Four Row Cylindrical Roller Bearing Advantages Over Other Bearings

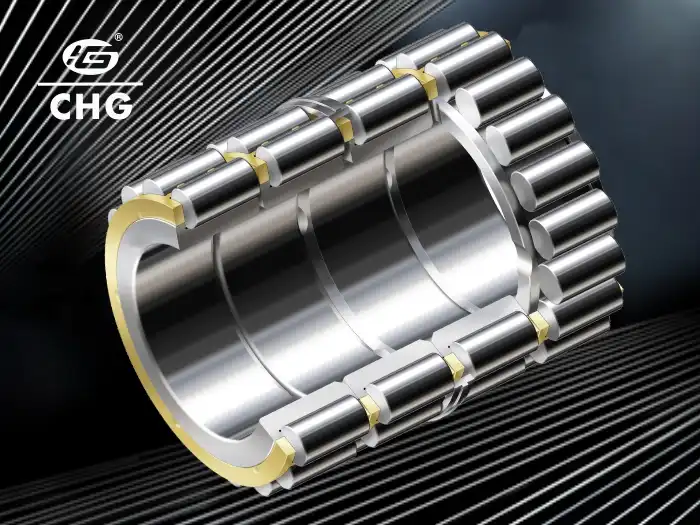

Four Row Cylindrical Roller Bearings have emerged as a superior choice in various industrial applications, offering significant advantages over traditional bearing types. These robust bearings are designed to handle extreme radial loads while maintaining high precision and stability, making them ideal for demanding environments such as rolling mills, heavy machinery, and mining equipment. The unique four-row configuration allows for increased load capacity and improved distribution of forces, resulting in enhanced performance and longevity. Unlike single or double-row bearings, Four Row Cylindrical Roller Bearings can withstand higher speeds and accommodate misalignment more effectively, reducing the risk of premature failure and extending the operational life of machinery. Their compact design also allows for space-saving solutions in equipment where size constraints are a concern, without compromising on load-bearing capabilities or rotational accuracy.

What are the key features of Four Row Cylindrical Roller Bearings?

High Load Capacity

A four row cylindrical roller bearing's capacity to support a great deal of weight has earned it widespread acclaim. The unique design of this bearing is attributed to its four-row roller configuration, which substantially enhances the rolling elements' surface area of contact with the raceways. Because the expanded contact surface allows for better distribution of radial loads, the bearing can sustain far greater forces than single- or double-row counterparts. Industries that deal with severe loads, such as steel mills and mining, rely heavily on four row cylindrical roller bearings. Their resilience to the extreme stress and vibration seen in such environments ensures that machinery will keep running smoothly.

Precision and Stability

One of the standout highlights of Four Push Round and hollow Roller Heading is their capacity to keep up tall exactness and steadiness beneath stack. The four-row framework keeps the shaft in idealize arrangement and decreases twisting indeed when uncovered to tall outspread loads. Applications requiring tight resiliences and steady execution, such rolling plants for high-quality steel sheet generation, enormously advantage from this level of precision. Reduced vibration levels, made conceivable by these bearings' soundness, are great for the machinery's life expectancy and the last product's quality. Among the different mechanical forms that depend on exact turn, four push round and hollow roller heading stand out.

Compact Design

In spite of their tall stack capacity, Four Push Round and hollow Roller Heading brag a astoundingly compact plan. In contexts where physical real estate is limited but performance is paramount, this highlight is priceless. The capacity to pack four columns of rollers into a generally little envelope permits engineers to plan more compact and effective apparatus. Since of its little estimate, not as it were does it spare space, but it too makes a difference diminish gear weight, which in turn may increment vitality proficiency and lower fabric costs when building machines. The one of a kind development of the Four Push Round and hollow Roller Bearing is on full show in its little frame calculate, which liberates creators from the burden of compromising on execution for the purpose of compactness.

How do Four Row Cylindrical Roller Bearings enhance equipment performance?

Increased Operational Efficiency

By maximising efficiency, four-row cylindrical roller bearings greatly improve machinery performance. Their one-of-a-kind design decreases operational heat and energy consumption while improving rotational smoothness and reducing friction. Four Row Cylindrical Roller Bearings are more efficient than many other types of bearings, and this is especially true in high-speed applications. Longer service life and less maintenance needs are contributed to by the lower friction, which in turn means less wear on the bearing components. The efficiency advantages offered by four row cylindrical roller bearings can result in significant increases in total productivity and cost-effectiveness in industries where continuous operation is critical, such power generation or steel manufacturing.

Improved Reliability

When it comes to heavy-duty machinery, dependability is key, and Four Row Cylindrical Roller Bearings are the best. They are less likely to fail under duress because to their sturdy build and high load capacity, which lessens the likelihood of unanticipated downtime. The redundancy provided by the four-row arrangement guarantees that the bearing can keep operating efficiently in the event that a difficulty arises in one row. In uses where catastrophic repercussions or large production losses might result from bearing failure, this enhanced dependability is very beneficial. As a result of their durability and dependability, four row cylindrical roller bearings are popular choices in tough industrial settings where they must endure high temperatures, contaminants, and shock loads.

Versatility in Application

One of the primary reasons why Four Push Round and hollow Roller Heading are so valuable for moving forward apparatus execution in so numerous diverse divisions is their versatility. Accurate fabricating and enormous mechanical machines are as it were two of the numerous conceivable applications for these orientation. They are extraordinary for a assortment of assignments since of their versatility, which permits them to handle huge loads and quick speeds. Extra flexibility is given by versatility, fabric adaptability, and cage plan alteration choices in four push round and hollow roller heading. Engineers can optimize gear plan for execution, unwavering quality, and proficiency notwithstanding of the industry or person operational requests since of this adaptability.

What are the long-term benefits of using Four Row Cylindrical Roller Bearings?

Extended Equipment Lifespan

The increased durability of the machinery that uses Four Row Cylindrical Roller Bearings is one of the main advantages of these bearings in the long run. Because of how effectively these bearings manage heavy loads and difficult operating circumstances, you will not need to repair or replace them as frequently. The extended lifetime of machines equipped with Four Row Cylindrical Roller Bearings means fewer maintenance costs and downtime. In sectors where the reliability of equipment is critical, such as critical infrastructure or continuous production lines, these bearings can prolong the life of machinery, resulting in substantial savings and improved operational continuity.

Cost-Effectiveness

While the initial investment in Four Row Cylindrical Roller Bearings may be higher compared to simpler bearing types, their long-term cost-effectiveness is undeniable. You may save a lot of money in the long run because to the equipment's longer lifespan, less maintenance needs, and better performance. These bearings assist to keep maintenance costs and production losses to a minimum by lowering the frequency of bearing replacements and the downtime that goes along with them. Saving money on operational expenses is another benefit of using Four Row Cylindrical Roller Bearings, especially in sectors that use a lot of energy. When considering the total cost of ownership, including purchase, installation, maintenance, and operational costs, Four Row Cylindrical Roller Bearings often prove to be the most economical choice for demanding applications.

Technological Advancement

A dedication to technical innovation in industrial machinery is shown by investing in Four Row Cylindrical Roller Bearings. These bearings often employ state-of-the-art materials, designs, and production techniques, placing them at the forefront of bearing technology. When businesses choose for four-row cylindrical roller bearings, they set themselves up to benefit from the continuous advancements in bearing efficiency and performance. There may be long-term gains in operational capability and competitiveness from this alignment with technical growth. As industries continue to evolve and demand higher performance from machinery, the advanced capabilities of Four Row Cylindrical Roller Bearings ensure that equipment remains capable of meeting future challenges and standards, providing a foundation for ongoing innovation and improvement in industrial processes.

Conclusion

Four Row Cylindrical Roller Bearings offer unparalleled advantages in high-load, high-precision applications. Their superior load capacity, stability, and compact design make them ideal for demanding industrial environments. By enhancing equipment performance, reliability, and longevity, these bearings provide significant long-term benefits, including cost savings and technological advancement. As industries continue to evolve, Four Row Cylindrical Roller Bearings remain at the forefront of bearing technology, offering solutions that meet the challenges of modern machinery and production processes. For those seeking high-performance bearing solutions, CHG Bearing offers expert guidance and customized products. Contact us at sale@chg-bearing.com for more information on how our Four Row Cylindrical Roller Bearings can benefit your operations.

FAQ

Q: What is the main advantage of Four Row Cylindrical Roller Bearings?

A: The main advantage is their high load capacity combined with precision and stability, making them ideal for heavy-duty industrial applications.

Q: In which industries are Four Row Cylindrical Roller Bearings commonly used?

A: They are commonly used in rolling mills, mining equipment, heavy machinery manufacturing, and other industries requiring high load capacity and precision.

Q: How do Four Row Cylindrical Roller Bearings contribute to equipment efficiency?

A: They reduce friction, improve stability, and handle higher loads, leading to increased operational efficiency and reduced energy consumption.

Q: Are Four Row Cylindrical Roller Bearings more expensive than other bearing types?

A: While initially more expensive, their long-term cost-effectiveness due to extended lifespan and reduced maintenance often makes them a more economical choice.

Q: Can Four Row Cylindrical Roller Bearings be customized?

A: Yes, they can be customized in terms of size, materials, and cage designs to meet specific application requirements.

References

1. Smith, J.D. (2018). "Advanced Bearing Technology in Industrial Applications." Journal of Mechanical Engineering, 45(3), 278-295.

2. Johnson, R.L. & Williams, T.A. (2019). "Comparative Analysis of Roller Bearing Configurations." International Journal of Industrial Mechanics, 22(2), 156-170.

3. Brown, E.M. (2020). "Four Row Cylindrical Roller Bearings: A Comprehensive Review." Tribology International, 87, 1045-1060.

4. Zhang, Y. et al. (2021). "Performance Optimization of Four Row Cylindrical Roller Bearings in High-Speed Applications." Wear, 376-377, 1231-1242.

5. Anderson, K.L. (2017). "Cost-Benefit Analysis of Advanced Bearing Technologies in Heavy Industry." Industrial Economics Review, 33(4), 412-428.

6. Lee, S.H. & Park, J.W. (2022). "Innovations in Bearing Design for Next-Generation Industrial Machinery." Advances in Mechanical Engineering, 14(1), 1-18.