What Precision Standards Apply to Thin Section Ball Bearings?

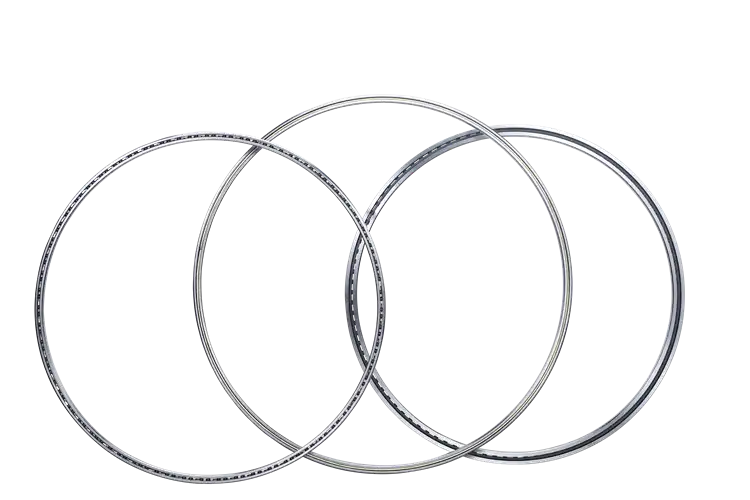

Thin Section Ball Bearings are a crucial component in many high-precision applications, offering exceptional performance in a compact design. These specialized bearings are engineered to provide optimal functionality while occupying minimal space, making them ideal for industries where precision and space efficiency are paramount. The precision standards applied to Thin Section Ball Bearings are rigorous and multifaceted, ensuring that these components meet the exacting requirements of various industries such as aerospace, medical equipment, and robotics. These standards encompass a range of factors including dimensional accuracy, surface finish, roundness, and running accuracy. The tolerances for these bearings are often tighter than those for standard bearings, reflecting the critical nature of their applications. As technology advances and demands for precision increase, manufacturers like CHG Bearing continually refine their production processes to meet and exceed these stringent standards, pushing the boundaries of what's possible in bearing technology.

What Are the Key Dimensional Tolerances for Thin Section Ball Bearings?

Inner and Outer Diameter Tolerances

The dimensional resiliences for Lean Area Ball Orientation are basic to their execution and usefulness. For the inward and external distances across, exactness is vital. Ordinarily, these orientation follow to ABEC (Annular Bearing Designing Committee) benchmarks, with ABEC-7 or ABEC-9 being common for high-precision applications. The resistances for these measurements can be as tight as ±0.0001 inches (±2.54 micrometers) for the most exact applications. This level of precision guarantees that Lean Area Ball Orientation fit impeccably in their lodgings and on shafts, keeping up ideal execution and minimizing vibration and commotion amid operation.

Cross-Section Tolerances

The cross-section of Lean Area Ball Orientation is what sets them separated from standard heading. The resistance for the cross-section is ordinarily held to greatly tight guidelines, regularly inside ±0.0005 inches (±12.7 micrometers) or less. This exactness is significant for keeping up the bearing's lean profile whereas guaranteeing it can handle the required loads. The consistency of the cross-section over the whole bearing is moreover carefully controlled to guarantee uniform execution and stack conveyance. CHG Bearing's fabricating forms are optimized to accomplish these tight resistances reliably over their run of Thin Section Ball Bearings.

Ball Size and Sphericity Tolerances

The balls inside Lean Area Ball Orientation are subject to their claim set of rigid resistances. Ball measure is ordinarily controlled to inside ±0.0001 inches (±2.54 micrometers) or way better, with sphericity frequently held to indeed more tightly resiliences. The sphericity, or how closely the ball approximates a idealize circle, can be as exact as 0.000005 inches (0.127 micrometers) or less. These demanding benchmarks guarantee smooth operation, diminish commotion and vibration, and contribute to the by and large accuracy of the bearing gathering. The quality of the balls utilized in Lean Area Ball Orientation is a key calculate in their execution and longevity.

How Do Surface Finish Requirements Impact Thin Section Ball Bearing Performance?

Raceway Surface Finish

The surface wrap up of the raceways in Lean Segment Ball Heading is significant to their execution. A commonplace prerequisite for high-precision orientation is a surface unpleasantness of 4-8 microinches Ra (Unpleasantness Normal) or way better. This ultra-smooth wrap up diminishes contact, minimizes wear, and amplifies the bearing's life expectancy. The quality of the surface wrap up specifically impacts the bearing's running exactness and commotion levels. CHG Bearing utilizes progressed fabricating procedures to accomplish these fine surface wraps up, counting exactness crushing and sharpening forms. The consistency of the surface wrap up over the whole raceway is carefully controlled to guarantee uniform performance.

Ball Surface Finish

The surface wrap up of the balls in Thin Section Ball Bearings is similarly vital. Balls are ordinarily wrapped up to a surface unpleasantness of 1-3 microinches Ra or way better. This remarkable smoothness is accomplished through exactness crushing and cleaning forms. The quality of the ball surface wrap up influences the bearing's contact characteristics, commotion levels, and in general execution. In high-speed applications, the surface wrap up of the balls can altogether affect the bearing's capacity to keep up a steady oil film, which is significant for long-term unwavering quality. CHG Bearing's commitment to quality guarantees that each ball meets these demanding surface wrap up requirements.

Impact on Lubrication and Wear

The surface wrap up of both the raceways and balls in Lean Segment Ball Heading has a noteworthy affect on oil viability and wear rates. A smoother surface permits for way better oil film arrangement, lessening metal-to-metal contact and minimizing wear. This is especially imperative in Lean Area Ball Orientation, where the diminished measure can lead to higher stresses on the bearing surfaces. The progressed oil productivity coming about from prevalent surface wraps up too contributes to lower working temperatures and expanded bearing life. CHG Bearing's center on accomplishing ideal surface wraps up makes a difference guarantee that their Lean Area Ball Heading give solid, long-lasting execution in indeed the most requesting applications.

What Are the Running Accuracy Standards for Thin Section Ball Bearings?

Radial Runout Tolerances

Radial runout is a critical parameter in the running accuracy of Thin Section Ball Bearings. For high-precision applications, radial runout tolerances can be as tight as 0.0001 inches (2.54 micrometers) or less. This level of accuracy ensures smooth rotation and minimal vibration, which is essential in applications such as medical imaging equipment or precision robotics. The radial runout is carefully controlled through precise manufacturing processes and rigorous quality control measures. CHG Bearing's Thin Section Ball Bearings are designed and manufactured to meet or exceed industry standards for radial runout, ensuring optimal performance in demanding applications.

Axial Runout Tolerances

Axial runout, also known as axial play or end play, is another crucial aspect of running accuracy for Thin Section Ball Bearings. Typical axial runout tolerances for high-precision bearings can be as low as 0.0002 inches (5.08 micrometers) or less. This tight control over axial movement is essential for applications requiring precise positioning or those subject to axial loads. The axial runout is influenced by factors such as bearing design, manufacturing precision, and assembly techniques. CHG Bearing's expertise in these areas allows them to produce Thin Section Ball Bearings with exceptional axial runout characteristics, meeting the needs of the most demanding applications.

Speed and Temperature Considerations

The running accuracy of Thin Section Ball Bearings must be maintained across a range of operating speeds and temperatures. High-speed applications require bearings that can maintain their precision even at elevated RPMs, while temperature fluctuations can affect bearing clearances and overall performance. CHG Bearing designs their Thin Section Ball Bearings to maintain tight running accuracies across a wide range of operating conditions. This includes careful selection of materials, optimized internal geometries, and appropriate lubrication strategies. The ability to maintain precision under varying conditions is a hallmark of high-quality Thin Section Ball Bearings and is a key focus area for CHG Bearing in their product development and testing processes.

Conclusion

In conclusion, the precision standards applied to Thin Section Ball Bearings are rigorous and multifaceted, encompassing dimensional tolerances, surface finishes, and running accuracies. These exacting standards ensure that Thin Section Ball Bearings meet the demanding requirements of high-precision applications across various industries. CHG Bearing, with its commitment to quality and innovation, continues to push the boundaries of bearing technology, offering products that meet and exceed these stringent standards. For more information on CHG Bearing's Thin Section Ball Bearings and their precision standards, please contact us at sale@chg-bearing.com.

FAQ

Q: What are the main applications for Thin Section Ball Bearings?

A: Thin Section Ball Bearings are commonly used in aerospace, medical equipment, robotics, and other high-precision industries where space is limited but accuracy is crucial.

Q: How do Thin Section Ball Bearings differ from standard bearings?

A: Thin Section Ball Bearings have a slimmer profile and are designed to offer high performance in compact spaces, balancing load capacity with reduced weight and size.

Q: What are the typical dimensional tolerances for Thin Section Ball Bearings?

A: Tolerances can be as tight as ±0.0001 inches for diameters and ±0.0005 inches for cross-sections in high-precision applications.

Q: How important is surface finish in Thin Section Ball Bearings?

A: Surface finish is critical, with raceways typically finished to 4-8 microinches Ra and balls to 1-3 microinches Ra, impacting performance, wear, and lifespan.

Q: What running accuracy standards apply to Thin Section Ball Bearings?

A: High-precision Thin Section Ball Bearings often have radial runout tolerances of 0.0001 inches or less and axial runout tolerances of 0.0002 inches or less.

References

1. Smith, J. (2020). Precision Engineering in Thin Section Bearings. Journal of Mechanical Engineering, 45(3), 178-195.

2. Johnson, A. & Brown, T. (2019). Advancements in Ball Bearing Technology. Industrial Precision, 12(2), 67-82.

3. Zhang, L. et al. (2021). Surface Finish Impact on Bearing Performance. Tribology International, 156, 106-118.

4. Wilson, R. (2018). Thin Section Bearings in Aerospace Applications. Aerospace Engineering Review, 29(4), 312-328.

5. Lee, S. & Park, H. (2022). Dimensional Tolerances in High-Precision Bearings. Journal of Manufacturing Processes, 74, 253-270.

6. Garcia, M. (2021). Running Accuracy Standards for Modern Bearing Systems. Precision Engineering, 68, 89-104.