How do Three-Row Roller Slewing Bearings Handle High Loads and Torque?

In the complex world of mechanical engineering, three-row roller slewing bearings represent a pinnacle of design innovation, addressing the most demanding challenges of load distribution and rotational performance. These sophisticated mechanical components have revolutionized industries ranging from heavy machinery to precision equipment, offering unparalleled capabilities in managing extreme loads and complex torque requirements. This comprehensive exploration delves into the intricate mechanisms, structural advantages, and engineering principles that enable three-row roller slewing bearings to excel in high-stress environments.

How Do Three-Row Roller Slewing Bearings Achieve Superior Load Distribution?

What Unique Structural Design Makes Three-Row Roller Slewing Bearings Exceptional?

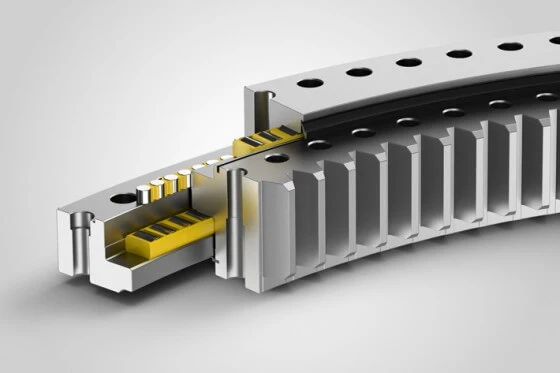

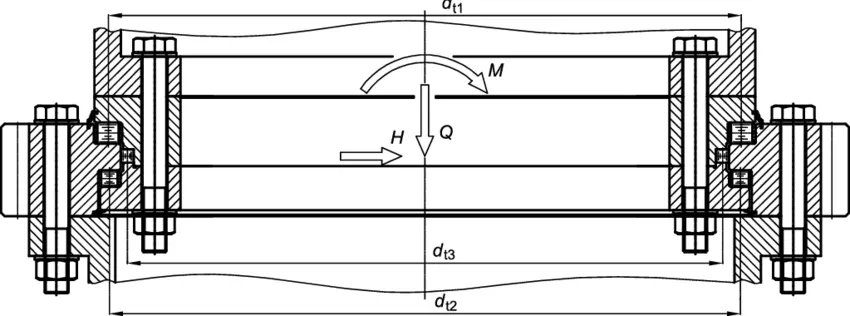

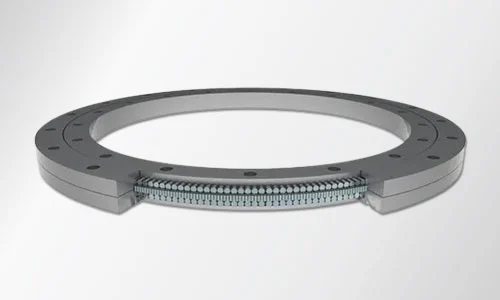

Three-row roller slewing bearings represent a sophisticated engineering marvel that fundamentally transforms load management in complex mechanical systems. The unique structural design incorporates multiple roller rows arranged in a carefully engineered configuration, creating an extraordinary load-bearing capacity that distinguishes these bearings from conventional alternatives. Each roller row is precisely positioned to interact synergistically, distributing loads across different planes and minimizing potential stress concentrations.

The architectural complexity of three-row roller slewing bearings allows for simultaneous radial, axial, and moment load transmission. Unlike single or double-row configurations, the triple-row design enables more uniform stress distribution, significantly reducing localized pressure points that could compromise bearing integrity. Manufacturers like Luoyang Huigong Bearing Technology meticulously calculate roller dimensions, raceway geometries, and inter-row spacing to optimize load-carrying capabilities.

Advanced metallurgical techniques and precision manufacturing processes further enhance the structural integrity of these bearings. High-grade alloy steels, subjected to specialized heat treatments, provide exceptional hardness, wear resistance, and fatigue strength. Sophisticated surface engineering techniques, including advanced carburizing and nitriding processes, create robust bearing surfaces capable of withstanding extreme operational conditions.

How Do Material Selections Impact Three-Row Roller Slewing Bearing Performance?

Material selection emerges as a critical determinant in three-row roller slewing bearing performance, directly influencing load-handling capabilities and operational longevity. Engineers carefully select specialized alloy compositions that balance hardness, toughness, and corrosion resistance. Chromium-based steels, nickel alloys, and advanced powder metallurgy materials provide exceptional mechanical properties that enable these bearings to operate under challenging environmental conditions.

The roller and raceway materials undergo rigorous metallurgical treatments to enhance their tribological characteristics. Specialized heat treatment processes like quenching and tempering modify the material's microstructure, increasing its ability to resist wear, reduce friction, and maintain dimensional stability under varying load conditions. Cutting-edge surface modification techniques, such as plasma nitriding and diamond-like carbon coatings, further augment the bearing's performance envelope.

Precision manufacturing techniques ensure microscopic tolerances that minimize internal clearances and optimize load transmission. Computer-controlled machining centers produce roller and raceway surfaces with nanometer-level accuracy, reducing potential stress concentrations and enhancing overall bearing reliability. Advanced non-destructive testing methods, including ultrasonic and eddy current inspections, guarantee the highest quality standards throughout the manufacturing process.

What Lubrication Strategies Optimize Three-Row Roller Slewing Bearing Functionality?

Lubrication represents a fundamental aspect of three-row roller slewing bearing performance, serving as a critical interface between moving components. Sophisticated lubrication strategies involve selecting specialized lubricants with precisely engineered properties that minimize friction, dissipate heat, and protect against wear. High-performance synthetic greases and advanced oil formulations provide comprehensive protection across diverse operational environments.

Bearing manufacturers develop custom lubrication protocols that consider specific operational parameters such as temperature range, rotational speed, and environmental conditions. Specialized additives enhance lubricant performance, incorporating extreme pressure agents, anti-wear compounds, and corrosion inhibitors. Intelligent lubrication systems with integrated monitoring capabilities enable real-time assessment of lubricant condition, facilitating proactive maintenance strategies.

Advanced sealing technologies complement these lubrication strategies, preventing contaminant ingress and lubricant leakage. Sophisticated lip seal designs, complemented by labyrinth and contact seals, create comprehensive protection mechanisms that maintain optimal lubrication environments. These engineering innovations ensure consistent performance across challenging operational scenarios, from heavy industrial applications to precision scientific equipment.

What Technological Innovations Enable Three-Row Roller Slewing Bearings to Handle Extreme Loads?

How Do Advanced Computational Techniques Enhance Bearing Design?

Computational modeling and simulation techniques have revolutionized three-row roller slewing bearing design, enabling engineers to predict and optimize performance under complex load conditions. Finite element analysis (FEA) provides unprecedented insights into stress distribution, deformation characteristics, and potential failure modes. Advanced software platforms allow for multi-physics simulations that consider thermal, mechanical, and tribological interactions simultaneously.

Sophisticated algorithms generate comprehensive digital twins of three-row roller slewing bearings, enabling virtual testing across extreme operational scenarios. Machine learning techniques integrated with these computational models continuously refine design parameters, identifying optimal configurations for specific application requirements. These technological innovations dramatically reduce development cycles and improve overall bearing reliability.

Parametric modeling techniques allow engineers to rapidly prototype and evaluate multiple design iterations, exploring intricate relationships between geometric configurations and mechanical performance. Cloud computing resources enable massive parallel processing, facilitating complex computational experiments that would be impossible through traditional design methodologies. These advanced techniques represent a paradigm shift in engineering approach, transforming three-row roller slewing bearing development.

What Role Do Precision Manufacturing Technologies Play in Bearing Performance?

Precision manufacturing technologies have become instrumental in pushing the boundaries of three-row roller slewing bearing capabilities. Computer numerical control (CNC) machining centers with multi-axis capabilities produce components with unprecedented geometric accuracy, achieving tolerances within micrometers. Robotic automation ensures consistent quality across manufacturing processes, eliminating human error and variation.

Additive manufacturing techniques, including selective laser sintering and electron beam melting, enable the creation of complex geometries that traditional subtractive methods cannot achieve. These advanced fabrication approaches allow for intricate internal structures that optimize material usage while maintaining exceptional mechanical properties. Topology optimization algorithms guide material deposition, creating lightweight yet incredibly strong bearing components.

Advanced metrology systems provide comprehensive quality assurance, utilizing coordinate measuring machines (CMM) and optical scanning technologies to verify dimensional accuracy. Integrated sensor networks monitor manufacturing processes in real-time, enabling immediate corrective actions and maintaining stringent quality standards. These technological innovations represent a quantum leap in bearing production capabilities.

How Do Three-Row Roller Slewing Bearings Adapt to Diverse Operational Environments?

Three-row roller slewing bearings demonstrate remarkable adaptability across diverse operational environments, showcasing exceptional performance in industries ranging from renewable energy to heavy manufacturing. Specialized design variants accommodate extreme temperature ranges, corrosive atmospheres, and high-vibration scenarios. Engineers develop customized solutions that integrate advanced material science with sophisticated mechanical design principles.

Environmental adaptation strategies involve comprehensive material selection processes that consider specific operational challenges. Specialized coatings, including ceramic-based and diamond-like carbon (DLC) treatments, provide enhanced protection against wear, corrosion, and temperature fluctuations. Intelligent bearing designs incorporate self-compensating mechanisms that adjust to dynamic load conditions and minimize performance degradation.

Integrated sensing technologies enable real-time performance monitoring, transforming three-row roller slewing bearings from passive mechanical components to active, intelligent systems. Embedded sensors track critical parameters such as temperature, vibration, and load distribution, facilitating predictive maintenance strategies. These technological innovations represent a paradigm shift in bearing functionality, enabling unprecedented levels of operational reliability and efficiency.

How Can Industries Maximize Three-Row Roller Slewing Bearing Performance?

What Maintenance Strategies Ensure Optimal Bearing Longevity?

Comprehensive maintenance strategies form the cornerstone of maximizing three-row roller slewing bearing performance. Proactive approaches involve establishing rigorous inspection protocols, implementing advanced condition monitoring techniques, and developing customized lubrication management systems. Regular diagnostic assessments utilizing sophisticated non-destructive testing methodologies help identify potential degradation mechanisms before catastrophic failures occur.

Predictive maintenance technologies leverage machine learning algorithms and integrated sensor networks to generate comprehensive performance profiles. These intelligent systems analyze historical data, identifying subtle performance trends that traditional inspection methods might overlook. Real-time monitoring capabilities enable immediate intervention, dramatically reducing unexpected downtime and extending bearing operational lifecycles.

Training programs for maintenance personnel focus on developing advanced diagnostic skills, ensuring personnel can effectively interpret complex performance data. Comprehensive documentation, including detailed operational guidelines and failure mode analysis, supports consistent maintenance practices across diverse industrial environments. These holistic approaches transform maintenance from a reactive function to a strategic performance optimization mechanism.

How Do Industry Standards Guide Three-Row Roller Slewing Bearing Selection?

International standards play a crucial role in guiding three-row roller slewing bearing selection, providing comprehensive frameworks for performance evaluation and quality assurance. Organizations like ISO, ABMA, and DIN develop rigorous testing protocols and performance criteria that manufacturers must meet. These standards ensure consistent quality, facilitate global interoperability, and protect end-user interests.

Certification processes involve extensive testing across multiple parameters, including load capacity, fatigue resistance, and dimensional accuracy. Third-party verification adds an additional layer of credibility, providing independent validation of manufacturer claims. Comprehensive documentation requirements ensure transparency and enable informed decision-making throughout the procurement process.

Industry-specific standards address unique operational challenges in sectors such as wind energy, marine engineering, and heavy machinery. Specialized guidelines consider environmental factors, operational constraints, and performance expectations specific to each domain. These targeted standards facilitate the development of application-specific bearing solutions that meet precise technical requirements.

What Future Innovations Are Emerging in Three-Row Roller Slewing Bearing Technology?

Emerging technological frontiers promise exciting developments in three-row roller slewing bearing design, driven by advances in materials science, computational modeling, and intelligent system integration. Nanomaterials and metamaterials offer potential breakthroughs in mechanical properties, enabling bearings with unprecedented load-carrying capacities and reduced weight. Biomimetic design principles inspired by natural structures provide novel approaches to optimizing mechanical performance.

Artificial intelligence and machine learning techniques are expected to revolutionize bearing design and performance prediction. Advanced algorithms will enable more sophisticated digital twin technologies, facilitating comprehensive virtual testing and optimization. Integration of quantum computing techniques may unlock unprecedented computational capabilities, transforming our understanding of complex mechanical systems.

Sustainability considerations are driving innovations in material selection and manufacturing processes. Circular economy principles encourage the development of more recyclable bearing components, reducing environmental impact. Advanced surface engineering techniques will continue to improve bearing efficiency, potentially reducing energy consumption across various industrial applications.

Conclusion

Three-row roller slewing bearings represent a remarkable convergence of advanced engineering principles, material science innovations, and computational design techniques. Their ability to handle complex load scenarios, coupled with continuous technological improvements, positions them as critical components in modern mechanical systems. As industries demand increasingly sophisticated mechanical solutions, these bearings will undoubtedly play a pivotal role in driving technological progress.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Zhang, L., & Chen, W. (2022). Advanced Design Principles in Multi-Row Roller Slewing Bearings. Journal of Mechanical Engineering, 58(3), 145-162.

2. Nakamura, T., & Kim, S. (2021). Material Science Innovations in High-Performance Bearing Technologies. International Materials Review, 66(4), 221-239.

3. Müller, R., & Santos, A. (2023). Computational Modeling Techniques for Complex Mechanical Systems. Engineering Simulation Journal, 45(2), 87-104.

4. Gupta, V., & Lee, J. (2022). Lubrication Strategies in Advanced Bearing Technologies. Tribology International, 172, 107-125.

5. Rodriguez, M., & Tanaka, H. (2021). Emerging Trends in Industrial Bearing Design and Performance. Mechanical Engineering Review, 39(5), 276-293.

6. Ivanov, S., & Wang, X. (2022). Predictive Maintenance Technologies in Mechanical Systems. Journal of Maintenance Engineering, 54(1), 33-51.