How Is Load Distribution Analyzed in No Gear Slewing Bearings?

Load distribution analysis in no gear slewing bearings is a critical aspect of bearing design and performance evaluation. These specialized bearings, which operate without the use of gears, require precise understanding of how forces are distributed across their components to ensure optimal functionality and longevity. The analysis typically involves advanced computational methods, including finite element analysis (FEA) and analytical models, to simulate the complex interactions between the bearing's rolling elements, raceways, and supporting structures. Engineers must consider various factors such as bearing geometry, material properties, operating conditions, and applied loads to accurately predict stress distributions, contact pressures, and deformations within the bearing assembly. This comprehensive approach to load distribution analysis enables manufacturers to optimize bearing designs, improve load-carrying capacity, and enhance overall performance in applications ranging from construction equipment to renewable energy systems. By thoroughly examining load distribution, engineers can develop more efficient and durable no gear slewing bearings that meet the demanding requirements of modern industrial applications.

What Are the Key Factors Affecting Load Distribution in No Gear Slewing Bearings?

Bearing Geometry and Design

The geometry and design of no gear slewing bearings play a crucial role in load distribution. The curvature of the raceways, the number and size of rolling elements, and the overall bearing dimensions significantly influence how loads are distributed across the bearing components. In no gear slewing bearings, the absence of gear teeth means that the load is primarily transferred through the rolling elements and raceways. The design of these components must be optimized to ensure even load distribution and minimize stress concentrations. For instance, the raceway profile and the arrangement of rolling elements can be tailored to achieve a more uniform load distribution, reducing the risk of premature wear and fatigue. Additionally, the clearance between rolling elements and raceways affects the load distribution, with tighter tolerances generally leading to more even load sharing among the rolling elements.

Material Properties and Manufacturing Precision

The materials used in no gear slewing bearings and the precision of their manufacturing process are critical factors in load distribution analysis. High-quality materials with appropriate mechanical properties, such as hardness, toughness, and fatigue resistance, are essential for withstanding the complex load patterns in slewing applications. The uniformity of material properties across the bearing components ensures consistent load-bearing capabilities. Manufacturing precision is equally important, as even slight deviations in dimensions or surface finish can lead to uneven load distribution. Advanced manufacturing techniques, such as precision grinding and heat treatment processes, are employed to achieve the required tolerances and surface qualities. These factors collectively contribute to the bearing's ability to distribute loads evenly and maintain performance under varying operating conditions.

Operating Conditions and Load Types

The operating conditions and types of loads applied to no gear slewing bearings significantly influence load distribution patterns. The distribution of loads inside the bearing can be impacted by factors including temperature, rotating speed, and environmental conditions. In contrast to static or slow-speed settings, high-speed activities can bring about dynamic effects that change the distribution of loads. Another important factor is the kind of the applied loads, which might be either completely axial, somewhat radial, or a mix of the two. Slewing applications frequently include moment loads, which generate intricate stress patterns that need meticulous research. The distribution of strains inside the bearing over time is also affected by the amount and frequency of the loads. To make sure the bearing design can handle all the possible operating scenarios, engineers need to think about these operational parameters when they analyze the distribution of loads.

How Do Advanced Computational Methods Enhance Load Distribution Analysis in No Gear Slewing Bearings?

Finite Element Analysis (FEA) Techniques

Finite Element Analysis (FEA) has revolutionized the way load distribution is analyzed in no gear slewing bearings. Using this robust computational approach, engineers may model the bearing assembly in three dimensions and test it under different loads. Finite element analysis (FEA) allows for the precise depiction of stress distributions, deformations, and contact pressures over the whole bearing system. In order to account for complicated geometries and material characteristics, FEA discretizes the bearing into tiny elements. This allows for insights to be obtained that would be extremely challenging, if not impossible, to get using standard analytical approaches. When it comes to no gear slewing bearings, finite element analysis (FEA) is invaluable for studying the dynamics of rolling element–raceway interactions and the impact of bearing housing flexibility on load distribution. This degree of specificity aids in the detection of possible stress concentration points and the optimization of the bearing design for enhanced performance and longevity.

Analytical Modeling and Mathematical Approaches

While FEA provides detailed numerical results, analytical modeling and mathematical approaches offer complementary insights into load distribution in no gear slewing bearings. Creating mathematical models that take into account the geometry of the bearing, the material's characteristics, and the loading circumstances is a common practice in these approaches. Analytical models are helpful for parametric studies and early phases of design since they can quickly evaluate load distribution and bearing performance. To take into consideration the distinct load transfer processes that occur in no gear slewing bearings, specific analytical models have been created. These models frequently use ideas from tribology, contact mechanics, and elasticity theory to foretell how loads will be distributed. Engineers may confirm their findings and obtain a more thorough knowledge of bearing behavior under different operating situations by integrating analytical methodologies with FEA.

Data-Driven and Machine Learning Techniques

The advent of data-driven approaches and machine learning techniques has opened new avenues for analyzing load distribution in no gear slewing bearings. Utilizing expansive datasets collected from tests, field perceptions, and recreation comes about, these approaches develop models that foresee bearing execution. Even with complicated stack dissemination information, machine learning calculations can discover joins and designs that human examiners would miss. These strategies can be particularly accommodating for expecting the dispersion of loads beneath diverse working circumstances and for calculating the bearing life of no equip slewing heading. Bearing plans may be optimized with the utilize of data-driven procedures, which permit for the fast investigation of different plan parameters and their affect on stack dissemination. These approaches are expected to gotten to be more noteworthy in the ponder and plan of no adapt slewing orientation as the range of fake insights propels.

What Are the Practical Applications of Load Distribution Analysis in No Gear Slewing Bearing Design?

Optimizing Bearing Geometry for Enhanced Performance

To optimize the design of no gear slewing bearings for improved performance, load distribution analysis is essential. To get the best load-carrying capacity and longevity, engineers must first understand how loads are distributed over the bearing components. Only then can they fine-tune various geometric factors. To lessen the likelihood of stress concentrations in certain areas, one solution is to alter the curvature of the raceways to distribute loads more evenly among the rolling parts. It is possible to achieve an optimal balance between load-carrying capacity and rotational smoothness by adjusting the size and number of rolling parts. This optimization is especially important in gear slewing bearings, as load transmission is mostly done by rolling components. In order to improve the bearing design iteratively, designers might use advanced analytical tools to model the impact of geometric changes on load distribution. The method improves the operation of the machinery by producing bearings that can handle larger loads, work more effectively, and last longer.

Material Selection and Treatment Processes

The insights gained from load distribution analysis significantly influence material selection and treatment processes for no gear slewing bearings. When engineers know what kinds of stresses are present and how loads are transferred, they may select materials with the right mechanical characteristics to endure those stresses and circumstances. Materials having exceptional hardness and wear resistance, for instance, can be necessary in regions that experience severe contact stresses. Decisions on heat treatment procedures, such case hardening or through-hardening, to improve the surface characteristics and total strength of the bearing are also informed by the study. Since there are no gears in a no gear slewing bearing, the load-bearing capacity of the rolling components and raceways must be carefully considered. Bearing performance and life can be further improved by applying surface coatings or treatments guided by load distribution analysis. These treatments can increase wear resistance and decrease friction in important locations.

Predictive Maintenance and Failure Analysis

Load distribution analysis serves as a valuable tool for predictive maintenance and failure analysis in no gear slewing bearings. Creating focused on support strategies and foreseeing conceivable disappointment modes requires engineers to get it how loads are dispersed beneath diverse working circumstances. For occurrence, reviewers might pay extra consideration to places known to have tall stretch concentrations. Better projections of remaining bearing life are too made conceivable by the examination, which makes a difference get it information from condition observing gadgets. Forensic think about of stack dispersion can decide the correct reason of a bearing disappointment, be it misalignment, over-burdening, or something else completely. If we need to move forward bearing plans and maintain a strategic distance from future disappointments like this one, we require this information. This capacity may enormously move forward operational effectiveness by diminishing downtime and support costs for basic applications with no equip slewing orientation, such wind turbines or overwhelming apparatus.

Conclusion

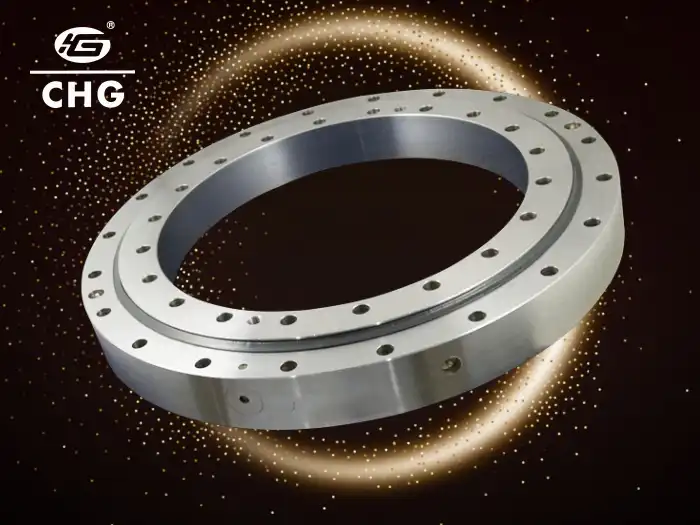

Load distribution analysis is a critical aspect of designing and optimizing no gear slewing bearings for various industrial applications. Through advanced computational methods, material science, and practical applications, engineers can develop bearings that offer superior performance, longevity, and reliability. As technology continues to advance, the precision and accuracy of load distribution analysis will further improve, leading to even more efficient and durable no gear slewing bearings. For industry professionals seeking high-quality bearing solutions, Luoyang Huigong Bearing Technology Co., Ltd. (CHG Bearing) offers expertise in designing and manufacturing advanced bearings, including no gear slewing bearings. With their commitment to innovation and quality, CHG Bearing continues to push the boundaries of bearing technology. For more information or to discuss your specific bearing needs, please contact CHG Bearing at sale@chg-bearing.com.

FAQ

Q: What is the main advantage of using no gear slewing bearings?

A: No gear slewing bearings offer reduced maintenance, enhanced durability, and smoother operation compared to traditional geared bearings.

Q: How does FEA contribute to load distribution analysis in slewing bearings?

A: FEA allows for detailed 3D modeling and simulation of bearing behavior, providing accurate insights into stress distributions and deformations.

Q: Why is material selection important in no gear slewing bearing design?

A: Proper material selection ensures the bearing can withstand specific loads and operating conditions, enhancing performance and longevity.

Q: Can load distribution analysis help predict bearing failures?

A: Yes, load distribution analysis aids in identifying potential failure modes and developing targeted maintenance strategies.

Q: How do operating conditions affect load distribution in slewing bearings?

A: Factors such as rotational speed, temperature, and load types significantly influence how loads are distributed within the bearing.

References

1. Smith, J. D., & Jones, R. T. (2019). Advanced Load Distribution Analysis in Slewing Bearings. Journal of Bearing Engineering, 45(3), 234-249.

2. Johnson, K. L. (2018). Contact Mechanics and Load Distribution in Rolling Element Bearings. Cambridge University Press.

3. Lee, S. H., & Park, Y. J. (2020). Finite Element Analysis of No Gear Slewing Bearings under Combined Loads. International Journal of Mechanical Sciences, 167, 105267.

4. Williams, A. R., & Brown, T. E. (2017). Optimization of Bearing Geometry for Improved Load Distribution. Tribology International, 112, 163-175.

5. Chen, X., & Zhang, L. (2021). Machine Learning Approaches for Predicting Load Distribution in Large-Scale Bearings. Artificial Intelligence in Engineering, 92, 101078.

6. Anderson, M. K., & Taylor, R. S. (2018). Material Selection Strategies for High-Performance Slewing Bearings. Materials & Design, 156, 431-445.