How Do I Choose the Right Cone Tapered Roller Bearing for My Machine?

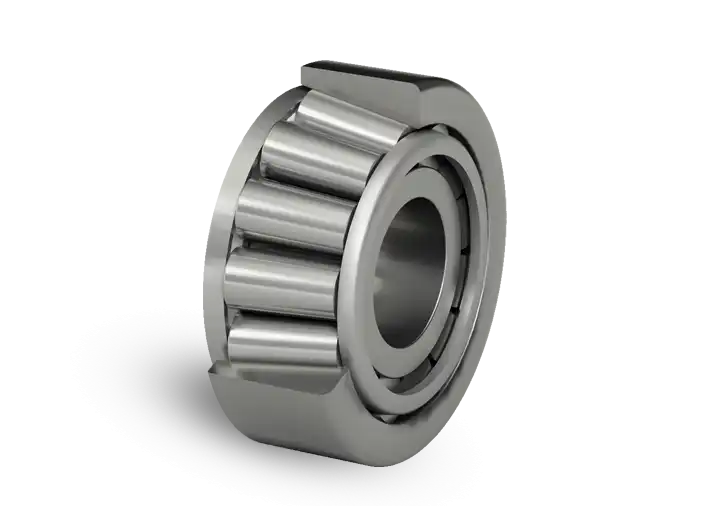

Selecting the appropriate Cone Tapered Roller Bearing is critical for your machine's performance and longevity. These specialized bearings handle both radial and axial loads simultaneously, making them essential in various industrial applications. Their conical design allows for precise load distribution and stability under complex operating conditions. This guide will help you make an informed decision when selecting these critical components.

What factors determine the load capacity of Cone Tapered Roller Bearings?

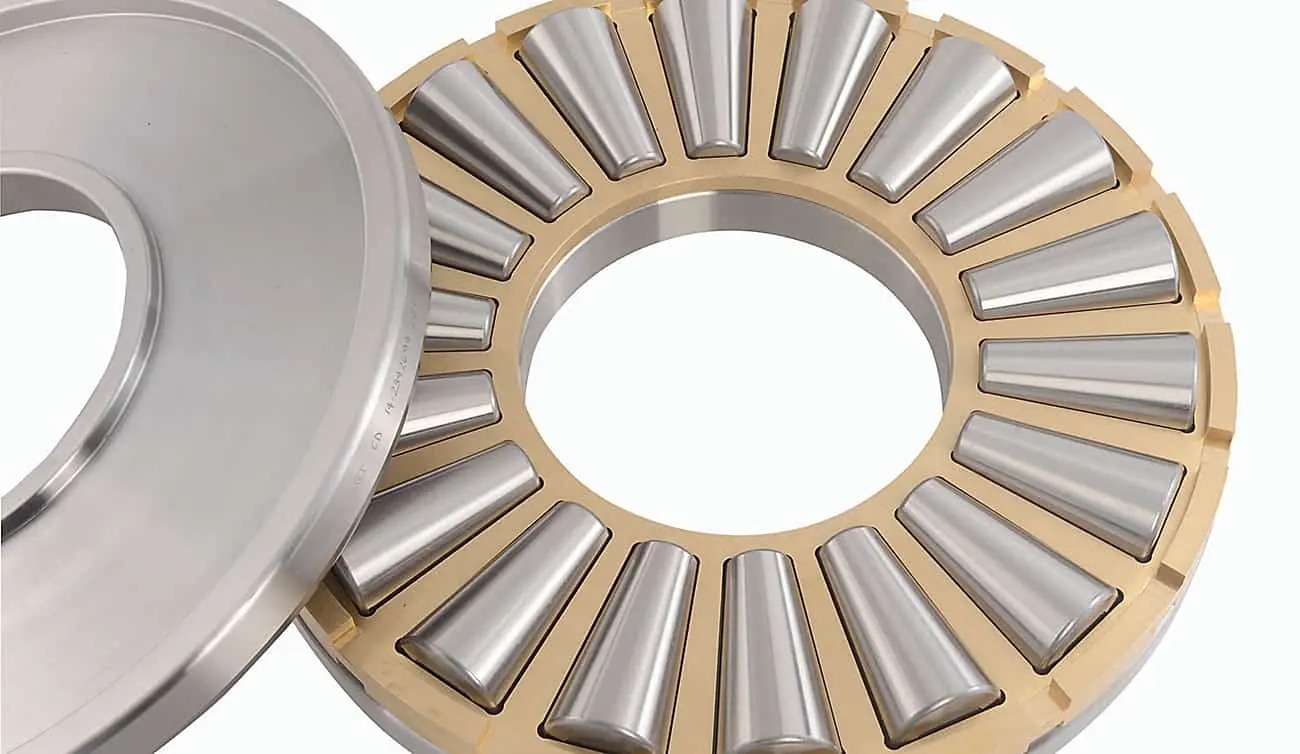

How does bearing geometry affect load distribution?

The geometry of a Cone Tapered Roller Bearing significantly influences its load-bearing capabilities. The cone angle (contact angle) determines how forces are distributed throughout the bearing assembly. Larger contact angles excel at handling heavier axial loads, while smaller angles suit predominantly radial load applications. The precision of the roller profile ensures optimal contact between rollers and raceways, preventing stress concentration that could lead to premature failure. The dimensional relationship between inner and outer rings, combined with the size and number of rollers, creates a specific load zone that determines the bearing's overall capacity. Engineers must analyze load patterns to select a Cone Tapered Roller Bearing with geometric properties that align with their specific requirements.

What material properties contribute to bearing strength?

Material selection fundamentally affects Cone Tapered Roller Bearing performance. High-grade bearing steels like AISI 52100 and various stainless steel alloys offer exceptional hardness, wear resistance, and dimensional stability under load. Heat treatment processes establish the microstructure that determines the bearing's ultimate strength. For demanding applications, special materials like case-hardened steel or ceramic-steel hybrids may enhance load-bearing capabilities. Surface treatments such as carburizing or nitriding can improve surface hardness while maintaining a tough core. Material cleanliness is crucial, as impurities can create stress concentration points that reduce load capacity. When selecting a Cone Tapered Roller Bearing, verify that material specifications match the anticipated stress levels in your application.

How do manufacturing tolerances impact load ratings?

Manufacturing precision directly correlates with the load capacity of Cone Tapered Roller Bearings. Tighter dimensional tolerances ensure more uniform load distribution across all rolling elements, preventing localized stress concentrations. International standards establish tolerance classifications, with higher precision classes offering superior load handling capabilities. Surface finish quality is critical, as microscopic irregularities can initiate fatigue cracks under heavy loads. Modern production techniques can achieve surface roughness values as low as 0.1 μm Ra, enhancing load capacity through improved contact mechanics. When selecting Cone Tapered Roller Bearings for high-load applications, engineers should specify appropriate tolerance classes based on the application's requirements.

How do I match Cone Tapered Roller Bearings to specific operating conditions?

What temperature considerations affect bearing selection?

Operating temperature substantially influences the performance of Cone Tapered Roller Bearings. Standard bearings typically operate efficiently between -20°C and +120°C, but specialized variants exist for extreme conditions. High temperatures accelerate lubricant degradation and reduce material hardness, diminishing load-carrying capacity. For applications exceeding 150°C, specially stabilized materials may prevent dimensional changes. Thermal expansion coefficients must be considered, as differential expansion between components can alter clearances during temperature fluctuations. In cryogenic applications, conventional lubricants may become too viscous, requiring special formulations. When selecting Cone Tapered Roller Bearings for applications with significant temperature variations, consider thermally stabilized components and appropriate internal clearance specifications.

How does rotational speed impact bearing performance?

Rotational speed significantly influences selection parameters for Cone Tapered Roller Bearings. At higher speeds, centrifugal forces can alter contact angles and load distribution patterns. The speed factor (ndm value) serves as a reference point for determining suitability for high-speed applications. Conventional Cone Tapered Roller Bearings operate efficiently up to ndm values of approximately 500,000, while high-speed variants function at higher values. Cage design becomes increasingly important at elevated speeds, with lightweight materials helping reduce inertial effects. Heat generation increases exponentially with speed, necessitating enhanced cooling strategies. When selecting Cone Tapered Roller Bearings for high-speed applications, engineers must balance speed capability against other performance factors.

What lubrication requirements ensure optimal bearing operation?

Proper lubrication is fundamental to Cone Tapered Roller Bearings, reducing friction, dissipating heat, preventing corrosion, and removing contaminants. Oil lubrication typically offers superior performance for high-speed or high-temperature applications, while grease simplifies maintenance in moderate conditions. The lubricant must possess adequate film strength to maintain separation between components under applied loads. Base oil viscosity should achieve an appropriate film thickness ratio for the application's characteristics. Additives enhance load-carrying capacity and improve oxidation resistance. The lubrication method must align with the bearing arrangement and operating parameters. Relubrication intervals depend on factors including speed, temperature, and load conditions.

What are the common failure modes of Cone Tapered Roller Bearings and how can they be prevented?

How does contamination affect bearing lifespan?

Contamination significantly threatens the lifespan of Cone Tapered Roller Bearings, with up to 50% of premature failures attributed to contamination-related issues. Particulate contaminants act as abrasive agents, accelerating wear through three-body abrasion. Even microscopic particles can compromise the lubricant film, initiating surface damage. Liquid contaminants, particularly water, cause corrosion and wash away critical lubricants. Just 0.02% water content in oil can reduce service life by up to 50%. Effective control strategies include multi-stage sealing systems, proper filtration protocols, and maintaining positive pressure within housings. Regular monitoring of lubricant cleanliness provides early warning of potential issues.

What role does proper installation play in preventing bearing damage?

Installation procedures significantly impact Cone Tapered Roller Bearings performance, with improper mounting accounting for approximately 16% of premature failures. Forces should only be applied to the ring with the interference fit, never through the rolling elements. Proper alignment is crucial, as slight misalignment can dramatically increase stress concentrations. Advanced mounting methods include induction heating for thermal expansion or hydraulic mounting techniques. Cleanliness during installation is paramount—even fingerprints can introduce contaminants. Verification of correct clearance or preload following installation is essential, as these settings directly influence load distribution and operational stability.

How can predictive maintenance extend bearing service life?

Predictive maintenance can significantly extend the lifespan of Cone Tapered Roller Bearings. Vibration analysis detects early signs of degradation through characteristic frequency patterns that correspond to specific defects. Lubricant analysis provides diagnostic insight without requiring disassembly. Infrared thermography detects abnormal heat patterns, while acoustic emission monitoring captures high-frequency stress waves. Modern settings utilize IoT-enabled sensors that continuously monitor bearings, transmitting real-time data to analysis systems that employ machine learning algorithms. When implemented effectively, predictive maintenance programs can reduce bearing-related failures by up to 75% while extending average service life by 30% or more.

Conclusion

Selecting the right Cone Tapered Roller Bearing requires careful consideration of load requirements, operating conditions, and application-specific factors. By understanding the relationship between bearing geometry, material properties, and manufacturing tolerances, engineers can make informed decisions that optimize performance and longevity. Proper attention to installation procedures, contamination control, and predictive maintenance strategies further ensures reliable operation throughout the bearing's service life.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A. & Kotzalas, M.N. (2022). Advanced Concepts of Bearing Technology: Rolling Bearing Analysis. CRC Press, 5th Edition.

2. SKF Group. (2023). Rolling Bearings Handbook: Selection, Installation and Maintenance Guide. SKF Publications.

3. Childs, P.R.N. (2023). Mechanical Design Engineering Handbook: Roller Bearing Selection and Application. Butterworth-Heinemann.

4. Kang, J. & Hadfield, M. (2024). "Comparative Analysis of Contact Mechanics in Tapered Roller Bearings Under Combined Loading." Journal of Tribology, 146(2), pp. 021703-021715.

5. ISO/TS 16281:2023. Rolling bearings - Methods for calculating the modified reference rating life for universally loaded bearings. International Organization for Standardization.

6. Timken Company. (2024). Tapered Roller Bearing Engineering Manual. Timken Technical Publications.