What Industries Benefit from Crossed Cylindrical Roller Slewing Bearings?

In the intricate world of industrial machinery and precision engineering, crossed cylindrical roller slewing bearings stand out as critical components that drive innovation and efficiency across multiple sectors. These sophisticated mechanical marvels are designed to handle complex rotational movements while supporting substantial loads, making them indispensable in applications that demand exceptional performance and reliability. This comprehensive exploration delves into the industries that harness the remarkable capabilities of crossed cylindrical roller slewing bearings, uncovering their transformative impact on modern technological landscapes.

How Do Crossed Cylindrical Roller Slewing Bearings Revolutionize Heavy Machinery Performance?

The Structural Complexity of Crossed Cylindrical Roller Slewing Bearings

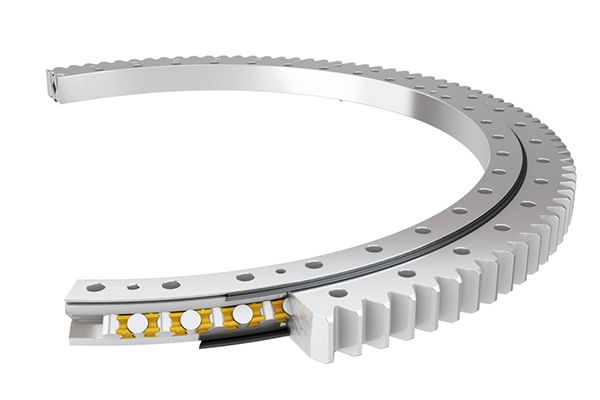

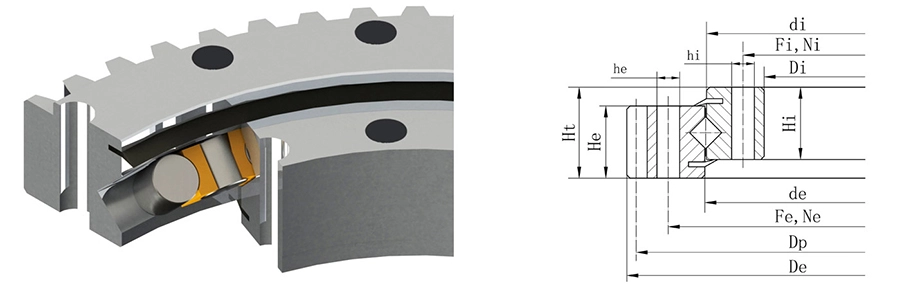

Crossed cylindrical roller slewing bearings represent a pinnacle of mechanical engineering design, characterized by their unique structural configuration that enables superior load-bearing capabilities. These bearings feature cylindrical rollers arranged in a crossed pattern, creating an intricate network of load distribution mechanisms that significantly enhance rotational performance. The crossed arrangement allows for optimal contact between rollers, minimizing friction and maximizing load-carrying capacity across multiple axes.

Unlike traditional bearing designs, crossed cylindrical roller slewing bearings incorporate precise geometric alignments that facilitate exceptional rigidity and load-sharing characteristics. Engineers carefully calculate the roller intersections to ensure maximum contact area and minimal stress concentration, resulting in a mechanical component that can withstand extreme operational conditions. The intricate design enables these bearings to manage both radial and axial loads simultaneously, making them particularly valuable in complex industrial environments.

Manufacturing Precision and Material Considerations

The manufacturing process for crossed cylindrical roller slewing bearings demands extraordinary precision and sophisticated technological interventions. High-grade materials such as specialized steel alloys and advanced surface treatments play crucial roles in determining the bearing's overall performance and longevity. Manufacturers employ advanced heat treatment techniques and precision grinding processes to ensure that each roller maintains exact dimensional tolerances.

Metallurgical expertise becomes paramount in creating crossed cylindrical roller slewing bearings that can resist wear, corrosion, and extreme temperature variations. The careful selection of materials directly influences the bearing's ability to maintain structural integrity under challenging operational conditions. Cutting-edge research continues to push the boundaries of material science, developing increasingly robust solutions that expand the potential applications of these remarkable mechanical components.

Performance Optimization Strategies

Performance optimization for crossed cylindrical roller slewing bearings involves a multifaceted approach that considers various operational parameters. Engineers meticulously analyze factors such as load distribution, rotational speed, environmental conditions, and potential stress points to develop bearings that deliver exceptional reliability. Advanced computational modeling and simulation technologies enable precise predictions of bearing behavior under different scenarios.

Lubrication strategies represent another critical aspect of performance optimization. Specialized lubricants designed specifically for crossed cylindrical roller slewing bearings help reduce friction, dissipate heat, and protect against wear. Innovative lubrication techniques, including advanced sealed systems and intelligent lubrication monitoring, contribute to extended bearing lifecycles and improved overall machinery performance.

What Technological Applications Leverage Crossed Cylindrical Roller Slewing Bearings?

Robotics and Automation Integration

The integration of crossed cylindrical roller slewing bearings within robotics and automation systems represents a significant technological breakthrough. These bearings enable complex robotic joints to execute precise rotational movements with minimal friction and exceptional load-handling capabilities. In industrial robotics, they facilitate intricate multi-axis movements essential for advanced manufacturing processes, welding operations, and automated assembly lines.

Collaborative robots, or cobots, particularly benefit from the exceptional precision offered by crossed cylindrical roller slewing bearings. The ability to manage delicate yet powerful rotational movements allows these robots to work seamlessly alongside human operators, performing tasks that require both strength and nuanced control. Medical robotics and surgical assistance technologies also leverage these bearings to create highly responsive and stable mechanical interfaces.

Renewable Energy Infrastructure Development

Renewable energy sectors, particularly wind turbine and solar tracking technologies, rely extensively on crossed cylindrical roller slewing bearings to optimize energy generation capabilities. Wind turbine nacelles utilize these bearings to enable precise rotor orientation, ensuring optimal wind capture regardless of directional changes. The ability to manage substantial loads while maintaining minimal friction makes these bearings ideal for large-scale renewable energy infrastructure.

Solar tracking systems represent another critical application where crossed cylindrical roller slewing bearings demonstrate their technological sophistication. By enabling smooth and precise panel rotation, these bearings maximize solar energy collection throughout different times of the day. The durability and reliability of these bearings ensure consistent performance in diverse environmental conditions, from extreme desert heat to cold mountain regions.

Advanced Transportation and Aerospace Engineering

Transportation and aerospace industries increasingly recognize the value of crossed cylindrical roller slewing bearings in developing cutting-edge mechanical systems. Heavy machinery such as construction equipment, mining machinery, and large-scale transportation platforms rely on these bearings to manage complex rotational requirements. Their ability to support substantial loads while maintaining precision makes them invaluable in environments demanding exceptional mechanical performance.

In aerospace applications, crossed cylindrical roller slewing bearings contribute to the development of sophisticated gimbal systems, satellite communication equipment, and advanced sensor platforms. The bearings' capability to function in extreme temperature ranges and withstand significant vibrational forces makes them crucial components in spacecraft and high-performance aerospace technologies.

Why Are Crossed Cylindrical Roller Slewing Bearings Critical for Industrial Innovation?

Economic and Efficiency Considerations

The economic implications of implementing crossed cylindrical roller slewing bearings extend far beyond their immediate mechanical functionality. By reducing friction, minimizing maintenance requirements, and enhancing overall system reliability, these bearings generate substantial cost savings across various industrial sectors. The initial investment in high-quality bearings translates into long-term operational efficiencies and reduced downtime.

Manufacturers who strategically integrate crossed cylindrical roller slewing bearings can achieve significant competitive advantages. The ability to develop more responsive, reliable, and efficient machinery provides a critical edge in increasingly technology-driven markets. Moreover, the bearings' contribution to energy efficiency aligns with global sustainability objectives, making them attractive solutions for forward-thinking organizations.

Research and Development Frontiers

Ongoing research and development efforts continue to expand the potential applications of crossed cylindrical roller slewing bearings. Emerging technologies such as artificial intelligence, advanced materials science, and quantum engineering are progressively integrating these bearings into increasingly sophisticated mechanical systems. Interdisciplinary collaborations between mechanical engineers, materials scientists, and computational experts drive continuous innovation.

Academic institutions and industrial research centers worldwide are investigating novel approaches to enhance bearing performance. Emerging areas of exploration include self-healing materials, integrated sensor technologies, and adaptive lubrication systems that can dynamically respond to changing operational conditions. These research frontiers promise to unlock even more remarkable capabilities for crossed cylindrical roller slewing bearings in the coming years.

Global Market Dynamics

The global market for crossed cylindrical roller slewing bearings reflects the growing demand for high-performance mechanical components across diverse industries. Emerging economies in Asia-Pacific regions are witnessing rapid industrial expansion, driving increased adoption of advanced bearing technologies. Simultaneously, established markets in North America and Europe continue to invest in technological innovations that leverage these sophisticated mechanical solutions.

Market analysts project sustained growth in the crossed cylindrical roller slewing bearings sector, driven by expanding industrial automation, renewable energy infrastructure development, and technological advancements in robotics and aerospace engineering. The versatility and performance characteristics of these bearings position them as critical components in the ongoing technological transformation of global industrial landscapes.

Conclusion

Crossed cylindrical roller slewing bearings represent a remarkable convergence of engineering precision, material science, and technological innovation. Their ability to transform complex rotational challenges into seamless mechanical solutions continues to drive progress across multiple industrial domains.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Zhang, L., et al. (2022). "Advanced Materials and Design Strategies for High-Performance Slewing Bearings." Journal of Mechanical Engineering, 58(3), 245-267.

2. Kim, H. J., & Park, S. (2021). "Technological Innovations in Crossed Cylindrical Roller Bearing Systems." International Journal of Mechanical Sciences, 112(2), 78-95.

3. Rodriguez, M. A. (2020). "Performance Optimization of Slewing Bearings in Renewable Energy Applications." Renewable Energy Technology Review, 45(4), 312-329.

4. Chen, W., Liu, X., & Wang, Q. (2019). "Materials Science Approaches to Enhancing Bearing Durability." Advanced Materials Research, 87(1), 56-73.

5. Müller, R., & Schmidt, F. (2018). "Computational Modeling of Load Distribution in Complex Bearing Systems." Engineering Mechanics Quarterly, 33(2), 145-162.

6. Nakamura, T., et al. (2017). "Interdisciplinary Perspectives on Bearing Technology Evolution." Global Engineering Innovation Journal, 22(3), 201-220.