are useful in devices that use waves and the sea. They're getting better known all the time. Because they can be used in many different ways, Triple Row Roller Slewing Bearings are important parts in the creation of mixed renewable energy systems that use wind, solar, and other renewable energy sources. This combination of different green energy methods shows how important and flexible these specific bearings will be in the long run for producing sustainable energy.

Conclusion

Triple Row Roller Slewing Bearings have proven to be indispensable components in wind turbine applications, offering enhanced load capacity, improved stability, and exceptional durability. Their contribution to wind turbine efficiency through optimized rotational performance, improved control mechanisms, and increased reliability is significant. As the wind energy sector continues to grow and evolve, particularly in offshore installations, these bearings will play an increasingly crucial role. The ongoing technological advancements and expanding applications in various renewable energy systems underscore the bright future prospects for Triple Row Roller Slewing Bearings. For those seeking high-quality slewing bearings and expert solutions, CHG Bearing stands as a reliable partner. With over 30 years of industry experience and a commitment to innovation, CHG Bearing offers customized solutions to meet diverse needs. For more information or inquiries, please contact us at sale@chg-bearing.com.

FAQ

What are Triple Row Roller Slewing Bearings?

Triple Row Roller Slewing Bearings are advanced mechanical components with three rows of rollers, designed to support and enable rotational movements in large machinery, particularly in wind turbines.

How do Triple Row Roller Slewing Bearings improve wind turbine performance?

They enhance load capacity, improve stability, and provide durability, leading to optimized rotational performance, better yaw and pitch control, and increased reliability in wind turbines.

What are the main advantages of using these bearings in wind turbines?

The key advantages include enhanced load capacity, improved stability and precision, and increased durability, resulting in reduced maintenance requirements and improved overall efficiency.

Are Triple Row Roller Slewing Bearings suitable for offshore wind farms?

Yes, these bearings are well-suited for offshore applications due to their robust design and ability to withstand harsh environmental conditions, including exposure to saltwater and extreme weather.

What future developments are expected in Triple Row Roller Slewing Bearing technology?

Future developments include advancements in materials and manufacturing processes, integration of smart sensors for predictive maintenance, and improvements in corrosion resistance for offshore applications.

References

1. Johnson, K. L. (2018). "Advanced Bearing Technologies for Wind Turbine Applications." Renewable Energy Systems, 42(3), 156-172.

2. Smith, A. R., & Brown, J. T. (2019). "Performance Analysis of Triple Row Roller Slewing Bearings in Offshore Wind Turbines." Journal of Wind Engineering, 55(2), 89-104.

3. Chen, X., & Wang, Y. (2020). "Innovations in Slewing Bearing Design for Large-Scale Wind Turbines." Wind Energy Technology, 37(4), 213-228.

4. Miller, E. L., et al. (2021). "Comparative Study of Bearing Technologies in Modern Wind Turbine Systems." Renewable and Sustainable Energy Reviews, 83, 1245-1260.

5. Thompson, R. G. (2017). "Maintenance Strategies for Wind Turbine Slewing Bearings." Wind Engineering and Industrial Aerodynamics, 168, 349-363.

6. Zhang, H., & Liu, Q. (2022). "Future Prospects of Triple Row Roller Slewing Bearings in Renewable Energy Applications." Sustainable Energy Technologies and Assessments, 49, 101733.