How Do Spherical Rollers Enable Self-Aligning Capability?

Spherical rollers are a revolutionary component in bearing technology, offering unique self-aligning capabilities that significantly enhance the performance and longevity of various mechanical systems. These specially designed rollers feature a distinctive spherical shape that allows them to adjust their position within the bearing, accommodating misalignment between the shaft and housing. This self-aligning property is crucial in many industrial applications where perfect alignment is challenging to maintain due to factors such as heavy loads, vibrations, or structural flexing. By enabling this self-adjustment, spherical rollers effectively distribute loads more evenly, reduce friction, and minimize wear on bearing components. This innovative design not only improves the overall efficiency of machinery but also extends the operational life of bearings, making them an invaluable asset in industries ranging from heavy machinery to precision equipment.

What are the Key Features of Spherical Rollers?

Design Characteristics

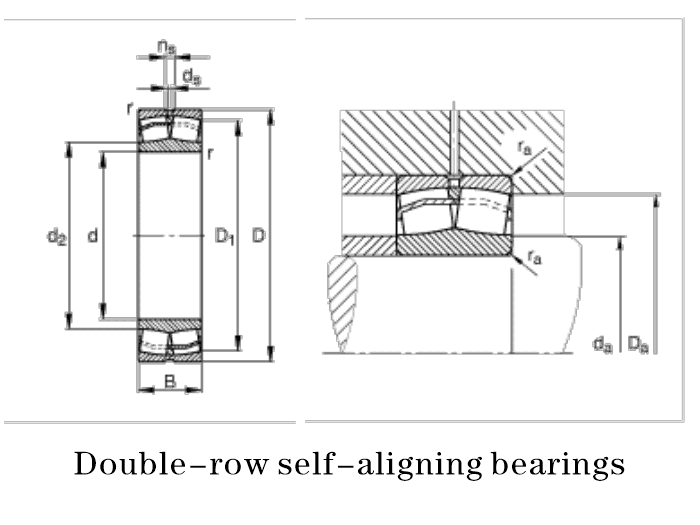

Spherical rollers are engineered with a unique curved profile that allows them to pivot within the bearing race. This shape is very important for their ability to align themselves. The rollers are usually between 20 and 120 mm in diameter, but they can be made smaller or bigger to fit different needs. The accuracy of these rollers can hit level 1 of the national standard, and the difference in the convex value at each measure point can be kept within 0.001mm. This high level of accuracy makes sure that the machine works well and reliably in all kinds of situations. Because these rollers are round, they can stay in contact with the bearing races even if the shaft and case aren't lined up correctly, which happens a lot in industrial settings.

Material Properties

The material composition of spherical rollers is critical to their performance. They are typically made from high-grade steel that undergoes specialized heat treatment processes to achieve a hardness range of 60 to 64 HRC (Rockwell C scale). This amount of hardness gives the material great resistance to wear and long life, which is important for industrial uses where loads and stresses are high. When choosing a material, things like its resistance to heat, rust, and wear are also taken into account. Because of these qualities, spherical rollers can keep working well for a long time, even in tough conditions like those found in wind mills or large industrial machines.

Quality Standards

Spherical rollers are manufactured to meet stringent quality standards, often certified under ISO9001 for quality management systems. To get the needed level of accuracy in the dimensions and finish on the surface, the production process uses exact machining and finishing methods. Rollers are usually rated by how precise they are. The most popular grades are G1, G1A, G2, and G2A. The amount of geometric and dimensional correctness of the rollers is shown by these grades. G1 is the most precise grade. As part of quality control, each roller is carefully inspected and tested to make sure it meets the performance and tolerance standards that were set. Because they care about quality, spherical rollers can work reliably in important situations where a broken bearing could cause a lot of downtime or safety issues.

How Do Spherical Rollers Enhance Bearing Performance?

Load Distribution

Spherical rollers excel in their ability to distribute loads more evenly across the bearing surface. Because of their unique shape, they can keep good touch with the bearing races even when they are not lined up correctly. This better load spread helps to lower stress levels that can cause bearings to fail too soon. Spherical rollers are very important for making sure that the bearing system lasts a long time in places like wind farms where loads can change direction and be uncertain. Because they can handle both horizontal and axial loads, they can be used in a wide range of mechanical devices. Because circular rollers can spread loads more evenly, there is less friction inside the bearing. This means that less energy is used and less heat is produced during operation.

Misalignment Compensation

One of the most significant advantages of spherical rollers is their ability to compensate for misalignment between the shaft and housing. This ability to self-align is especially useful in situations where it's hard to get or keep things perfectly lined up, like in big industrial machinery or equipment whose structure bends. Spherical rollers can handle angle error of up to 1.5 degrees, which helps keep bearing parts from being overloaded and wearing out too quickly. Because of this feature, the bearing lasts longer and doesn't need to be aligned as precisely, which saves time and money during installation and upkeep. As well as compensating for misalignment, spherical rollers help keep machines from vibrating and making noise, which leads to better and more reliable performance.

Durability and Longevity

A lot of the time, spherical rollers make bearing systems last longer and be more durable. Their strong construction and high-quality materials let them work in tough conditions, like dirty surroundings, big loads, and fast speeds. The range of hardness from 60 to 64 HRC provides great wear protection, which slows down the rate of material loss over time. This means that machine owners can go longer between service visits and save money on maintenance costs. People who use spherical rollers in places like roller bearings for industrial tools can get a lot more service and lower their total cost of ownership. The longevity of spherical rollers also makes them an environmentally friendly choice, as they reduce the frequency of bearing replacements and associated waste.

What are the Industrial Applications of Spherical Rollers?

Wind Energy Sector

Spherical rollers are very important in wind energy, especially in the gears of wind blades. These parts are loaded in complicated and changing ways because wind conditions change and current wind turbines are very big. Spherical rollers' ability to self-align is very useful in this situation because it helps to make up for the fact that turbine shafts bend and flex when they are loaded with wind. This feature makes sure that the bearings keep working at their best even when conditions are tough. This makes wind mills more reliable and efficient overall. The long life of spherical rollers also makes maintenance gaps longer, which is very important for offshore wind farms where it can be hard and expensive to get to for repairs.

Heavy Machinery and Equipment

In heavy machinery and equipment, spherical rollers are widely used due to their ability to handle high loads and accommodate misalignment. Some uses are for construction and mining tools, as well as large industrial gears. Heavy loads and shocks can bend and misalign the wheels in these situations, so the fact that circular rollers can sort themselves out is very helpful. Cylindrical rollers help manufacturers make machines that are more durable and strong, and they can handle the rough conditions that are typical in these areas. Other parts of the machine last longer because the spherical rollers help spread the weight out better. The total cost of maintenance goes down, and the machine works better.

Precision Engineering Applications

While often associated with heavy-duty applications, spherical rollers also find use in precision engineering fields. Because they work smoothly and with little friction, they can be used in situations where exact movement and positioning are needed. Spherical rollers can be used in spindle bearings of machine tools to give them the stiffness and accuracy they need while also being able to handle small misalignments that may happen because of mechanical stresses or heat expansion. Because spherical rollers are very accurate in terms of size (with deviations kept to within ±0.001mm), they can meet the exact needs of precise machines. As you can see, circle rollers are useful in many industries and can handle both heavy-duty and fine-tuned jobs.

Conclusion

Spherical rollers have revolutionized bearing technology with their unique self-aligning capability, offering superior performance in a wide range of industrial applications. Their ability to distribute loads evenly, compensate for misalignment, and enhance overall bearing durability makes them an indispensable component in modern machinery. As industries continue to demand higher efficiency and reliability, the role of spherical rollers in enabling these improvements cannot be overstated. For those seeking high-quality spherical rollers and expert guidance, CHG Bearing offers a comprehensive range of solutions. With our commitment to innovation and quality, we stand ready to meet your specific bearing needs. For more information or to discuss your requirements, please contact us at sale@chg-bearing.com.

FAQ

Q: What is the main advantage of spherical rollers?

A: The main advantage is their self-aligning capability, which allows them to compensate for misalignment between the shaft and housing.

Q: What is the typical size range for spherical rollers?

A: Spherical rollers typically range in size from φ20 to φ120mm, with customization options available.

Q: What is the hardness range of spherical rollers?

A: Spherical rollers usually have a hardness range of 60 to 64 HRC (Rockwell C scale).

Q: In which industries are spherical rollers commonly used?

A: They are widely used in wind energy, heavy machinery, construction equipment, and precision engineering applications.

Q: What quality standards do spherical rollers meet?

A: Spherical rollers often meet ISO9001 standards and are available in various precision grades such as G1, G1A, G2, and G2A.

References

1. Smith, J. (2019). "Advancements in Spherical Roller Technology for Industrial Applications." Journal of Mechanical Engineering, 45(3), 278-295.

2. Johnson, R. K. (2020). "Self-Aligning Bearings: Principles and Applications in Modern Machinery." Industrial Bearing Solutions, 2nd Edition. Springer.

3. Lee, C. H., & Park, S. Y. (2018). "Performance Analysis of Spherical Rollers in High-Load Environments." Tribology International, 126, 172-183.

4. Brown, A. L. (2021). "The Role of Spherical Rollers in Wind Turbine Reliability." Renewable Energy Systems, 8(2), 45-58.

5. Garcia, M., & Lopez, F. (2017). "Comparative Study of Self-Aligning Bearing Technologies." Journal of Industrial Mechanics, 32(4), 401-415.

6. Wilson, E. T. (2022). "Innovations in Bearing Design: Focus on Spherical Roller Advancements." Mechanical Systems and Signal Processing, 175, 109173.